Chapter E - C-ARM AND IMAGING ARM

Planmeca ProMax E-67

PROMAX 3D: ADJUSTMENTS & CALIBRATIONS

Technical Manual

Darken the room sufficiently so that you will be able to see the image of the radiation beam on

the alignment tool (it is fluorescent and will glow when the radiation beam strikes it), but not so

dark that you cannot see the lines of the alignment rectangle.

Protect yourself from radiation and press the exposure button. The beam image appears on

the alignment tool. Observe the beam from behind the tube head.

CAUTION Radiation is generated when the exposure button is pressed. Take

adequate protection measures. Keep the exposure time as short as

possible.

X-ray units with 3D sensor V1:

The radiation beam must reach but not overlap the lines marked on the left and right of

the beam alignment tool (shown with arrows in Fig. 86).

X-ray units with 3D sensor V2:

Use the lines marked on the left and right of the beam alignment tool as reference lines

(shown with arrows in Fig. 86). The radiation beam must be 4 mm wider on both sides

(total 8 mm wider).

X-ray units with 3D s sensor:

Use the lines marked on the left and right of the beam alignment tool as reference lines

(shown with arrows in Fig. 86). The radiation beam must be 20 mm narrower on both sides

(total 40 mm narrower).

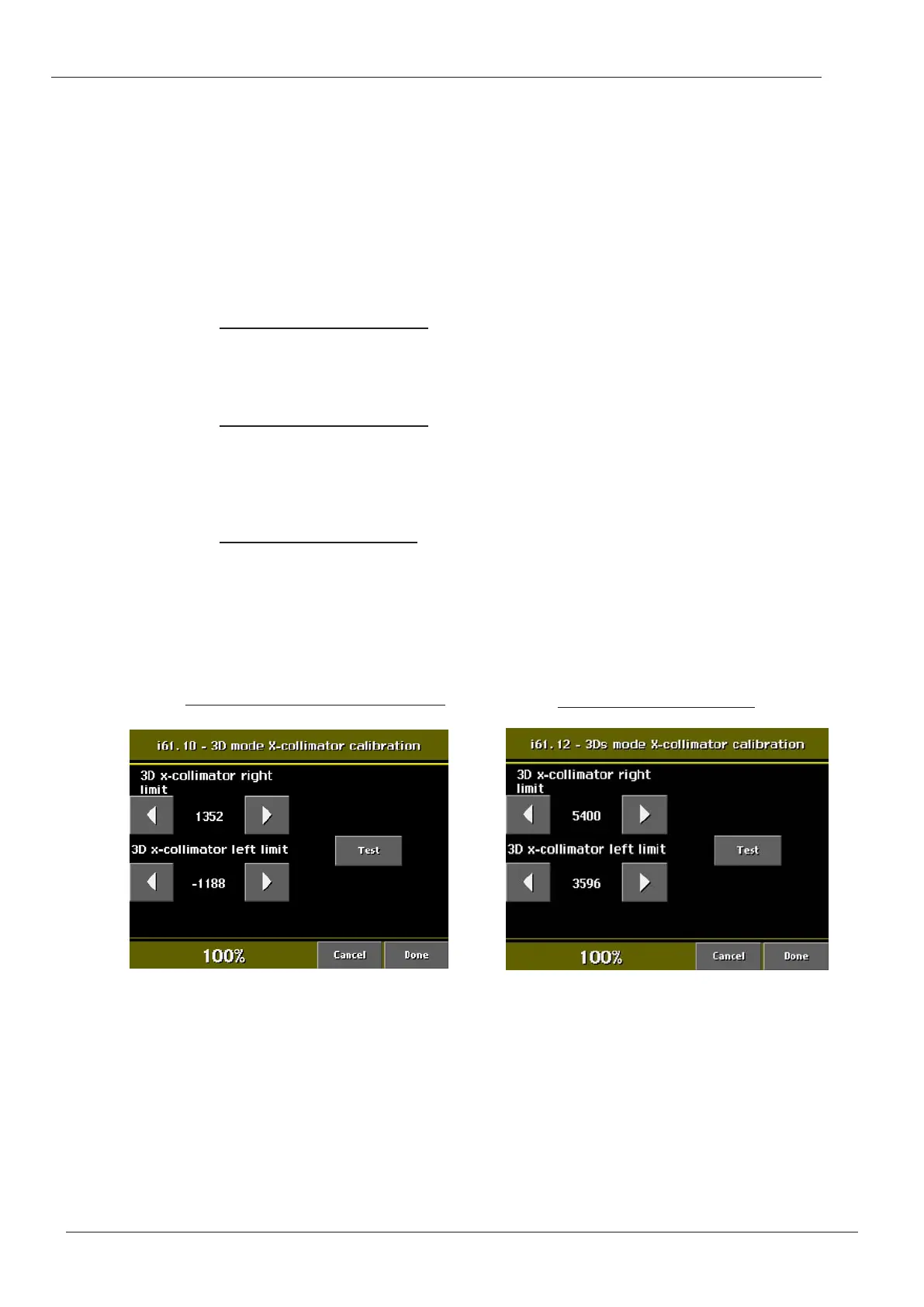

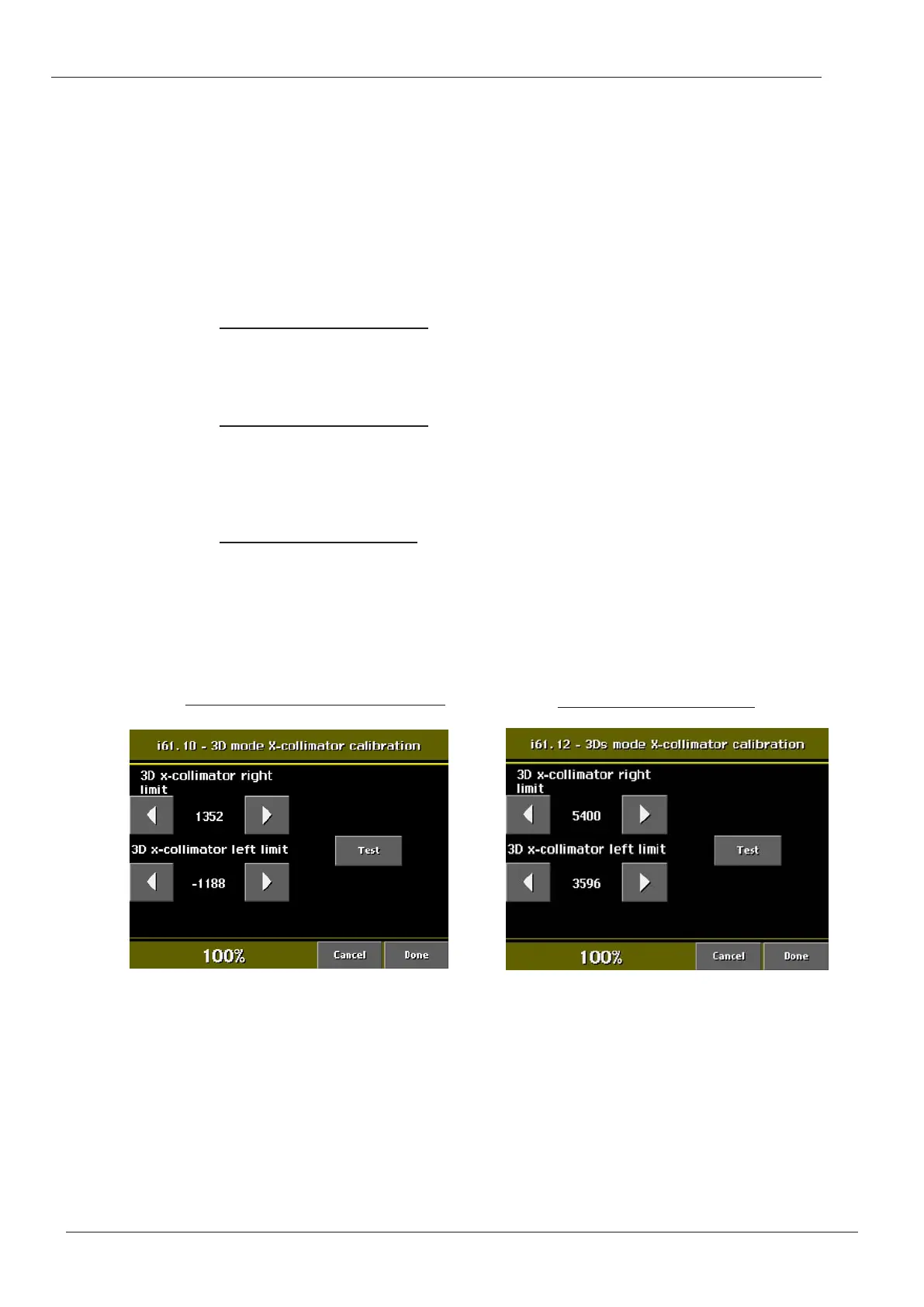

The X-ray beam horizontal position is adjusted on the X-collimator calibration (i61.10 or

i61.12) display.

Figure 87

Adjust the collimator position value with the x-collimator right and left limit arrow fields. The

left arrow field on the display adjusts the beam to the left, and the right arrow field to the right.

Drive the collimator to the selected position by touching the Test field.

Protect yourself from radiation and press the exposure button to check the position of the

beam. If necessary, repeat the procedure.

Accept the new position and exit the calibration mode by touching the Done field. The values

are not stored if you exit the mode with Cancel field.

X-ray units with 3D s sensor:

X-ray units with 3D sensor (V1 or V2):

Loading...

Loading...