214366 122 Revision A

5.2 Maintenance Requirements

In this manual, periodic maintenance requirements are organized by service intervals. For detailed instructions,

refer to the specific headings in this section.

Regular maintenance is the best insurance against early wear and breakdowns. Use the following schedule and

recommendations to increase machine life.

• Use fluids and lubricants specified on the inside back cover.

• Make copies of the 5.2.1 Maintenance Schedule/Record, page 122 and log the hours of operation.

Where a service interval is given with more than one timeframe, e.g., 100 hours or Annually, service the machine at

whichever interval is reached first.

IMPORTANT:

Recommended intervals are for average conditions. Service the machine more often if operated under adverse

conditions (severe dust, extra heavy loads, etc.).

CAUTION

Carefully follow safety messages given in 1 Safety, page 1.

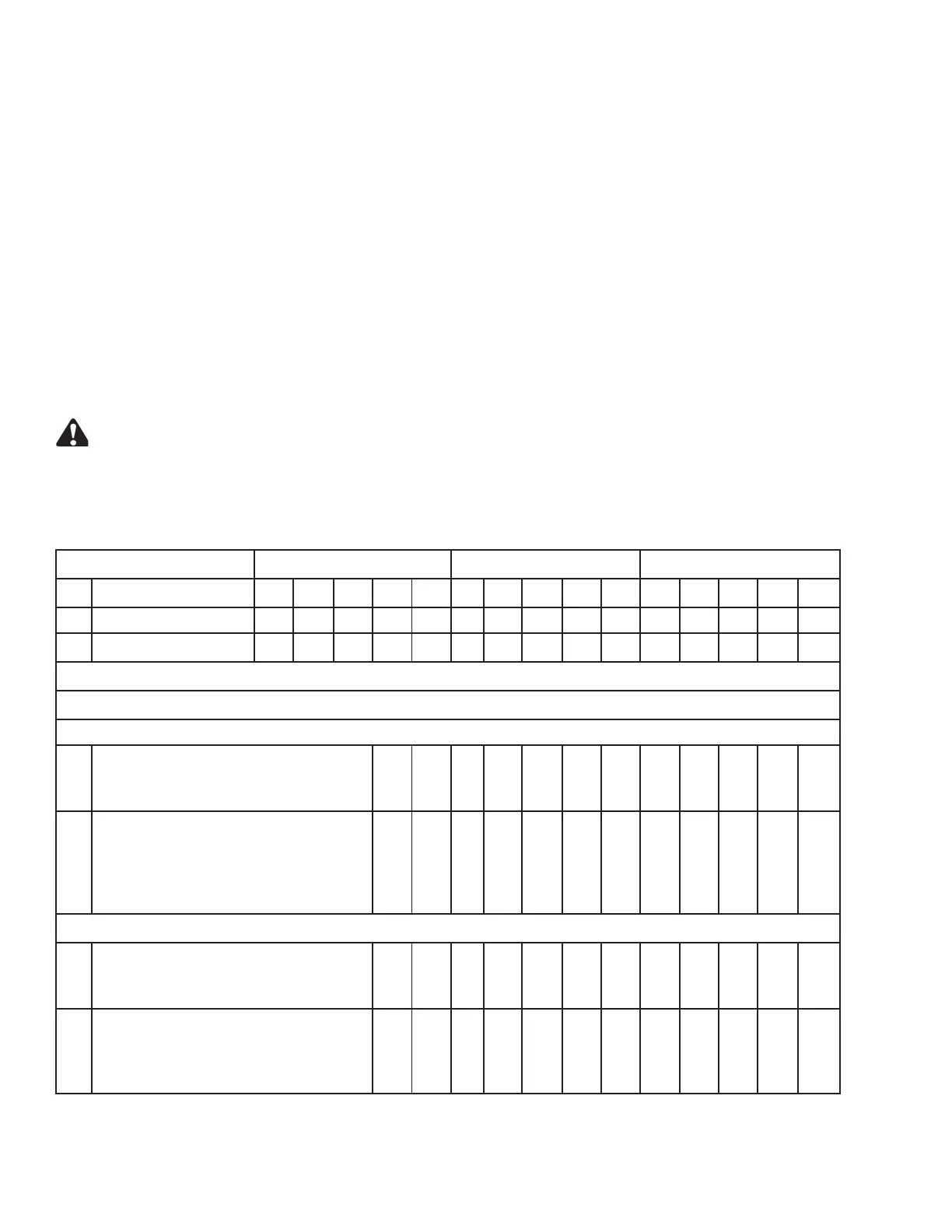

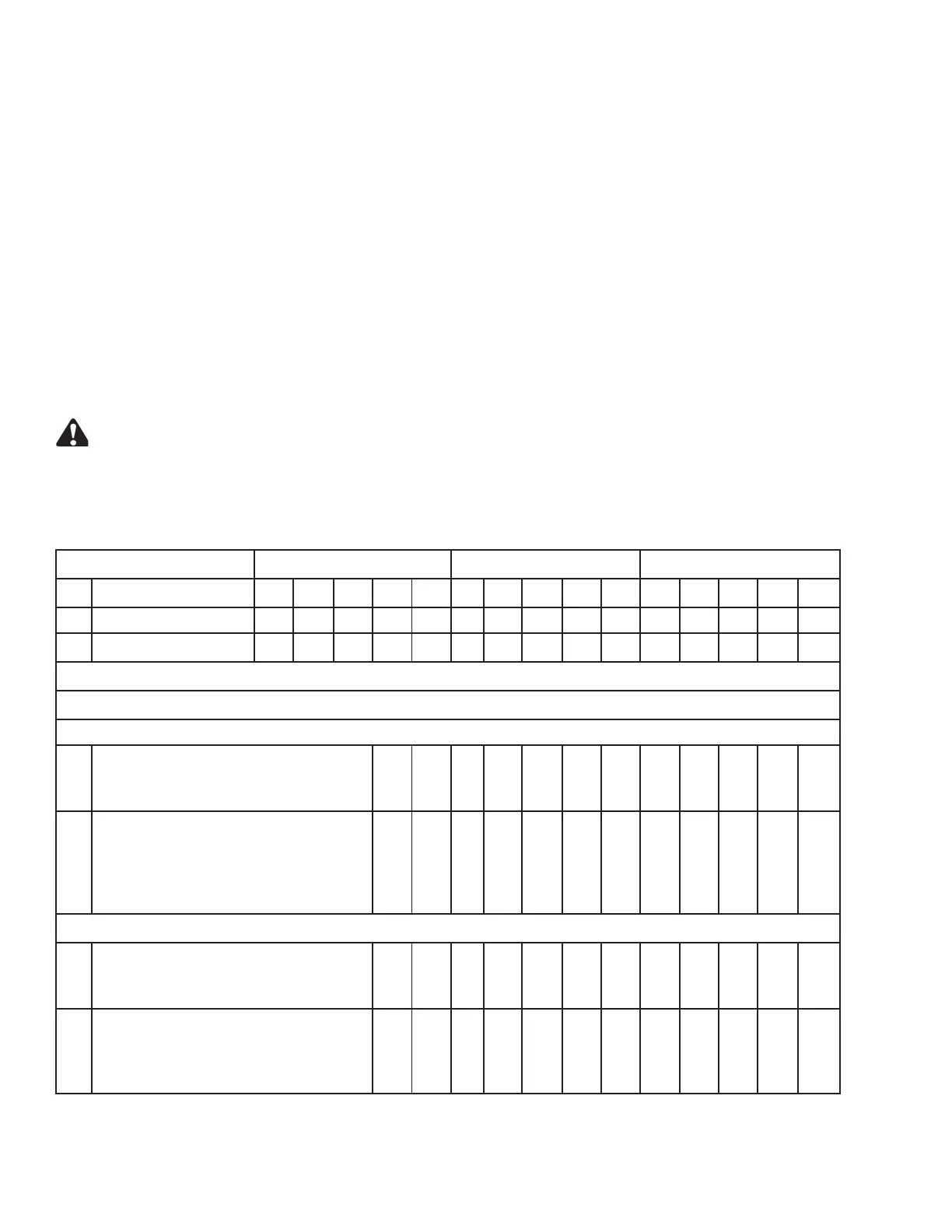

5.2.1 Maintenance Schedule/Record

Action üü Check SS Lubricate ▲ Change

!

Hour meter reading

!

Service date

!

Serviced by

Preseason or Annual. Refer to 5.2.2 Preseason/Annual Service, page 125.

End of season. Refer to 5.2.3 End-of-Season Service, page 125.

First 5 hours

ü

Check for loose hardware.

Refer to 8.1 Torque Specifications,

page 185.

ü

Check drive belt tension.

Refer to Inspecting the Conditioner

Drive Belt, page 159 and Inspecting

and Adjusting the Auger Drive Belts,

page 166.

First 10 hours then daily

ü

Check hydraulic hoses and lines.

Refer to 5.5.2 Hydraulic Hoses and

Lines, page 172.

ü

Check cutterblades, deflectors, and

discs.

Refer to 5.3.2 Inspecting the Cutterbar

Discs, page 138.

MAINTENANCE AND SERVICING

Loading...

Loading...