12 - 5

Care and maintenance

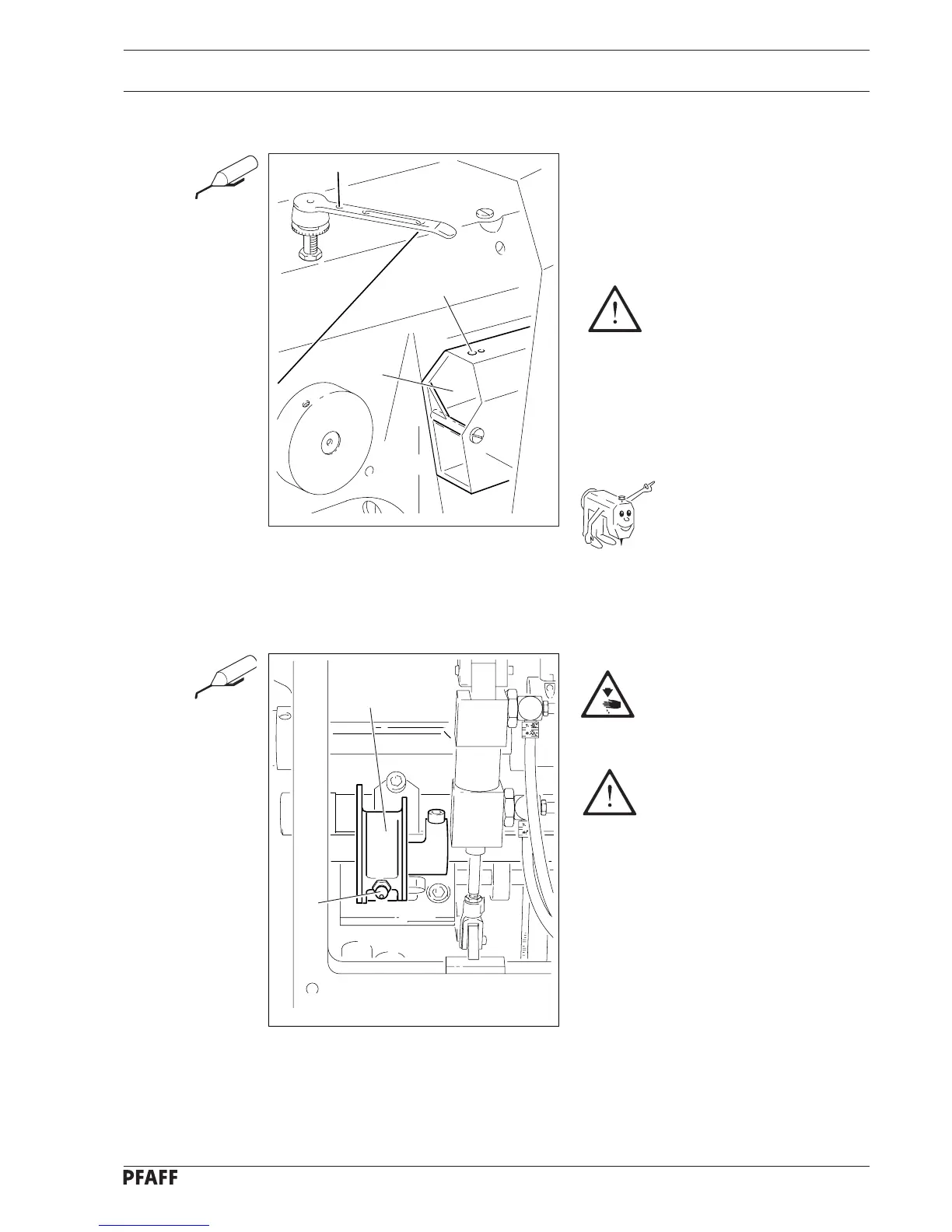

12.07 Lubricating the needle bar frame eccentric

Switch off the machine and

ensure that it cannot be

switched on accidentally!

Turn off compressed air!

Only use Isoflex Topas L32,

high-performance grease, part

No. 280-1-120 210.

● Unscrew the cover on the reverse side

of the sewing head.

● Grease eccentric 1 via grease nipple 2

using a grease gun every 2 months for

single-shift operation and monthly for

double-shift operation.

● Screw on cover.

