Section05FUELSYSTEM

Subsection 01 (FUEL TANK AND FUEL PUMP)

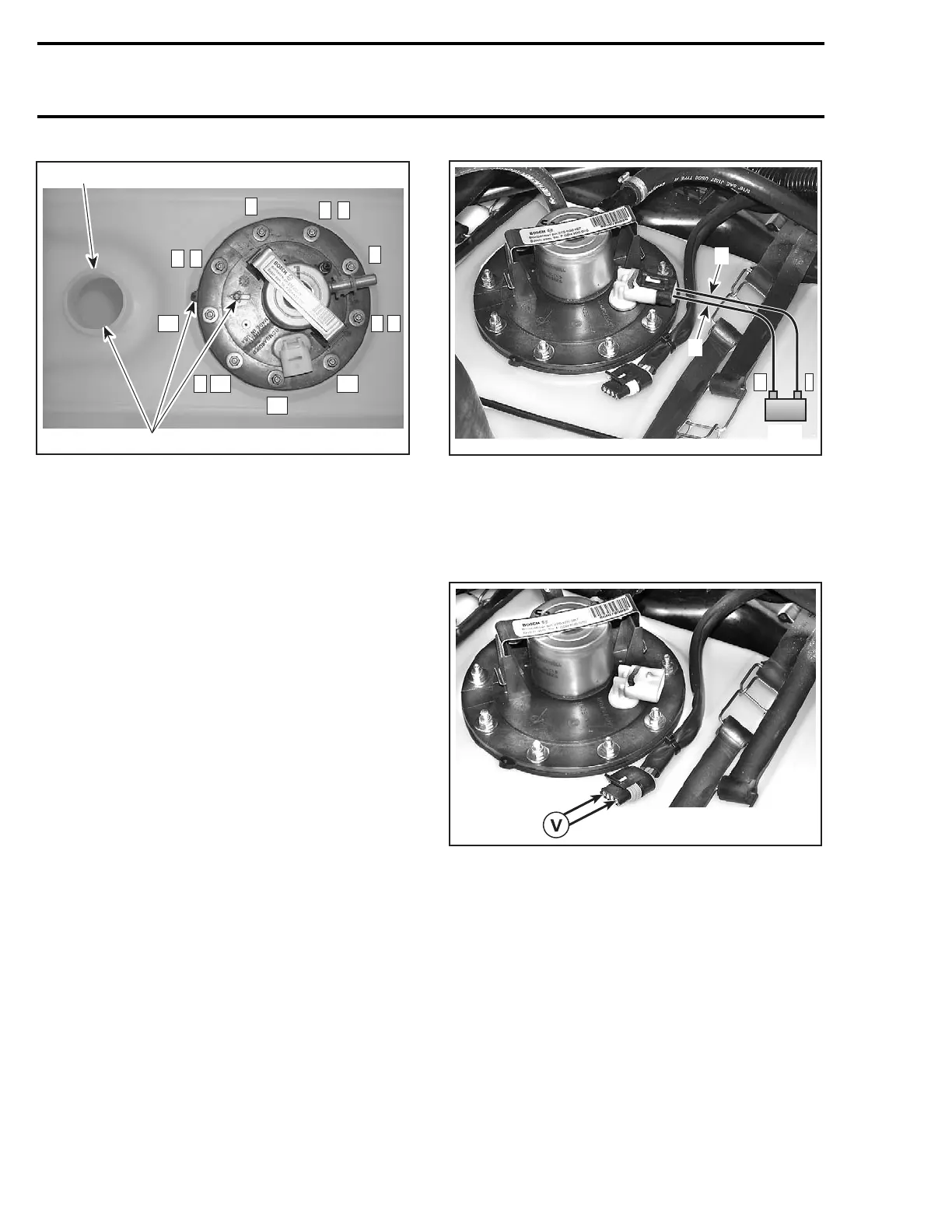

1

F18R0AA

1 5

6

3 7

8

2 9

10

11

13

12

2

4

TIGHTENING SEQUENCE

1. Fuel tank neck

2. Align

Perform a pressure test on fuel tank. Refer to FU-

EL TANK PRESSURE TEST.

Fuel Tank

Ensure rubber carpets no. 19 are in place.

Insert tank, air box and straps.

Place straps in clips (bottom) and in guides of air

box. Use tape to hold straps on the top of fuel

tank.

Insert strap ends in hooks.

Properly secure harnesses.

Reinstall all other removed parts. Refer to the ap-

propriate section.

