214366 89 Revision A

4.3 Roll Tension

Roll tension (the force holding the rolls together) is factory set with a spring-type adjustable linkage.

The roll tension factory setting is the spring fully tensioned.

Heavy crops or tough forage tend to separate the rolls and require more tension to ensure material is sufficiently

crimped. Light alfalfa and short grasses require less tension to minimize over-conditioning.

4.3.1 Adjusting Roll Tension

DANGER

To avoid bodily injury or death from unexpected startup of the machine, always stop the engine and

remove the key from the ignition before leaving the operator’s seat for any reason.

Before changing the factory adjusted roll tension, refer to 4.2.2 Adjusting Roll Gap, page 87 to ensure the roll gap

setting is ideal for your crop type.

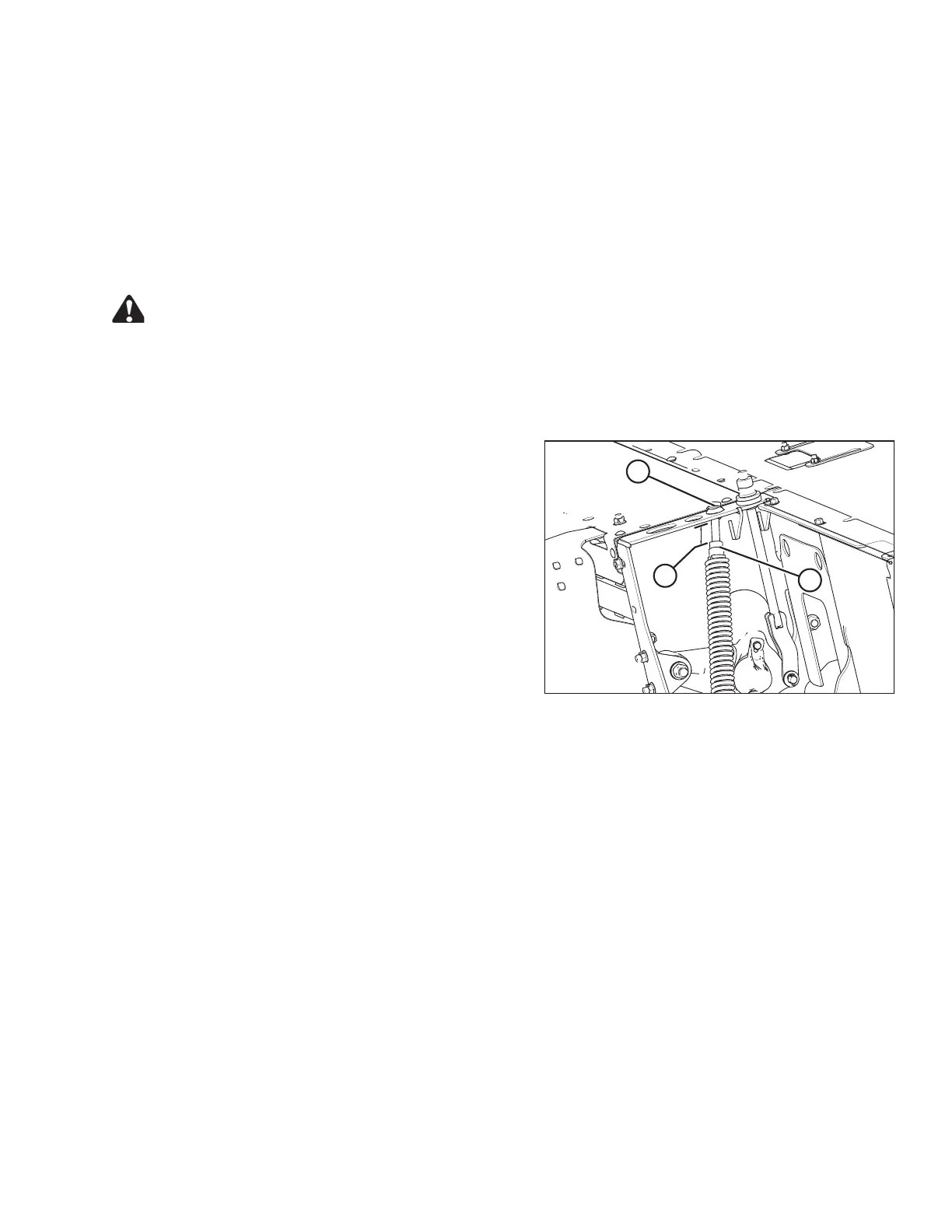

