214366 90 Revision A

4.4 Roll Timing

For proper conditioning, the rolls must be properly timed. Each steel bar on one of the rolls should be centered

between two bars of the other roll. The factory setting should be suitable for most crop conditions.

IMPORTANT:

Roll timing is especially critical when roll gap is decreased because the bars can contact each other if the timing

is wrong.

4.4.1 Checking Roll Timing

DANGER

To avoid bodily injury or death from unexpected startup of the machine, always stop the engine and

remove the key from the ignition before leaving the operator’s seat for any reason.

1006702

B

A

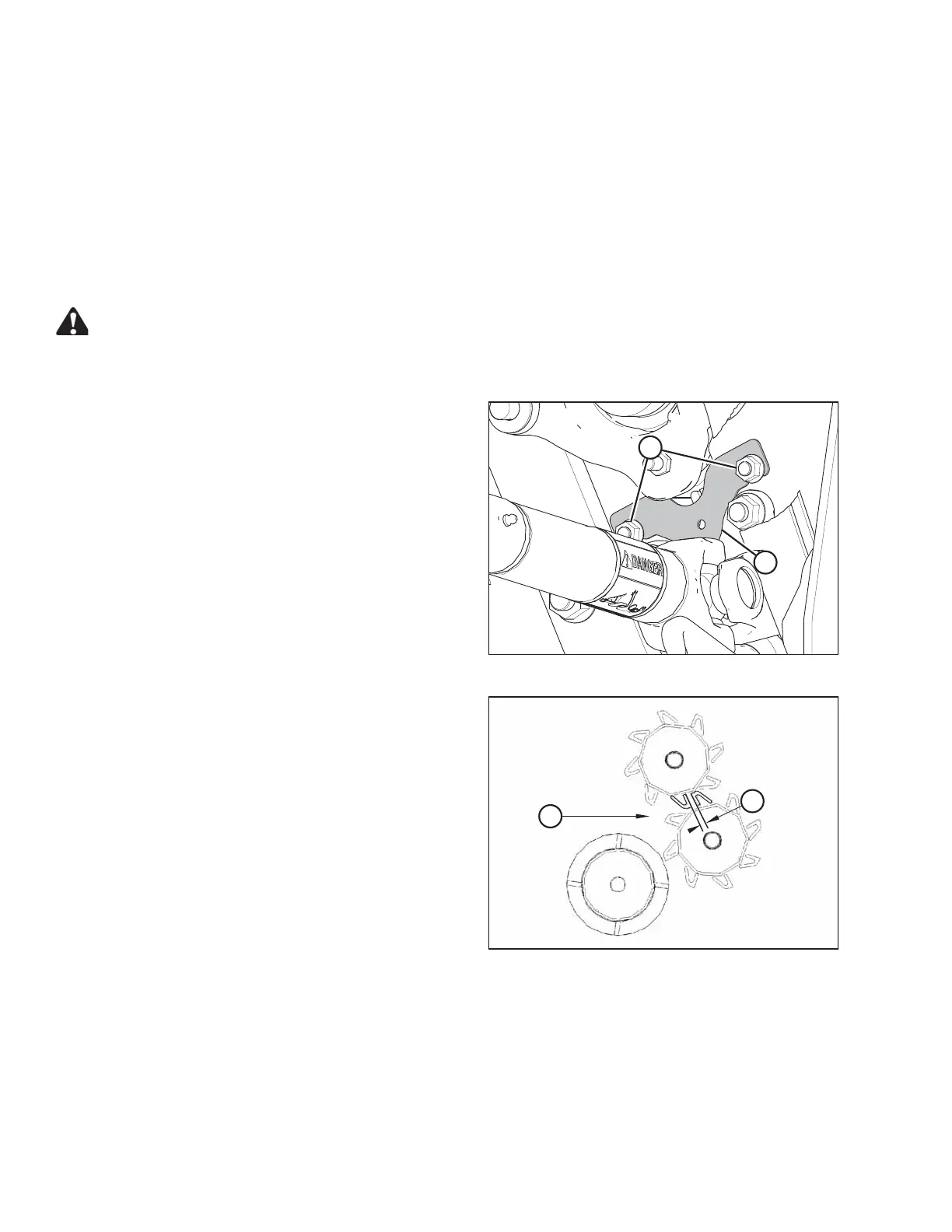

Figure 4.13: Conditioner Shield (Left Side)

1. Lower the header fully.

2. Stop engine and remove the key.

3. Open the driveshield. Refer to 3.4 Driveshields, page

30.