TESTING PROCEDURES

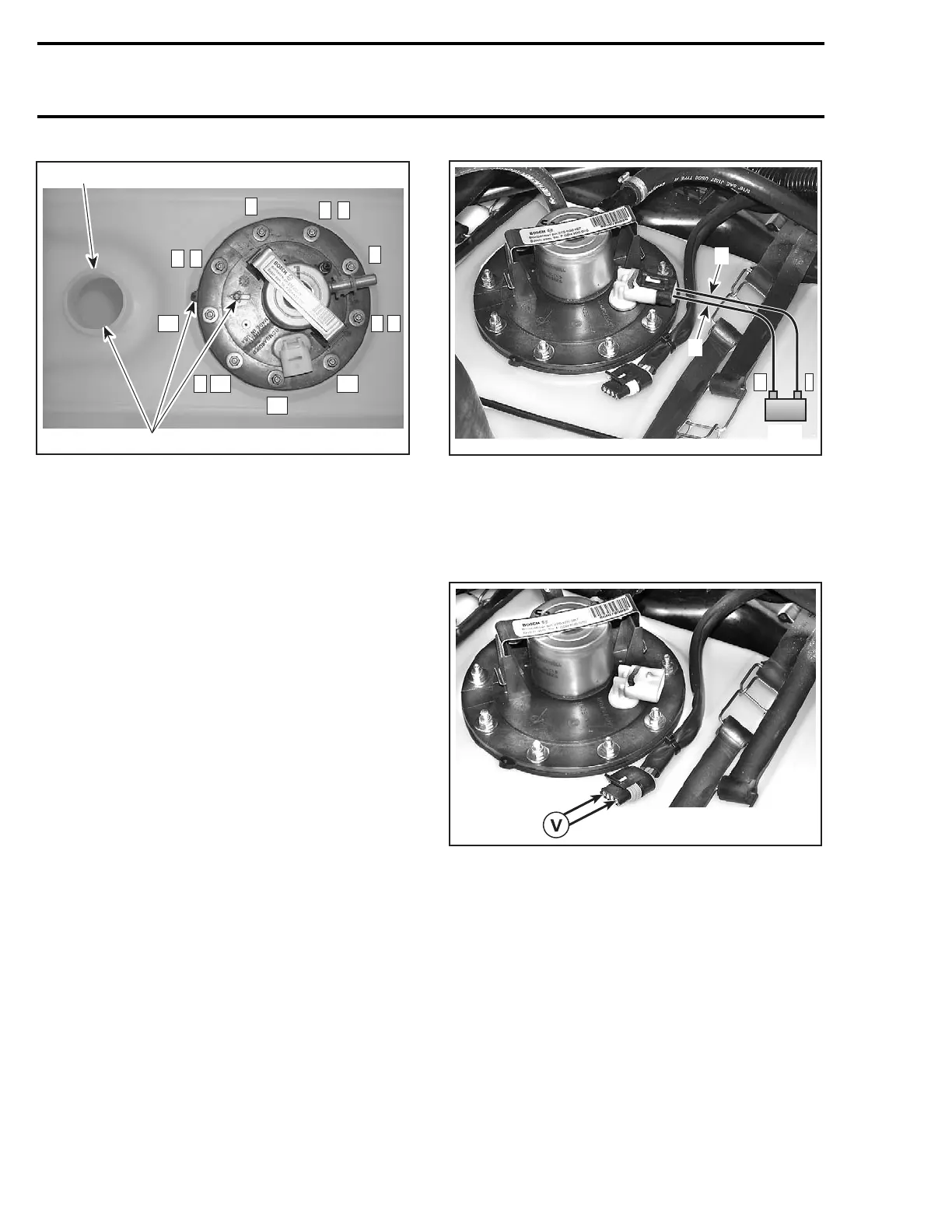

Fuel Pump

When connecting the safety lanyard to the DESS

post, the fuel pump should run for 2 seconds to

build up the pressure in the system.

If the pump does not work, disconnect the con-

nector from the fuel pump.

Install a temporary connector on the fuel pump

with wires long enough to make the connection

outside the bilge.

+ -

F18F0TA

D

A

BAT

CAUTION: Running pump a few minutes with

reverse polarity can damage the pump.

If pump does not run, replace the fuel pump mod-

ule.

Otherwise, probe terminals as shown.

F18F0UA

D

A

When installing safety lanyard, you should read

battery voltage for approximately 2 seconds (then

voltage will drop to approximately 11 V).

If battery voltage is read, the problem can be in

fuel pump or in harness connector. Repair or re-

place appropriate part.

If battery voltage is not read, probe terminals as

shown.

140 smr2005-014

Loading...

Loading...