Section07PROPULSION

Subsection 02 (DRIVE SYSTEM)

F01I0FA

321

TYPICAL

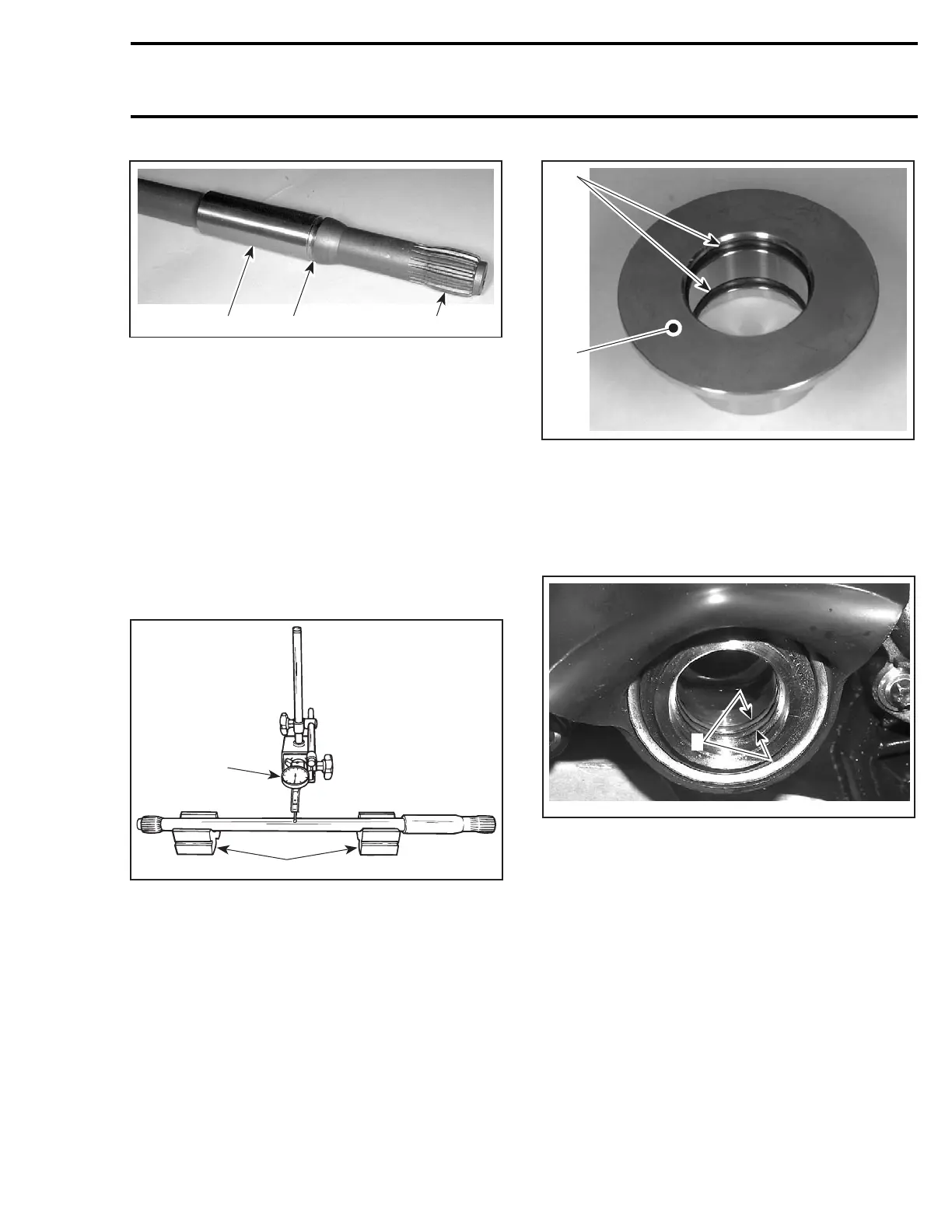

1. Surface condition

2. Groove condition

3. Splines condition

Excessive deflection could cause vibration and

damage to drive shaft splines, impeller, flywheel

or floating ring.

Place drive shaft on V-blocks and set-up a dial

gauge in center of shaft. Slowly rotate shaft; dif-

ference between highest and lowest dial gauge

reading is deflection. Refer to the following illus-

tration.

Maximum permissible deflection is 0.5 mm

(.020 in).

1

2

F01J15A

MEASURING DRIVE SHAFT DEFLECTION

1. Dial gauge

2. V-blocks

Damper

4-TEC Models

Discard damper no. 8 to install a new one.

