Chapter 3 Before positioning

3- 13

3.1.8 Sync control

•In sync control, position or speed of subsidiary axis is synchronized with that of main axis. There are

two types in sync control, speed sync control and position sync control.

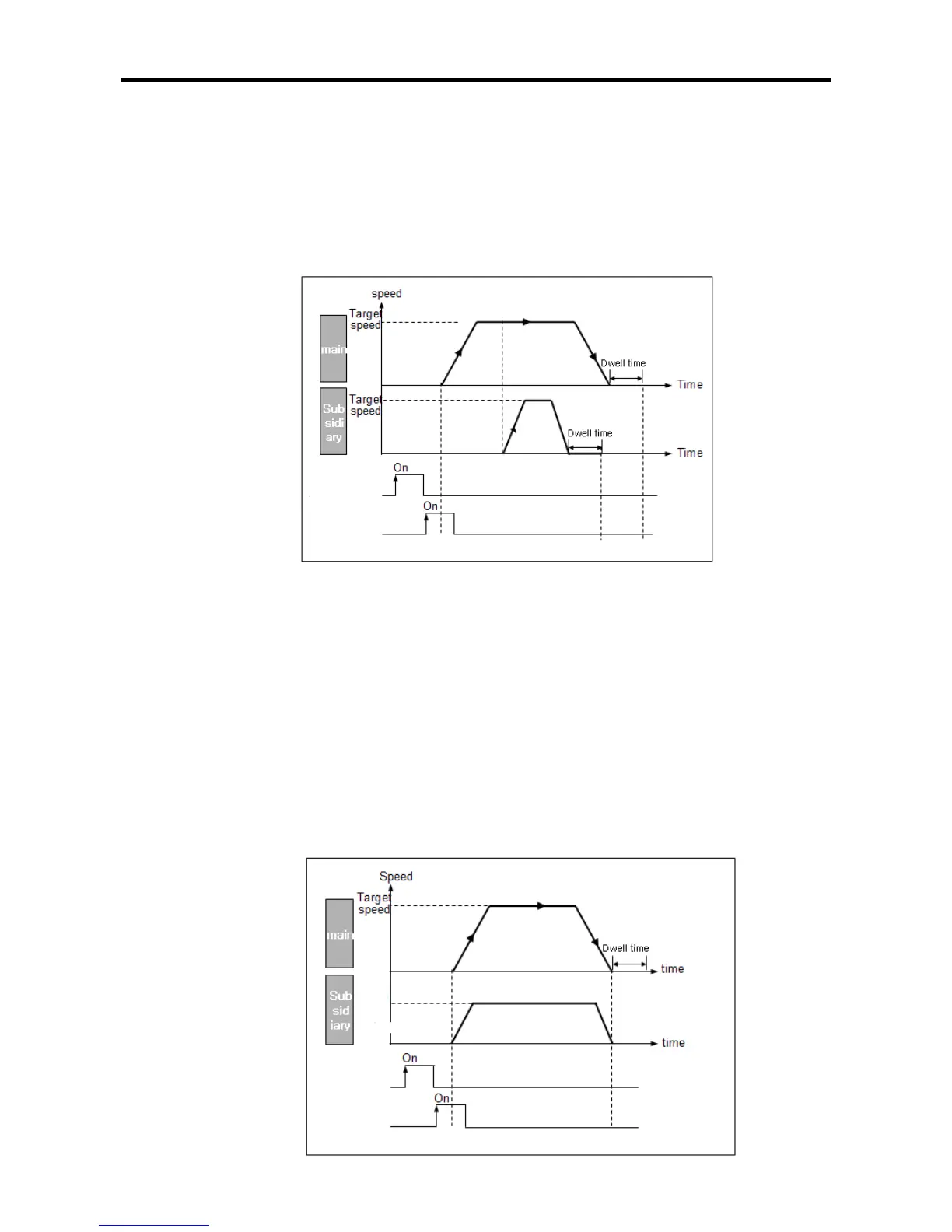

(1) Position sync control

• Position sync control means starting the operation step of subsidiary at the time when position of

main axis is same with position set in SSP instruction (Sync control)

• Position sync control can be executed when origin of both axes is determined. When executing

the SSP instruction, if origin of main axis is not determined, error code 346 occurs and for

subsidiary axis, error code 344.

