Section04ENGINEMANAGEMENT(15034-TEC)

Subsection 03 (COMPONENT INSPECTION, REPLACEMENT AND ADJUSTMENT)

Connect one test probe to the WHITE/GREY wire

and the other test probe to the switch top ter-

minal. Measure resistance, it must be close to

0ohm.

Connect one test probe to the BLACK wire and

the other test probe to the switch ring. Measure

resistance, it must be close to 0 ohm.

Safety Lanyard on Switch

Connect test probes to switch BLACK and

BLACK/YELLOW wires. Measure resistance,

it must be close to 0 ohm.

ECM AND MPEM

General

Prior to replacing a suspected ECM or MPEM, en-

sure that all the recommendations in the general

introduction of this section have been followed.

IMPORTANT: When the ECM is replaced, the

Closed Throttle and Idle Actuator must be re-

set. Refer to its specific section for adjustment.

To allow transferring the previous recorded infor-

mation from the old ECM or MPEM to the new

one, use the vehicle communication kit (VCK)

with the B.U.D.S. software. Use Replace ECM

or MPEM in the Module menu. Follows instruc-

tions in its help system.

NOTE: If the old ECM or MPEM is working, it

must be read inside B.U.D.S. prior to removing it

from the vehicle to carry vehicle information and

history to the new ECM or MPEM. Otherwise, per-

form the operations described in IF THE PREVI-

OUS MPEM WAS NOT READ with B.U.D.S. be-

low.

ECM Replacement

CAUTION: Never try to use a 4-TEC Super-

charged ECM on a naturally-aspirated engine.

Doing so will automatically lead to a misfunc-

tion of the Engine Management System (EMS)

and will cause irregular combustion which

will damage the engine. Always make sure to

replace the ECM by an appropriate unit.

Disconnect battery cables.

WARNING

Battery BLACK negative cable must always be

disconnected first and connected last.

Disconnect both ECM connectors from ECM.