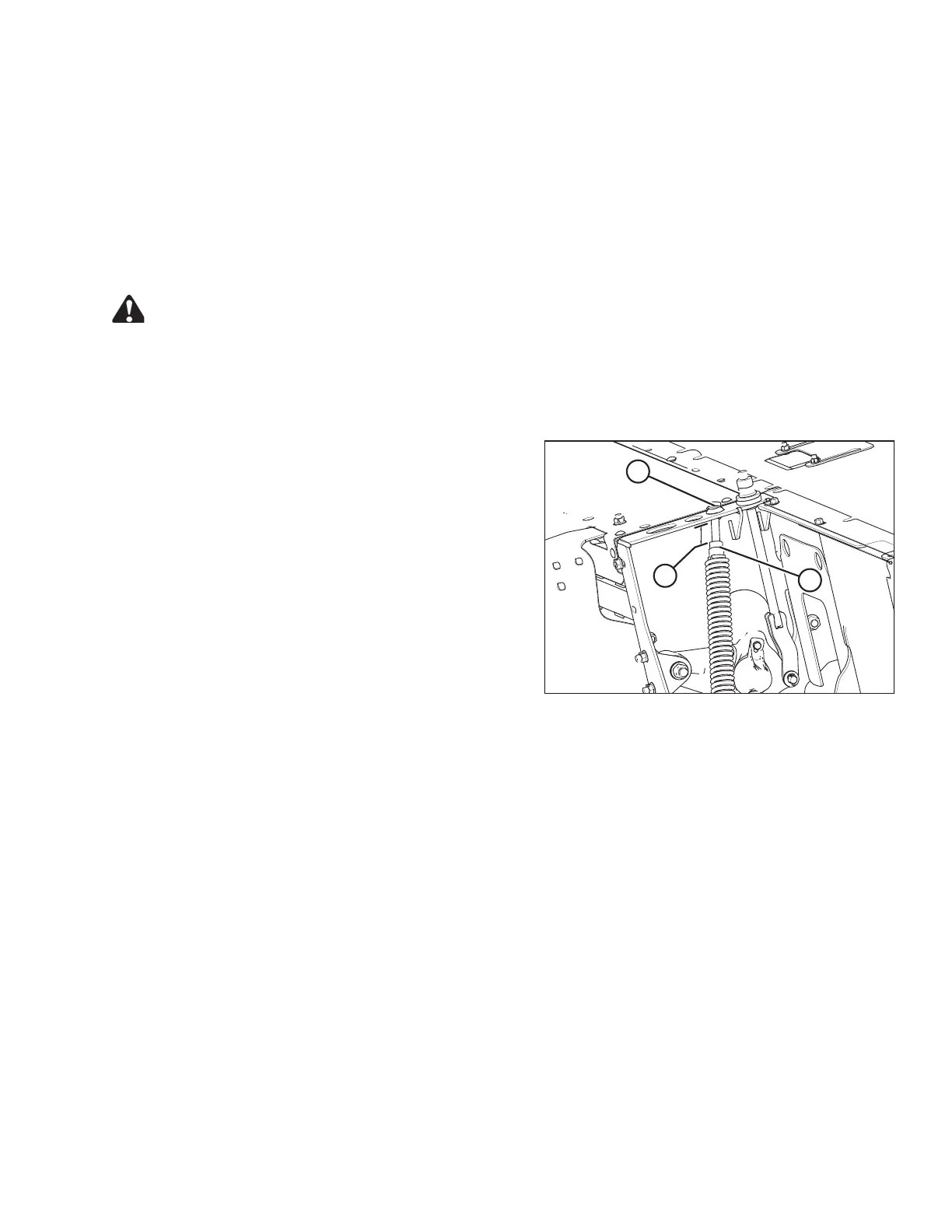

1002387

A

B

C

Figure 4.12: Roll Tension Spring (Right Side)

1. Lower the header fully.

2. Stop the engine and the remove the key.

3. Open the driveshield. Refer to 3.4 Driveshields, page

30.

4. To decrease the roll tension, turn the spring drawbolts

counterclockwise to loosen the springs. Set

dimension (C) to 45–55 mm (1.77–2.16 in.).

5. To increase the roll tension, loosen jam nut (A) and turn

spring drawbolt (B) clockwise to tighten the spring at

each end of the roll. Set dimension (C) to 45–55 mm

(1.77–2.16 in.).

IMPORTANT:

Turn each bolt equal amounts. Each turn of the bolt

changes the roll tension by approximately 44.5 N

(10 lbf).

6. Tighten jam nut (A) against casting after adjusting

tension.

7. Close the driveshield. Refer to 3.4 Driveshields, page

30.

OPERATING THE HEADER

Loading...

Loading...