• When using SST instruction, specify the main axis to be different with subsidiary axis. If not, error

code 347 will occur.

• If synch control is executed, though pulse is not yielded until main axis goes to designated axis,

flag indicating whether subsidiary axis moves or not, turns on (X axis: K4200, %KX6720, Y axis:

K4300, %KX6880).

• After executing position sync control, if the user wants to cancel the execution of position sync

control, execute the STP instruction (stop command).

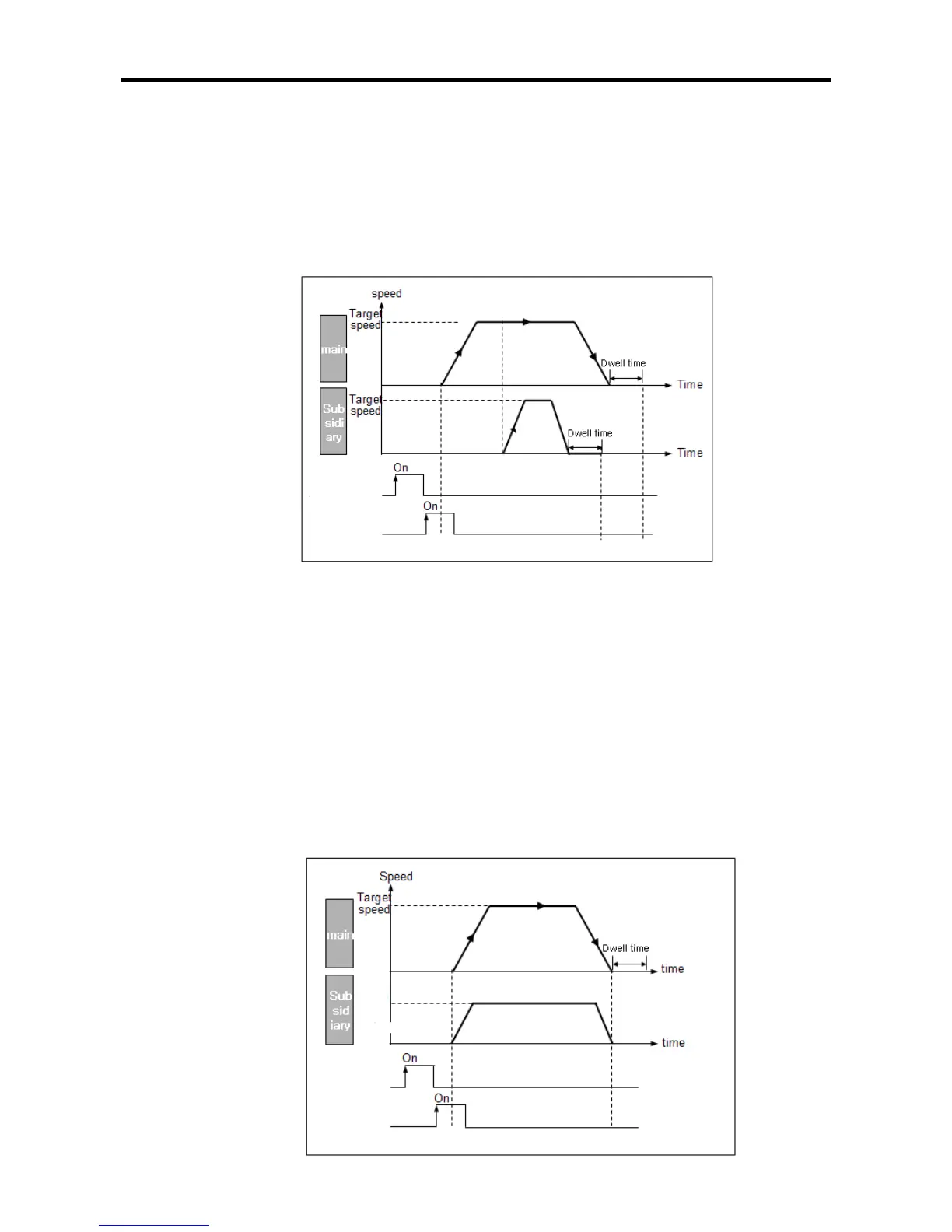

(2) Speed sync control

• If main axis starts as figure below, subsidiary axis moves with speed of sync speed rate set in

the SSS instruction (speed sync command).

Sync position

Start Position

sync

Loading...

Loading...