Chapter 3 Before positioning

3- 42

(1) Step number

• The range of positioning data serial number is between 1 ~ 30.

(compact standard/high-end type is 1~80)

• When executing indirect start, simultaneous start, linear interpolation operation, position

synchronization and etc., if you designates the step number of data to operate, it operates

according to positioning dedicated K area where operation data is saved.

• If step number is set as 0, operation step indicated at the current step number (X axis:

K426(%KW426), Y axis: K436(%KW436)) of positioning monitor flag is operated.

Remark

• The user can use variable of dedicated K area per each step easily by using Register U

Device. For detail of monitor registration of positioning, refer to XG5000 user manual.

(2) Coordinates

• Here sets the coordinates method of relevant operation step data.

• Coordinates methods selectable are absolute coordinate and Incremental coordinate.

• For more detail, refer to 3.1.2.

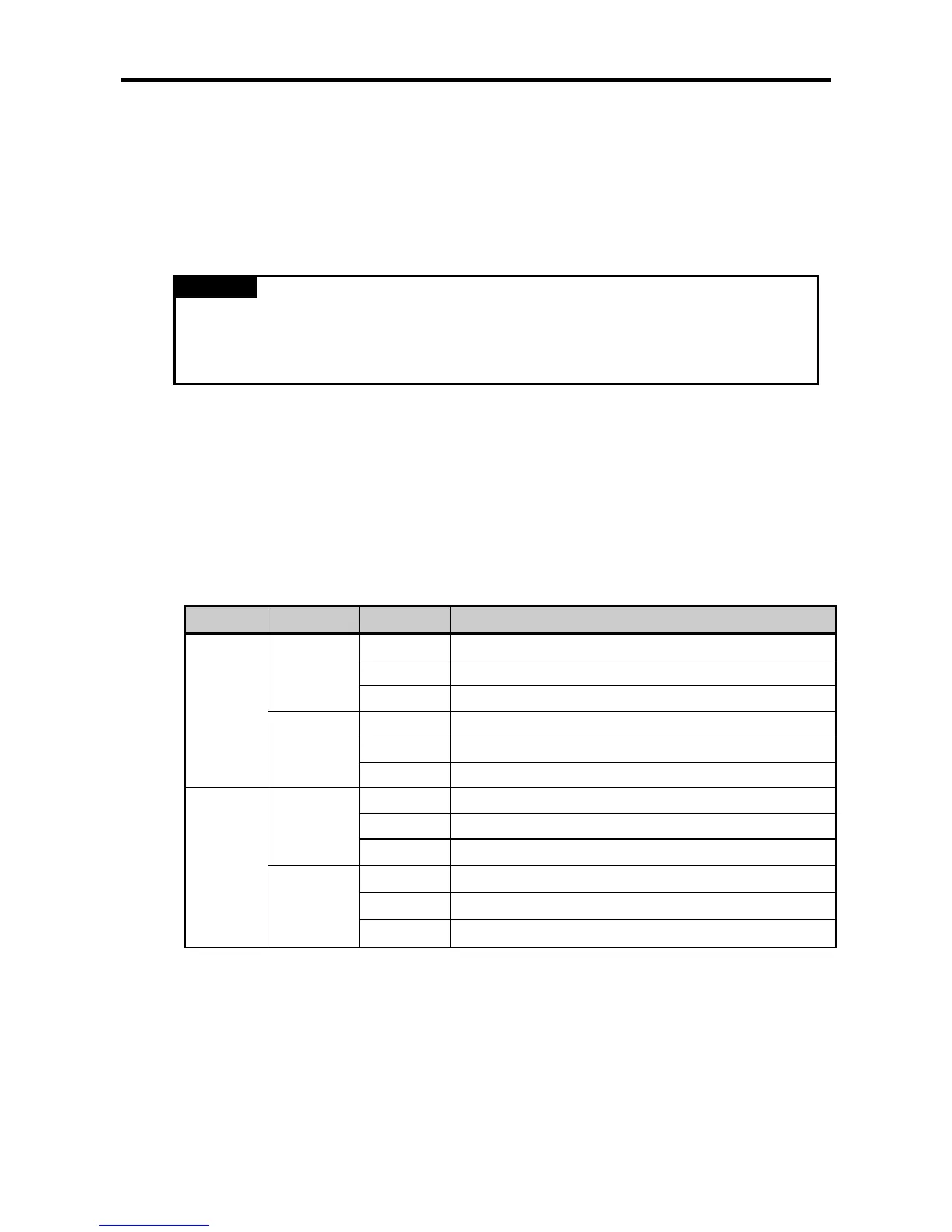

(3) Operation pattern (END/KEEP/CONT) and operation method (SIN/REP)

• The user can select one pattern among three operation patterns per step. It can configure how to

use the positioning operation data.

• Operation pattern can be set as follows according to Control and Method on the operation data.

Control Method Pattern Reference

POS

SIN

END

KEEP

CONT Linear interpolation is not available

REP

END

KEEP

CONT Linear interpolation is not available

SPD

SIN

END Linear interpolation is not available

KEEP Linear interpolation is not available

CONT Not available

REP

END Linear interpolation is not available

KEEP Linear interpolation is not available

CONT Not available

• In case Method is set as SIN, the next operation step become ‘current operation step + 1’. And in

case Method is set as REP, the next operation step become the step set in REP Step.

Loading...

Loading...