4. Loosen nuts (A) and slide conditioner shield (B) up to

remove it.

1002383

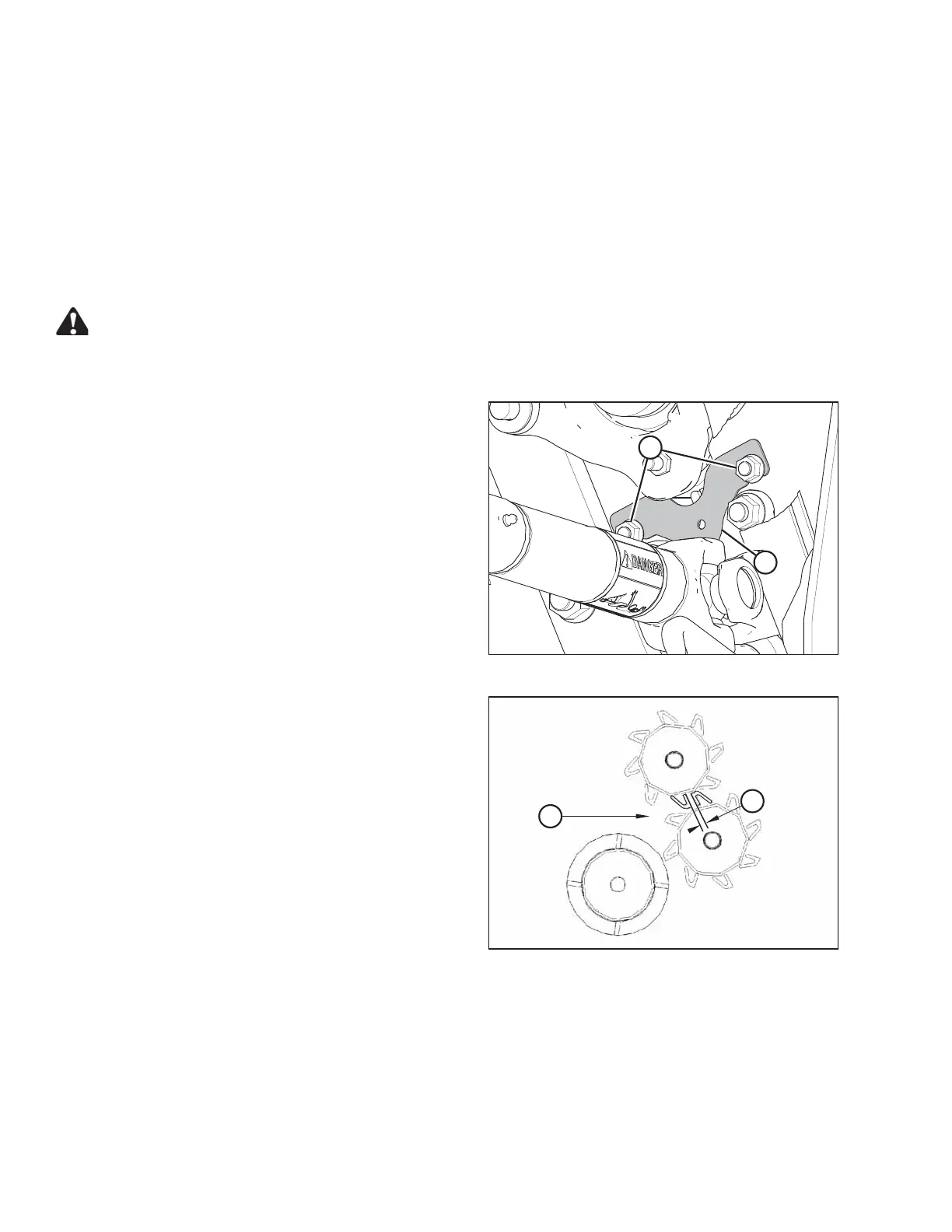

A

B

Figure 4.14: Roll Timing

A - Crop Flow

B - Roll Timing Distance 9–13 mm (0.35–0.51 in.)

5. Measure clearance (B) between the flats of the

conditioner roll bars at both end of the conditioner rolls.

Dimension (B) should be set to 9–13 mm

(0.35–0.51 in.). If adjustment is required, refer to 4.4.2

Adjusting Roll Timing, page 91.

NOTE:

There should be less than 2 mm (0.08 in.) difference

between the two ends of the conditioner roll.

NOTE:

Roll spacing not to scale in illustration.

6. Close the driveshield. Refer to 3.4 Driveshields, page 30.

OPERATING THE HEADER

Loading...

Loading...