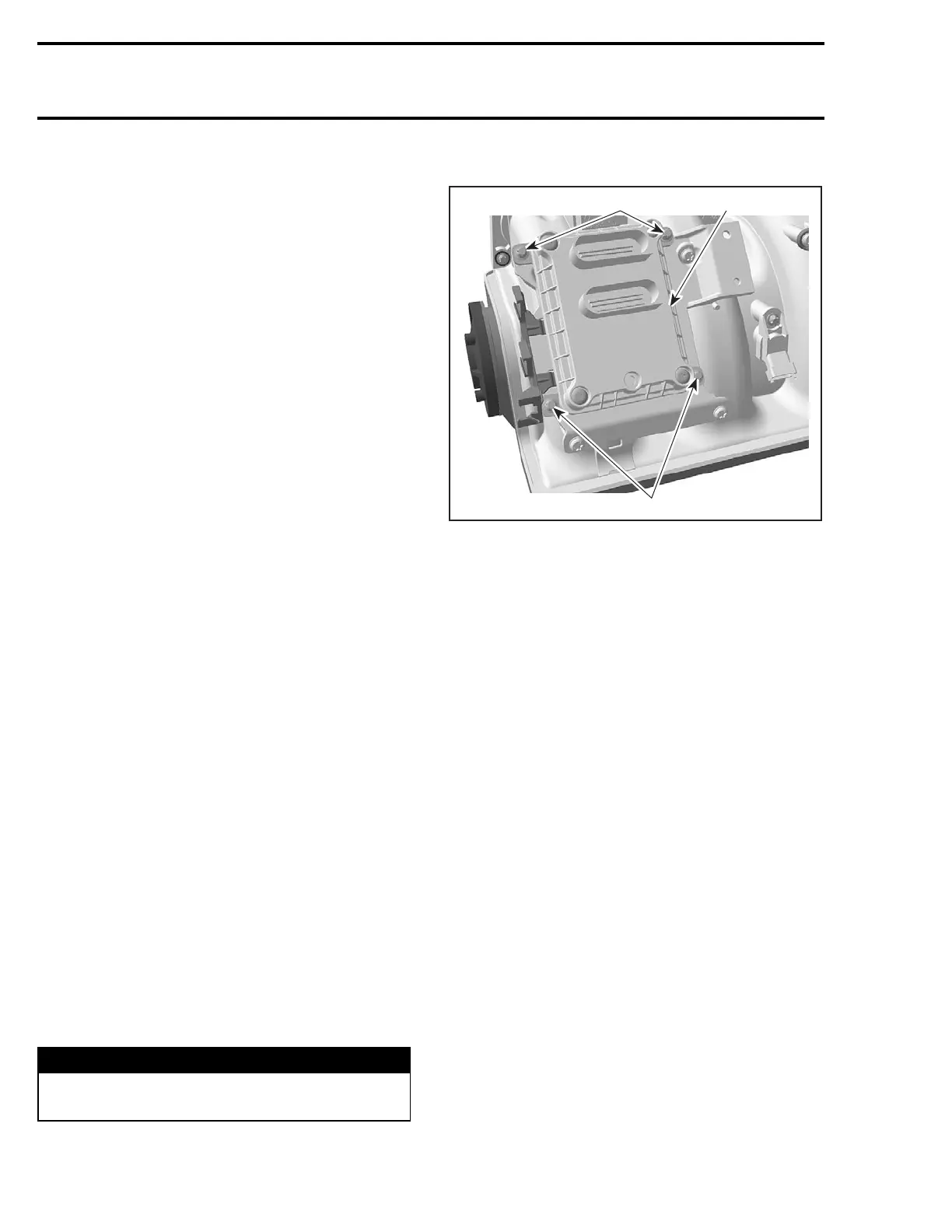

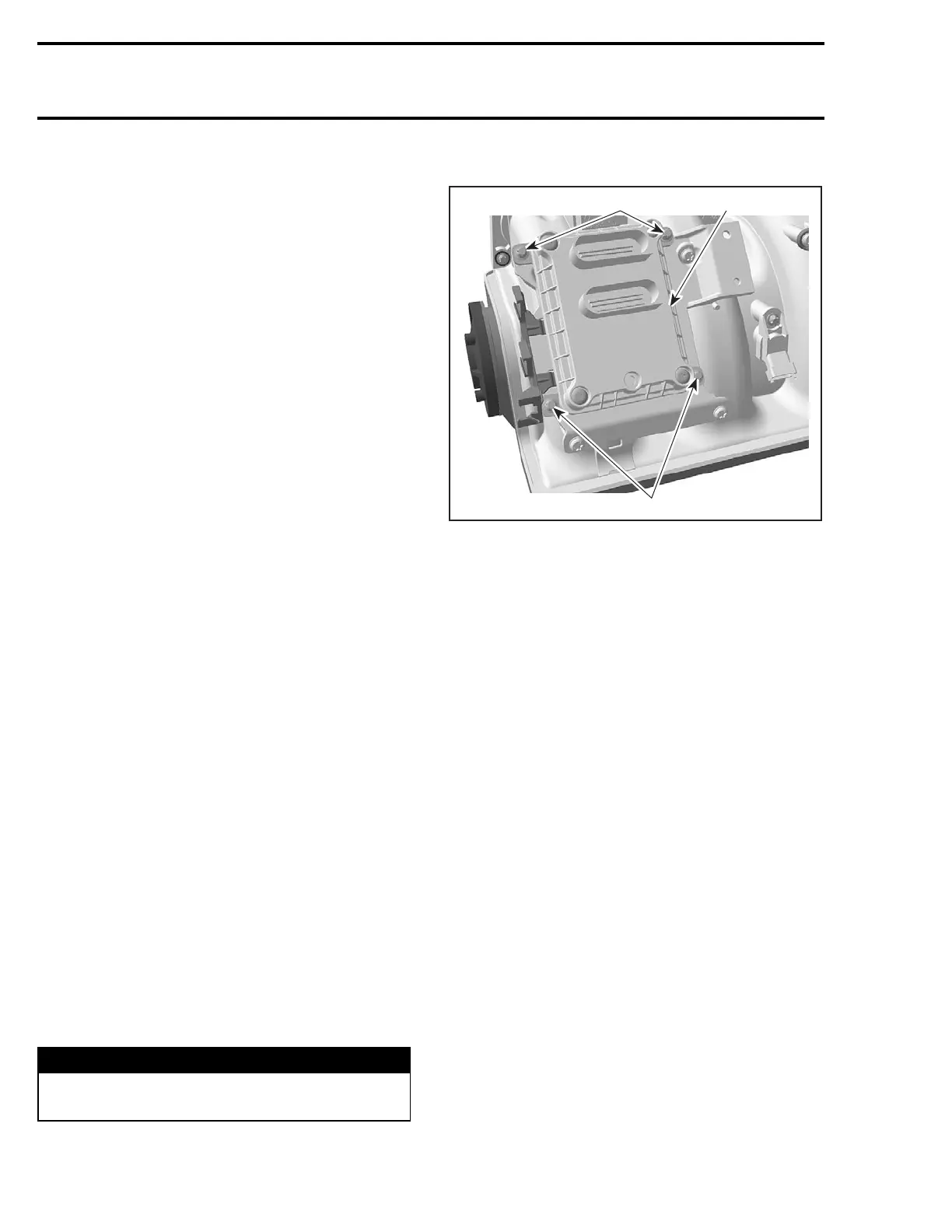

2

2

R1503motr180A

1

TYPICAL

1. ECM

2. Retaining screws

Unscrew all retaining screws and remove the en-

gine ECM from intake manifold.

CAUTION: If ever ECM is replaced, replace it by

the same part or by an approved equivalent.

Install the new ECM to the engine.

Reconnect ECM connectors to ECM then battery

cables.

If the previous ECM was read with B.U.D.S.

Transfer the data from the previous ECM to the

new one using B.U.D.S. then proceed with the

required resets.

Continue procedure as per FINALIZING ECM RE-

PLACEMENT below.

If the previous ECM was NOT read

with B.U.D.S.

– Enter the old ECM serial number in the Part

Replacement under History tab. Click on Add

part in History.

– Reprogram safety lanyard(s).

NOTE: The ECM serial number can be found on

the ECM sticker that also shows the P/N.

Continue procedure as per FINALIZING ECM RE-

PLACEMENT below.

112 smr2005-013

Loading...

Loading...