Chapter 5 Positioning Instructions

5 - 14

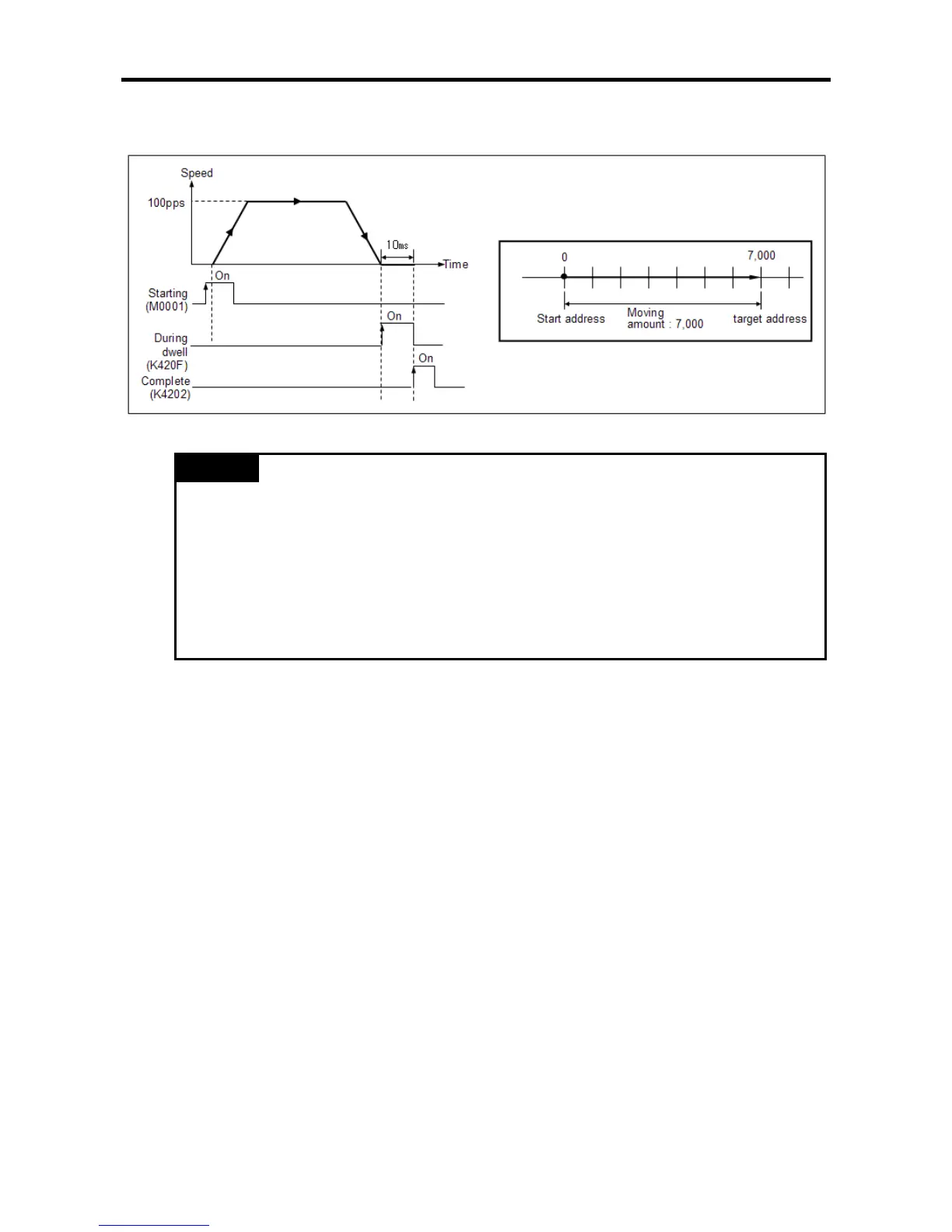

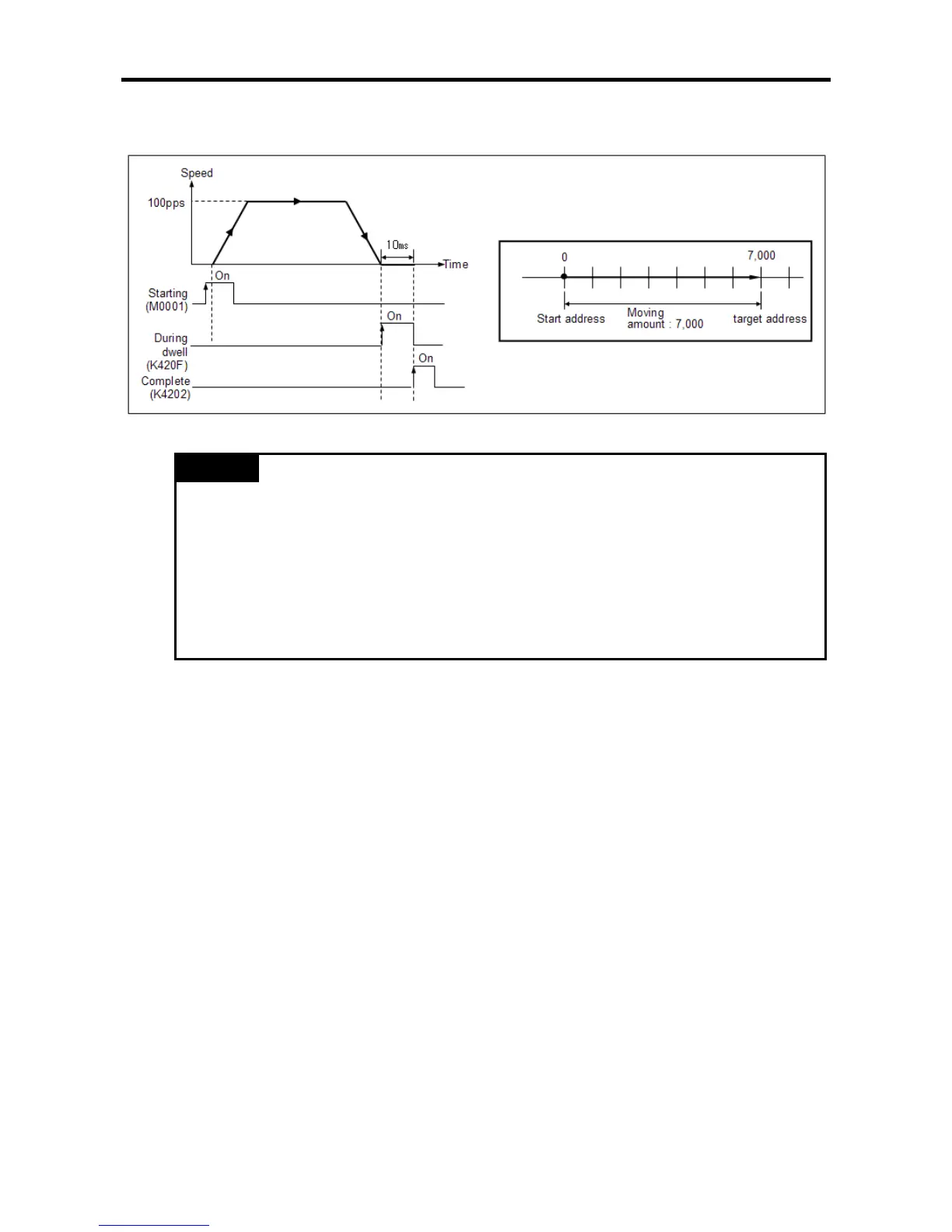

2) Since M code is set at 0, it does not appear and as the operation pattern is End, the step

number (axis X:K426) of area K is changed into 4, which is step + 1.

Remark

• In addition to executing indirect operation by using the IST instruction, indirect starting can also

be started by using the starting signal instruction contact point (axis X:K4290, axis Y:K4390) of

area K.

If starting is done by using the starting signal instruction contact point, the operation step is

fixed at the current operation step number (axis X:K426, axis Y:K436).

Therefore if you want to change the operation step when starting by using the starting signal

instruction contact point, change the operation step by using the Starting step number

changing instruction and turn on the starting instruction contact point.

Loading...

Loading...