10 Parameter List

174 of

212

PumpDrive 2

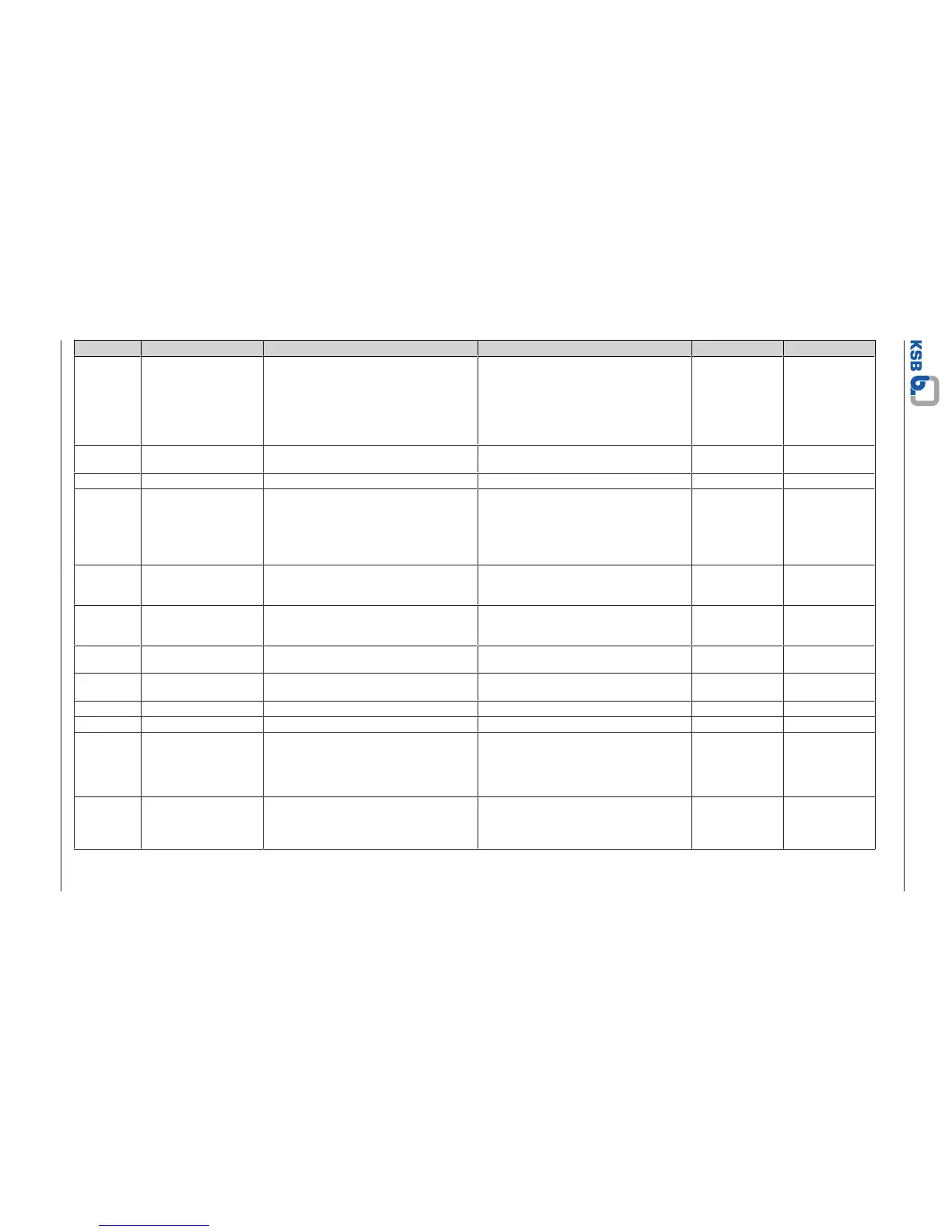

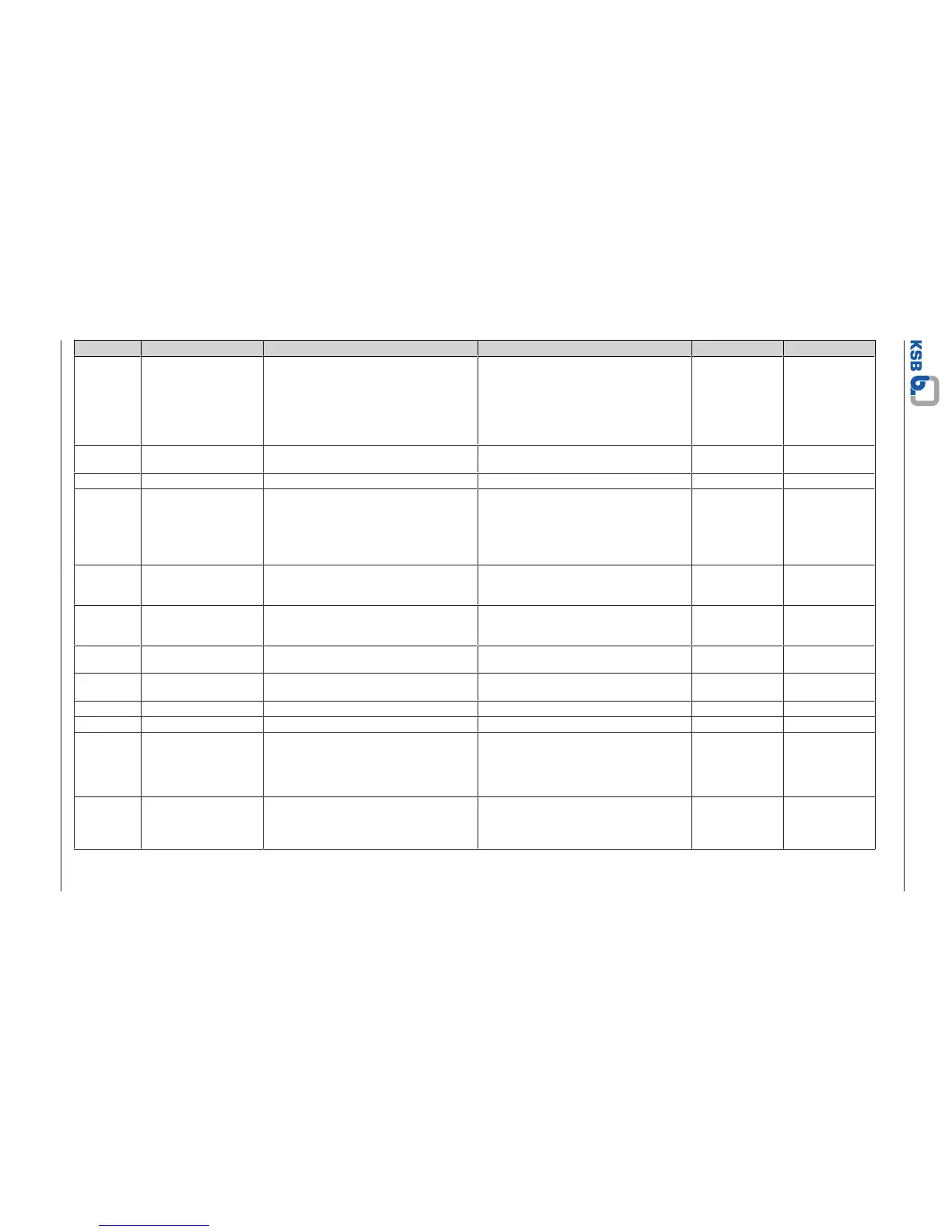

Parameter Description Help text Possible settings Unit Factory setting

3-9-1-2 Time Delay Time delay before the message (warning or

alert) is triggered. In a redundant system,

only a warning is output as the auxiliary

master can assume the function. Only if the

actual value also fails at the auxiliary master

is the alert output, which then triggers the

specified response to actual value failure.

0,0 … 10,0 s 0,5

3-9-1-3 Speed During Failure Fixed speed that is activated when the

actual value fails

3-2-2-1 … 3-2-2-2 rpm 3-2-2-1

3-9-2 Functional Check Run

3-9-2-1 Automatic Functional

Check Run

For a functional check run, a pump is

started, run at a configurable frequency for

a configurable period of time and then

stopped again. During this period, the

pump is not available for closed-loop

control operation.

▪ OFF

▪ After Idle Period

▪ After Idle Period at Defined Time

OFF

3-9-2-2 Idle Period before

Functional Check Run

A functional check run is performed for a

pump if it has not been started for the

defined period of time.

0…168 h 24

3-9-2-3 Time for Functional

Check Run

When a time has been defined, the

functional check run after idle period is

delayed until the defined time is reached.

00:00…23:59 00:00

3-9-2-4 Functional Check Run

Duration

Runtime of pump during the functional

check run at the set speed

0.0 … 600.0 s 5,0

3-9-2-5 Speed for Functional

Check Run

Speed for Functional Check Run 3-2-2-1 … 3-2-2-2 rpm 500

3-9-3 Dyn Press Comp

3-9-3-1 Dynamic Pressure

Compensation Method

Selecting the dynamic differential pressure

compensation method (DFS) Dynamic

pressure compensation based on speed can

only be used for systems without a geodetic

head (e.g. in closed systems).

▪ OFF

▪ Speed

▪ Flow rate

OFF

3-9-3-2 Dyn Press Comp Q Data

Point

The setpoint compensation value is reached

at this point. Beyond that, the setpoint is

further increased with respect to the

specified value.

Minimum to maximum limit of value range

set

Dependent on the

unit set

0,0

Loading...

Loading...