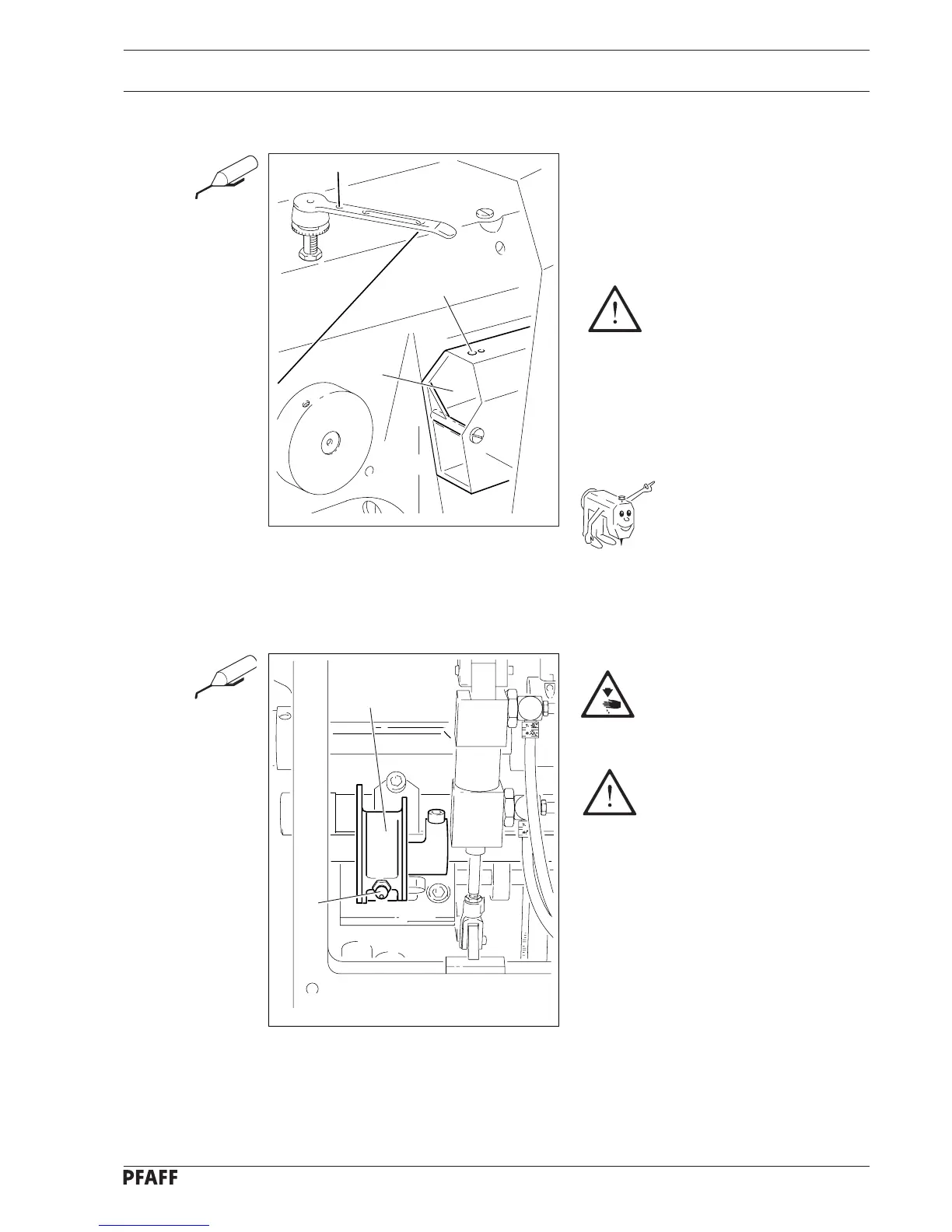

12.06 Checking the oil level of the sewing head lubrication

● The oil level in drum 1 must be checked

daily before use of the machine.

● The oil level must be between the upper

and lower markings of drum 1.

● When necessary, pour oil through hole 2.

Only use oil with a mean

viscosity of 22.0 mm

2

/s at 40°C

and a density of 0.865 g/cm

3

at

15°C.

● Before the machine is first operated or

whenever the machine has been at a

standstill for a longer period of time, also

add a few drops of oil to the hook race.

We recommend PFAFF

sewing machine oil,

part no. 280-1-120 144.

Fig. 12 - 06

Fig. 12 - 07

2

1

1

2

Loading...

Loading...