214366 88 Revision A

1006681

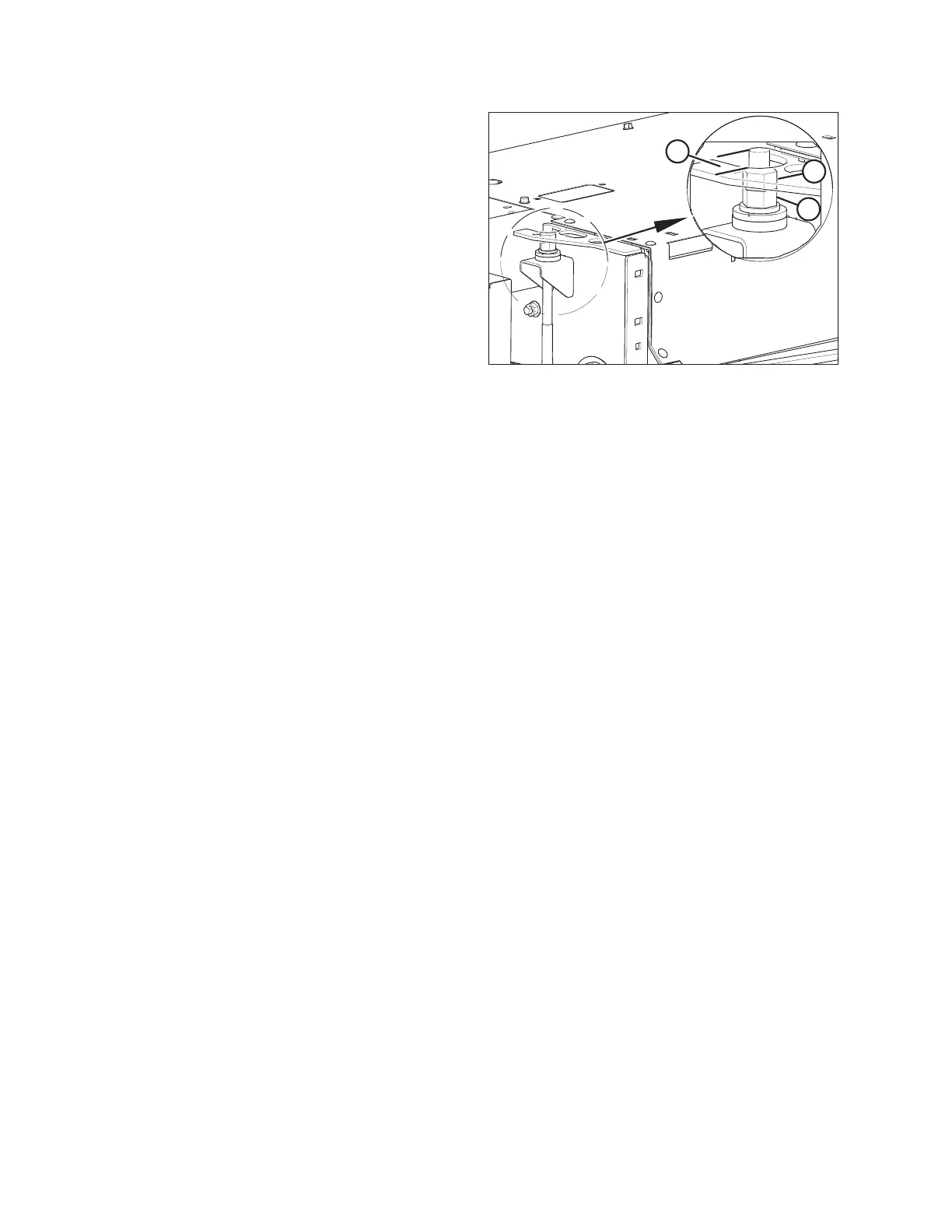

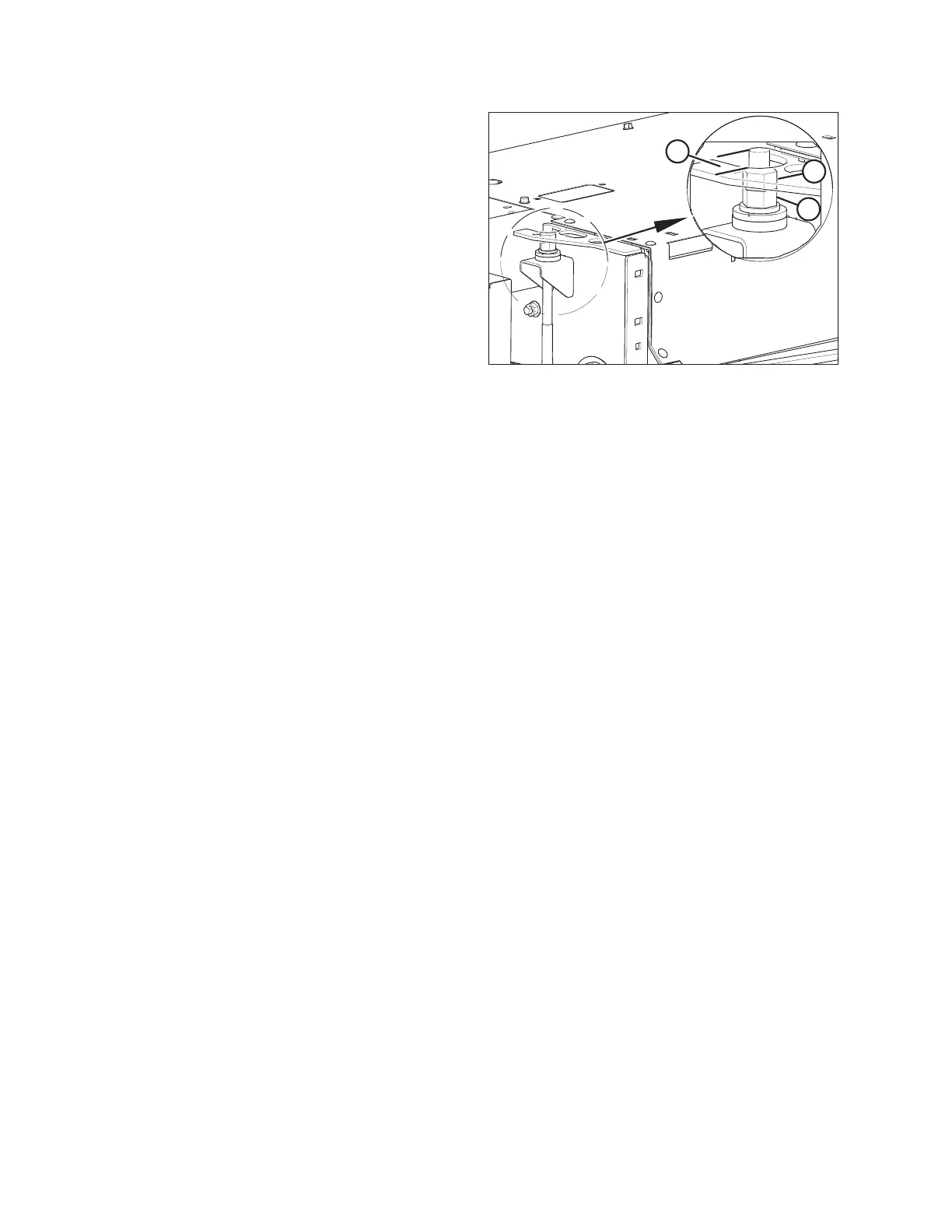

A

B

C

Figure 4.11: Roll Gap Adjustment Bolt

4. Loosen upper jam nut (B) on both sides of conditioner

adjustment bolts.

5. To increase roll gap, turn lower nut (A) clockwise.

6. To decrease roll gap, turn lower nut (A)

counterclockwise.

7. Measurement at (C) should be 35 mm (1.4 in.). This

equates to 25.4 mm (1 in.) of roll gap.

8. Once adjustment is complete, hold nut (A) and torque

jam nut (B) to 102 Nm (75 lbf·ft).

NOTE:

When adjusting roll gap, be sure that the thread

protruding at the adjustment is the same on both ends

of the conditioner rolls. This will achieve consistent

intermesh across the rolls.

9. Check roll gap. Refer to 4.2.1 Checking Roll Gap, page 86.

IMPORTANT:

Roll timing is critical when the roll gap is decreased because the bars may contact each other if the timing

is wrong.

10. Refer to 4.4 Roll Timing, page 90 for instructions on checking the timing.

11. Close the driveshield. Refer to 3.4 Driveshields, page 30.

OPERATING THE HEADER

Loading...

Loading...