Floating Ring and O-Ring

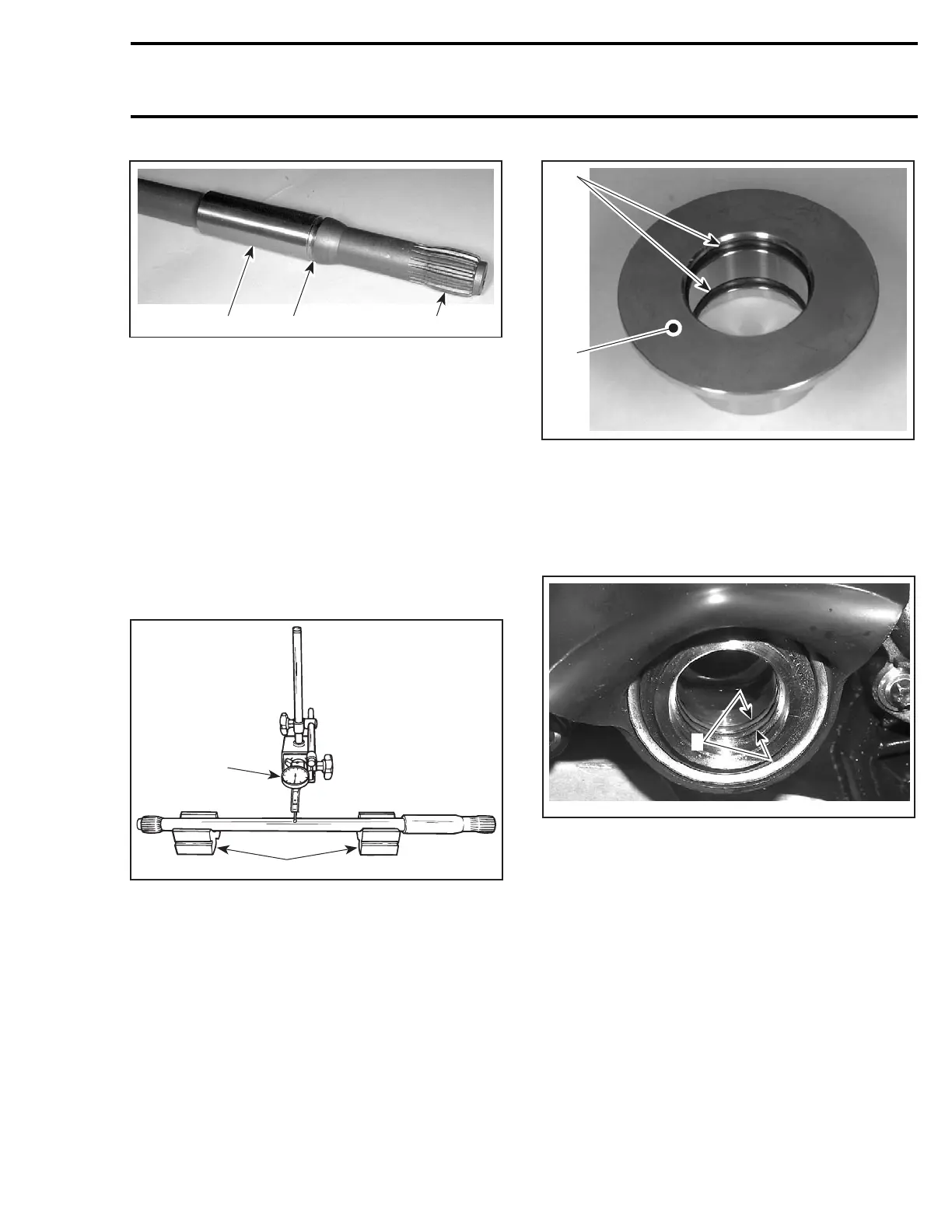

Inspect condition of O-rings no. 9 and floating ring

contact surface.

F01I0GA

1

2

1. O-rings

2. Floating ring contact surface

PTO Seal

Discard both O-rings no. 10 inside PTO seal and

install new ones.

F18C01A

1

1. O-rings

Inspect PTO seal assembly. Refer to PTO

HOUSING/MAGNETO section.

Boot

Inspect the condition of boot. If there is any dam-

age or evidence of wear, replace it.

INSTALLATION

Installation is essentially the reverse of removal

procedure. However, pay particular attention to

the following.

smr2005-020 209

Loading...

Loading...