Chapter 5 Positioning Instructions

5 - 10

• The instruction only sets the item of the operation data, and the basic parameter items related to

the operation such as the bias speed and speed limit are fixed in the positioning basic parameters.

• If you use the DST instruction, the operation pattern is fixed as End operation, and the operation

method is fixed as the single operation. But if continued operation or repeated operation is needed,

use indirect starting (IST instruction).

(b) Error

• If the value designated as ax (instruction axis) is other than 0 and 1, the error flag (F110) is set

and the instruction is not executed.

• This case if an error of execution of the instruction, so the error of positioning area K flag (axis

X:K4201, axis Y: K4301) does not turn On.

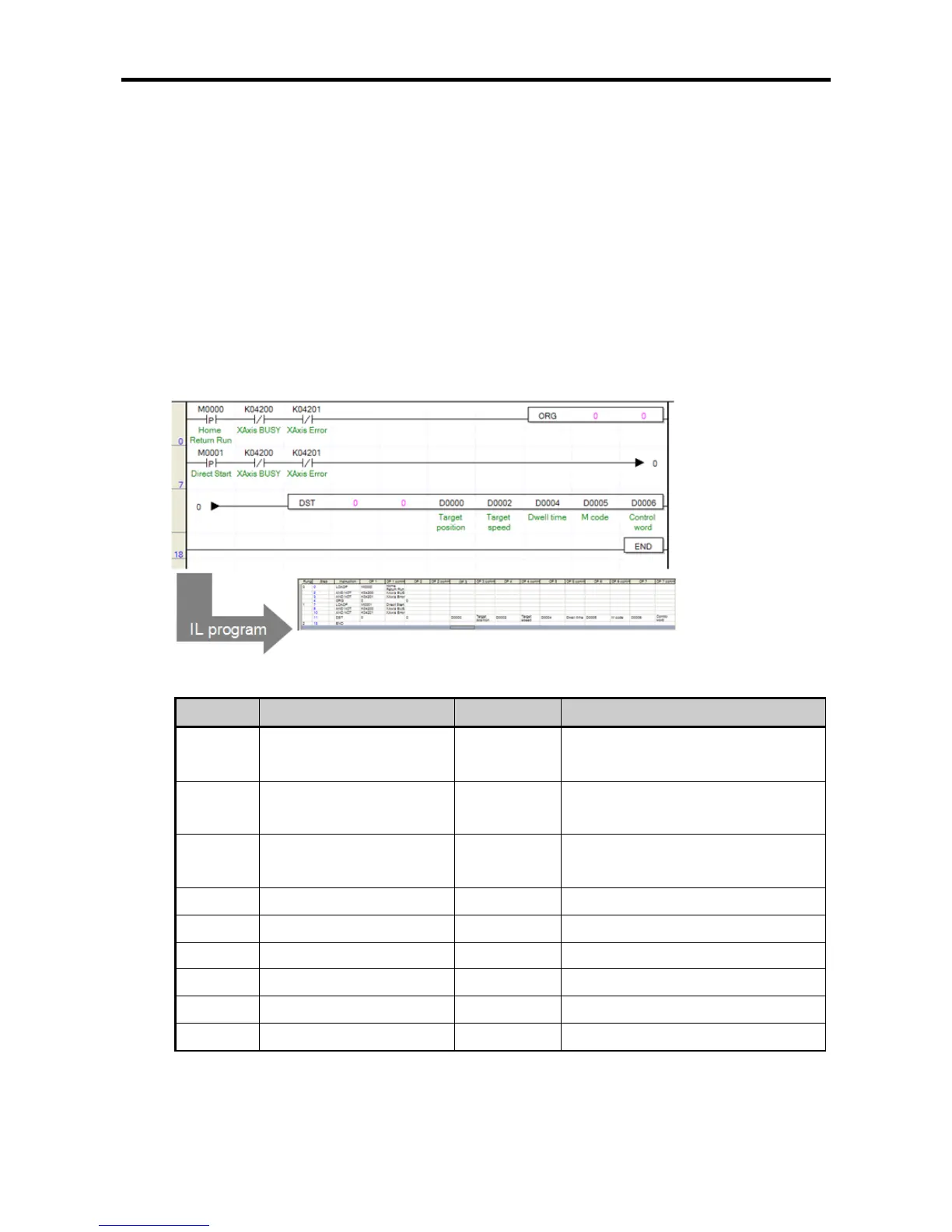

(2) Example of Use of the Instruction

• Direct starting instruction is described with the example of the following program.

• The example of use of the DST instruction is described on the basis of axis X.

(a) Example of the Program

(b) Device Used

※ H`20 : Bit5~6 : 1 (No.2 acceleration/deceleration pattern), Bit 4 : 0 (absolute coordinates),

Bit0 : 0(position control)

Loading...

Loading...