Draining the cooling oil:

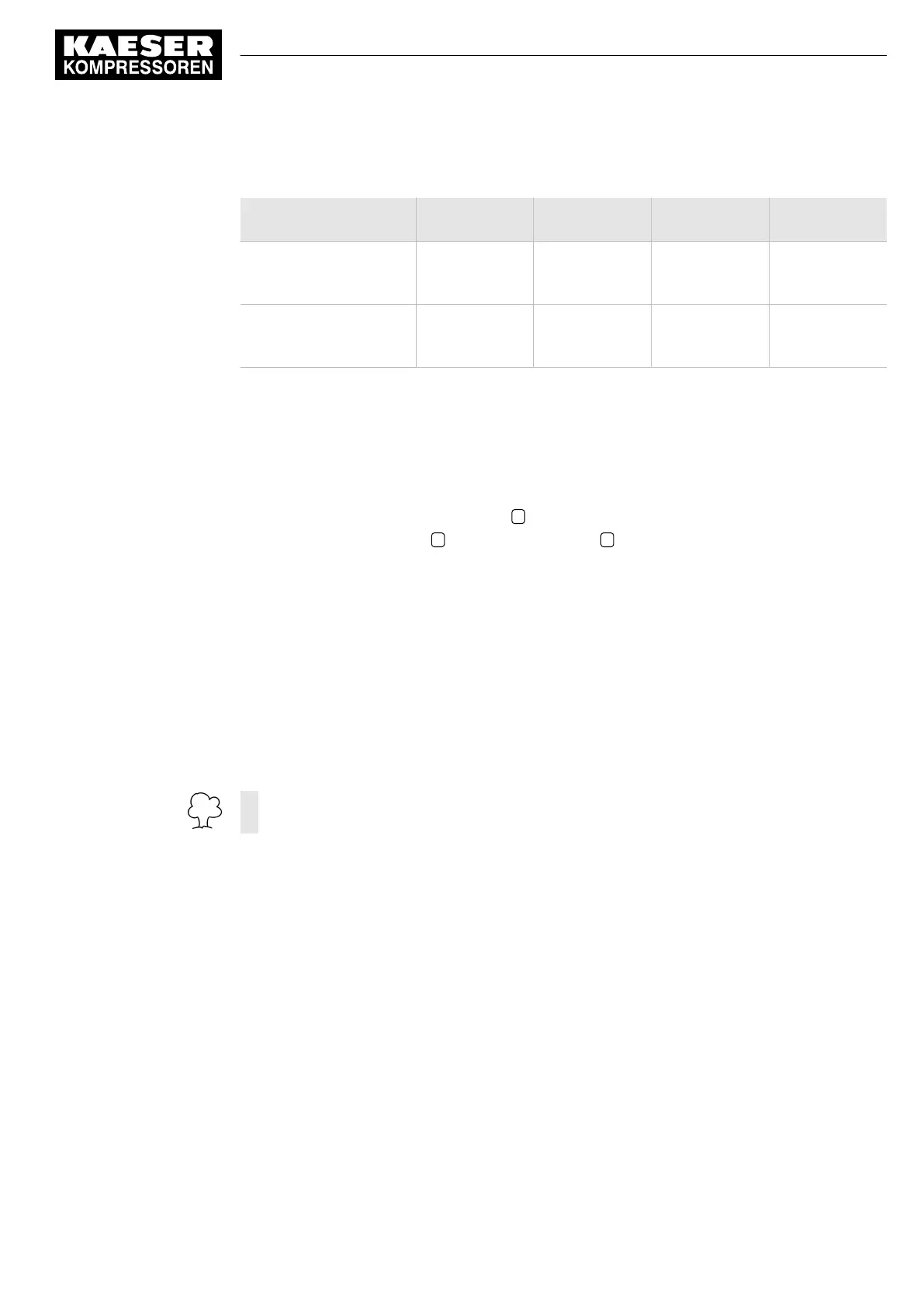

Machine status Protective cap Hose coupling Oil drain valve

status

1 Mode

(machine runs)

connected is supplied with

the machine as

accessory.

closed

2 Oil drain

(Machine de‐

commissioned)

removed connected open

Tab. 87 Oil drain valve

1. Unscrew the filler plug in the oil separator tank.

2.

In Option oe (sealed floor pan), the bung must be removed from the floor panel.

3. Position a receptacle beneath the airend (accessible through a hole in the floor panel).

4. Lead the hose through the hole in the floor panel and into the receptacle, securing it in place.

5. Loosen and remove the locking lever 6

.

6.

Screw the hose coupling 7

onto the oil drain valve 5 .

Cooling oil drains.

7.

Unscrew and remove the hose coupling.

The oil drain valve is again closed.

8. Close the oil discharge valve with the sealing cap.

9. In Option oe (sealed floor pan), you must also close the opening in the floor panel, using the

bung.

Finish off the work steps

1. Replace the plug in the oil separator tank filling port.

2. Close the canopy.

Dispose of used oil and oil-contaminated working materials according to environmental pro‐

tection regulations.

Further information See chapter 10.4.2 for oil filling.

10.4.4 Replace the compressor oil filter

Material Spares

Tool

Receptacle

Cleaning cloth

Precondition The machine is shut down.

The machine is fully vented, the pressure gauge reads 0 psig.

The machine is cooled down.

All compressed air consumers are disconnected and the air outlet valves are open.

Negative cable to the batteries disconnected.

10 Maintenance

10.4 Compressor Maintenance

No.: 9_9548 05 USE

Operator Manual Screw Compressor

M27

133

Loading...

Loading...