Section 07 PROPULSION

Subsection 02 (DRIVE SYSTEM)

Drive Shaft

NOTE: Ensure to install floating ring no. 1 before

inserting the drive shaft no. 3 in PTO seal assem-

bly.

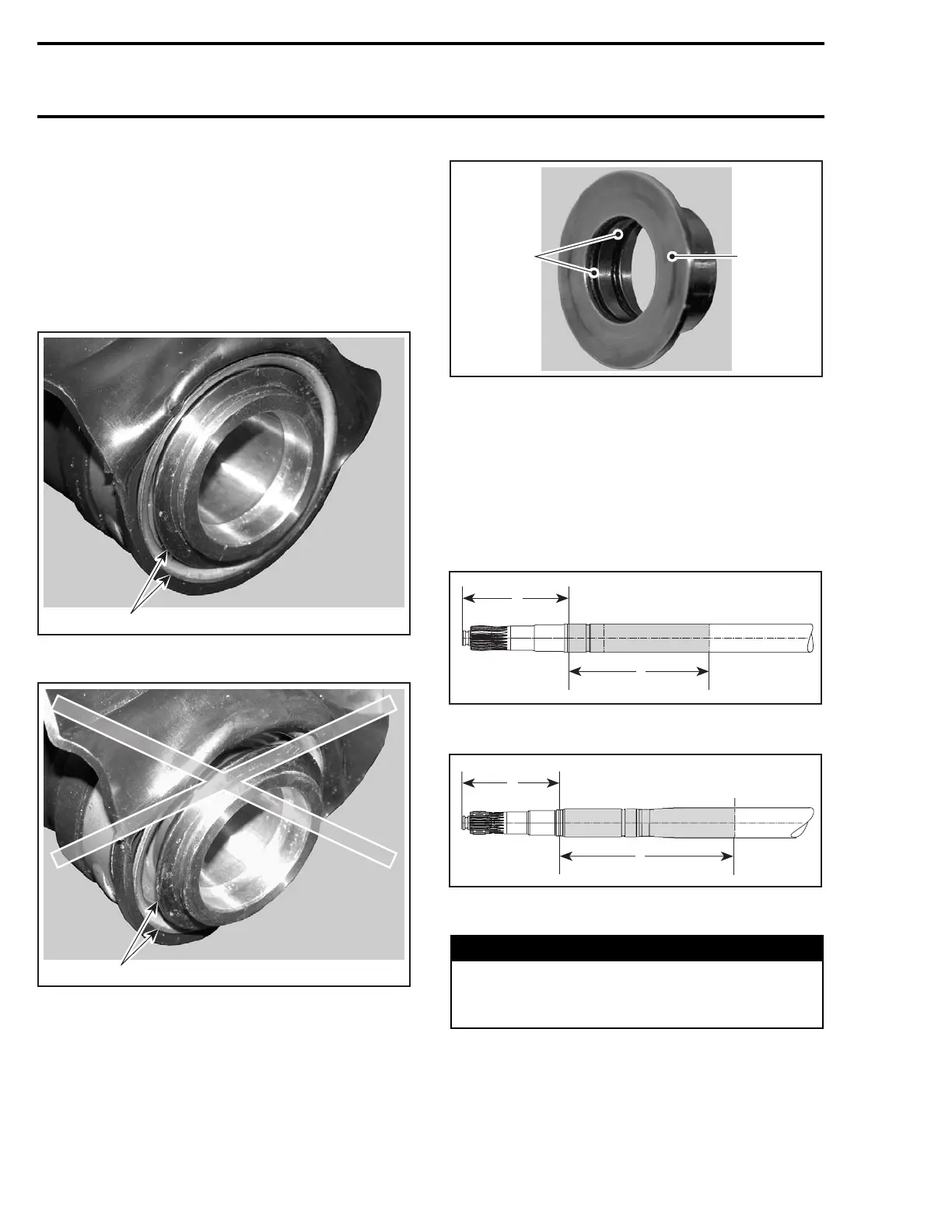

Before installing drive shaft, inspect PTO seal as-

sembly. The inner sleeve must be flush with outer

circumference of the assembly. Otherwise, gen-

tly push or tap on inner sleeve until flush.

