Section01MAINTENANCE

Subsection 01 (MAINTENANCE CHART)

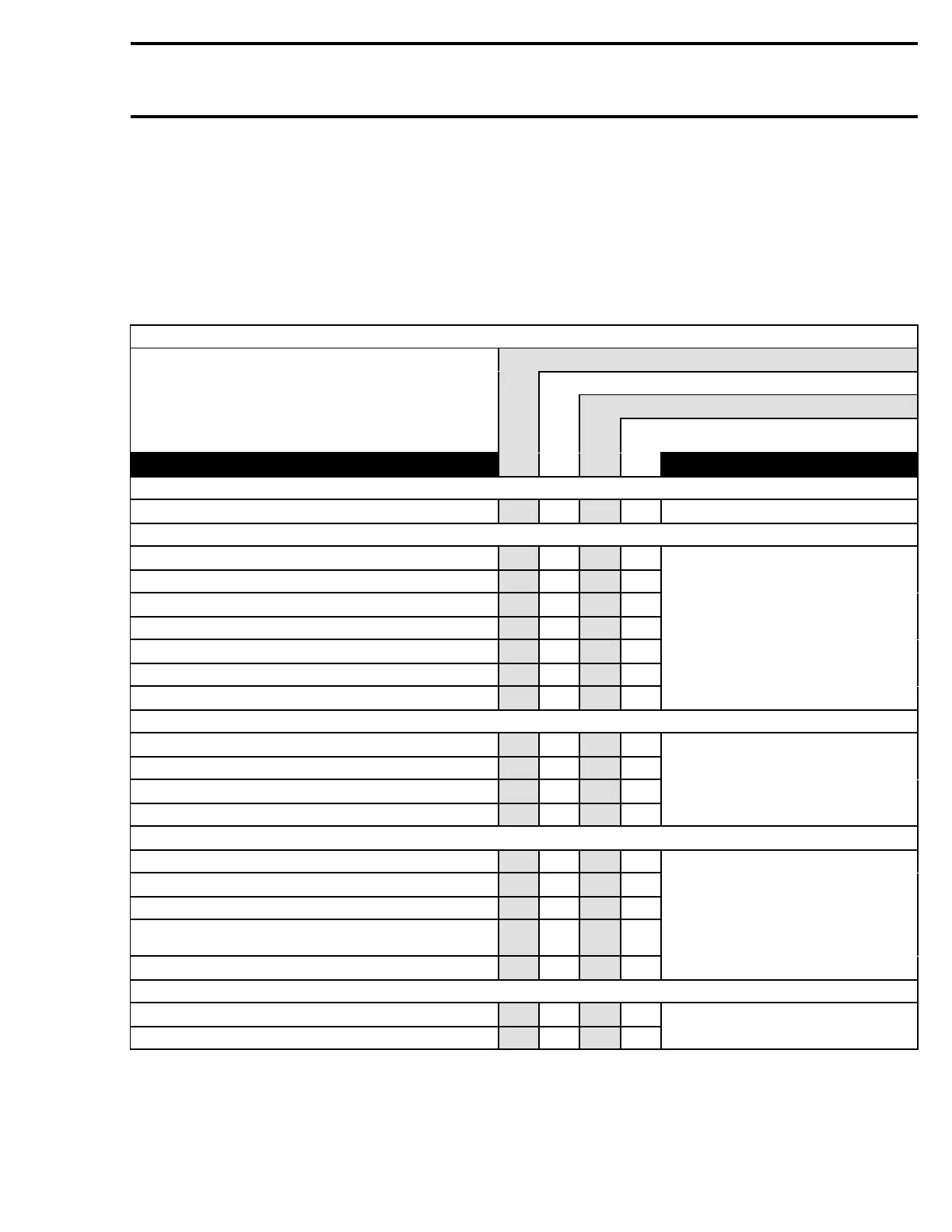

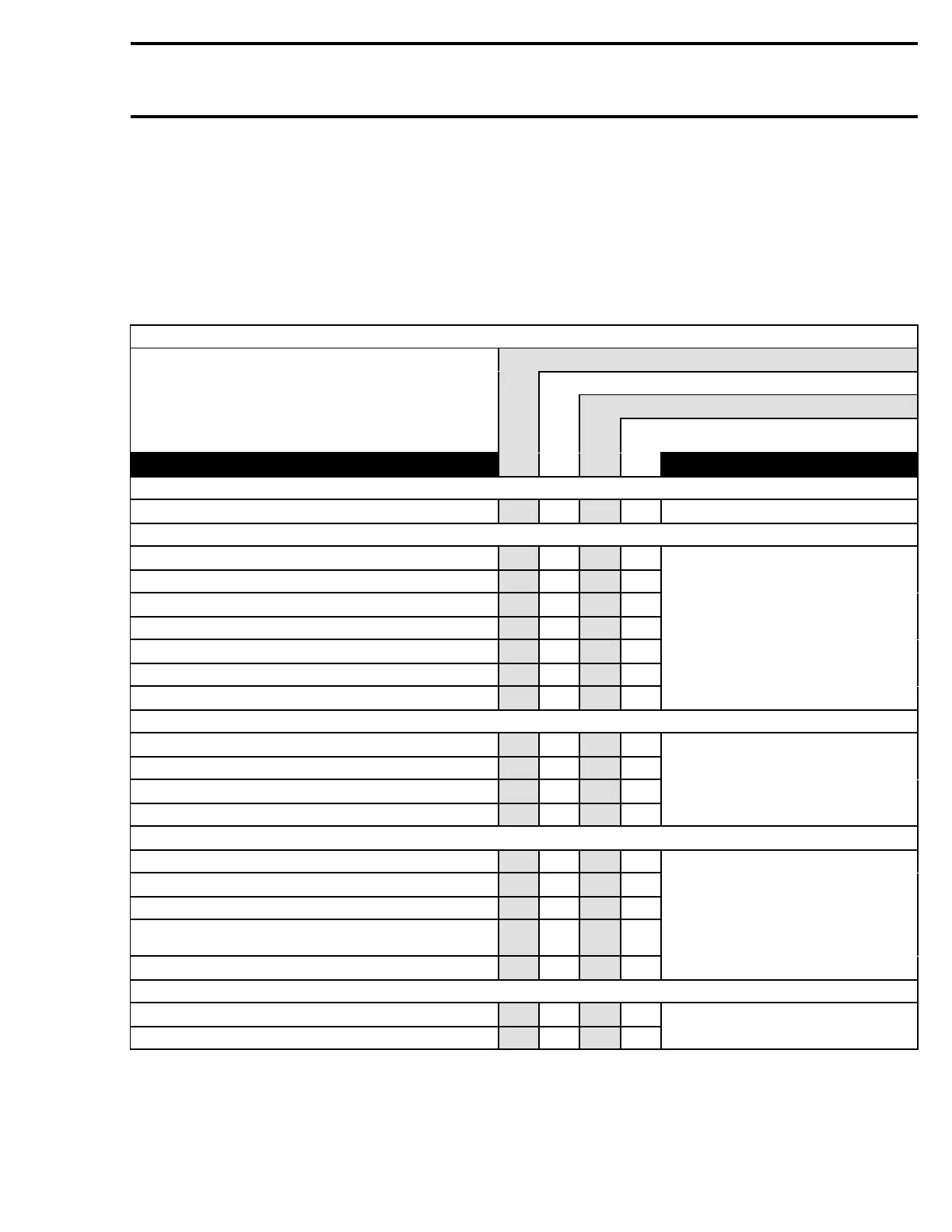

MAINTENANCE CHART

The schedule should be adjusted according to operating conditions and use.

NOTE: The chart gives an equivalence between number of hours and months/year. Perform the mainte-

nance operation to whatever time comes first.

IMPORTANT: Watercraft rental operations or intensive use of watercraft, will require greater frequency

of inspection and maintenance.

4-TEC MODELS

FIRST 10 HOURS

EVERY25HOURSOR3MONTHS

EVERY 50 HOURS OR 6 MONTHS

A: ADJUST

C: CLEAN

I: INSPECT

L: LUBRICATE

R: REPLACE

T: PROCEED WITH TASK

EVERY 100 HOURS OR 1 YEAR

PART/TASK LEGEND

GENERAL

Lubrication/corrosion protection T

ENGINE

Engine oil and filter (including cover's O-rings) R R(7)

Support and rubber mount I I

Seals and fasteners I I

Exhaust system fasteners (5) I I

Spark plug (5) R

Supercharger slipping moment (if so equipped) I

Supercharger drive gear, shaft and lock washer (if so equipped) I (10)

(5) Emission-related component.

(7) Replace for storage period or after 100 hours

of use whichever comes first.

(10) Every 100 hours of use for supercharged

engines.

Every 200 hours of use for supercharged

intercooled engines.

COOLING SYSTEM

Flushing (exhaust system) T(3)

Hose and fasteners I I

Coolant I R(7)

Coolant expansion tank cap/cooling system pressure test T(4)

(3) Daily flushing in salt water or foul water use.

(4) Perform every 200 hours or 2 years.

(7) Replace for storage period or after 100 hours

of use whichever comes first.

FUEL SYSTEM

Throttle cable I, A, L

Engine management system sensors I I

Fault code reading of engine management system (1) (5) I

Fuel lines, fuel rail, connections, pressure relief valve and fuel system

pressurization (5)

I I

Fuel tank straps I I

(1)Insaltwateruse.

(5) Emission-related component.

AIR INTAKE SYSTEM

Throttle body (5) I I,L

Air intake silencer fit/tightness I I

(5) Emission-related component.

smr2005-003 1

Loading...

Loading...