214366 81 Revision A

4 Operating the Header

Your header will provide the best performance when it is properly adjusted to suit the crop and conditions.

Correct operation reduces crop loss and increases productivity. As well, proper adjustments and timely

maintenance will increase the length of service you receive from the machine.

The variables listed below and detailed on the following pages will affect the performance of the header. You will

quickly become familiar with adjusting the machine to give you the desired results. Most of the adjustments have

been set at the factory, but if desired, the settings can be changed to suit crop conditions.

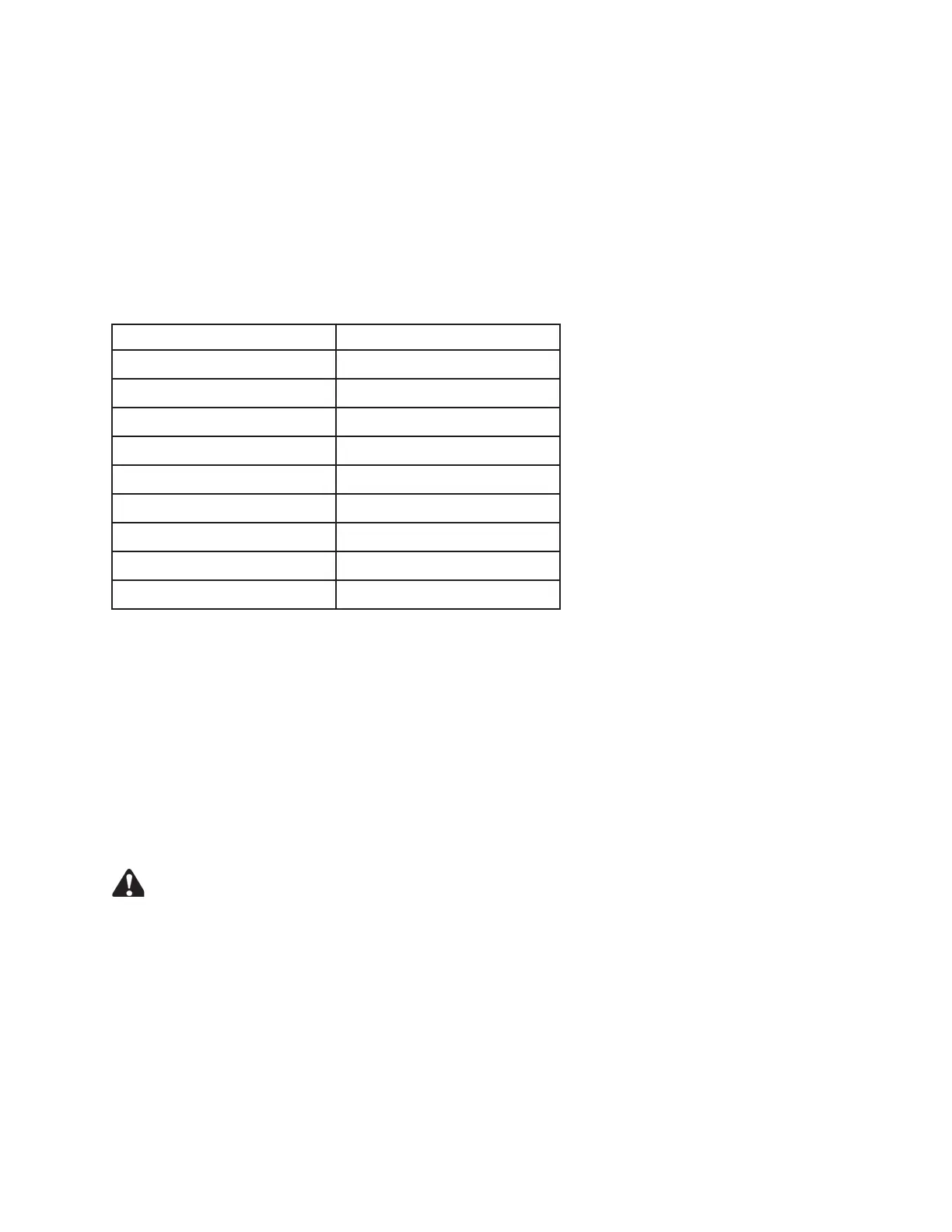

Table 4.1 Header Adjustment Procedures

Variable

Refer to

Header float

4.1 Header Float, page 81

Roll gap

4.2 Roll Gap, page 86

Roll tension 4.3 Roll Tension, page 89

Roll timing

4.4 Roll Timing, page 90

Forming shields

4.5 Forming Shields, page 93

Header angle 4.6 Header Angle, page 97

Cutting height 4.7 Cutting Height, page 98

Disc speed

4.8 Disc Speed, page 100

Ground speed 4.9 Ground Speed, page 101

4.1 Header Float

Header float springs are normally set so 426–471 N (95–105 lbf) is required to lift the header at either end.

In rough or stony conditions, it may be desirable to maintain a lighter setting to protect cutting components.

When float setting is light, it may be necessary to use a slower ground speed to avoid excessive bouncing resulting

in a ragged cut. Faster ground speeds may require additional ground pressure.

Up to three user-defined float positions can be stored in the windrower's control system. For information on setting

float, refer to the Float Options topic in the windrower operator's manual.

4.1.1 Checking Float – M200 and M205 Windrowers

DANGER

To avoid bodily injury or death from unexpected startup of the machine, always stop the engine and

remove the key from the ignition before leaving the operator’s seat for any reason.

Set the float fine adjustment to MID-RANGE with the windrower float adjustment system in the cab (refer to your

windrower operator’s manual).

1. Lower the header until lift cylinders are fully retracted.

2. Stop the engine and remove the key.

3. Grasp the front corner of the header and lift. The force required to lift the header should be 426–471 N (95–105

lbf) and should be approximately the same at both ends. If adjustment is required, refer to 4.1.2 Adjusting Float

Loading...

Loading...