F18I0EA

1

CORRECT INSTALLATION

1. Inner sleeve flush with outer circumference

F18I0FA

1

WRONG INSTALLATION

1. Inner sleeve not flush with outer circumference

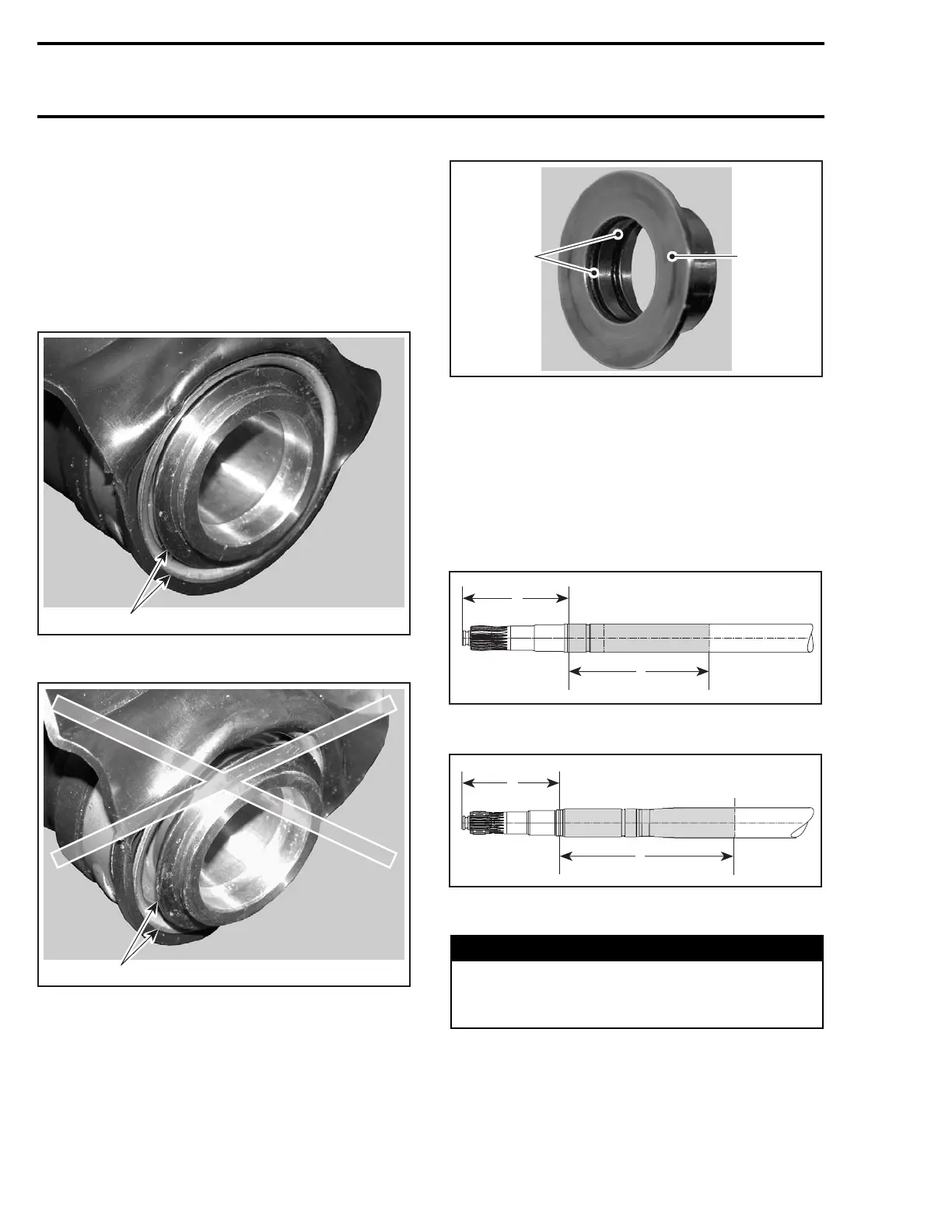

Apply a thin coat of synthetic grease (P/N 293 550

010) on the floating ring O-rings no. 9. Do not get

grease on floating ring sealing surface.

1

F18I0KA

2

1. Synthetic grease

2. No lubrication

To prevent possible drive shaft corrosion, apply

anti-corrosion spray (P/N 219 700 304) on drive

shaft where shown.

NOTE: Drive shaft should be dry and clean prior

to applying the corrosion protectant. If the drive

shaft is corroded, a rotating wire brush may be

used.

A

F18J25A

B

A. 89 mm (3.3 in)

B. 131 mm (5.2 in) — zone to apply primer

F19J0BA

A

B

A. 101mm(4in)

B. 180 mm (7.1 in) — zone to apply primer

WARNING

Always work in a well ventilated area. Care-

fully read application instructions on product

can.

Wait 2 hours prior to using the watercraft to allow

protectant to dry.

210 smr2005-020

Loading...

Loading...