Section 07 PROPULSION

Subsection 04 (VARIABLE TRIM SYSTEM)

INSPECTION

Rubber Boot

Make sure rubber boot no. 3 is in good condition.

If it is cracked or torn, replace boot.

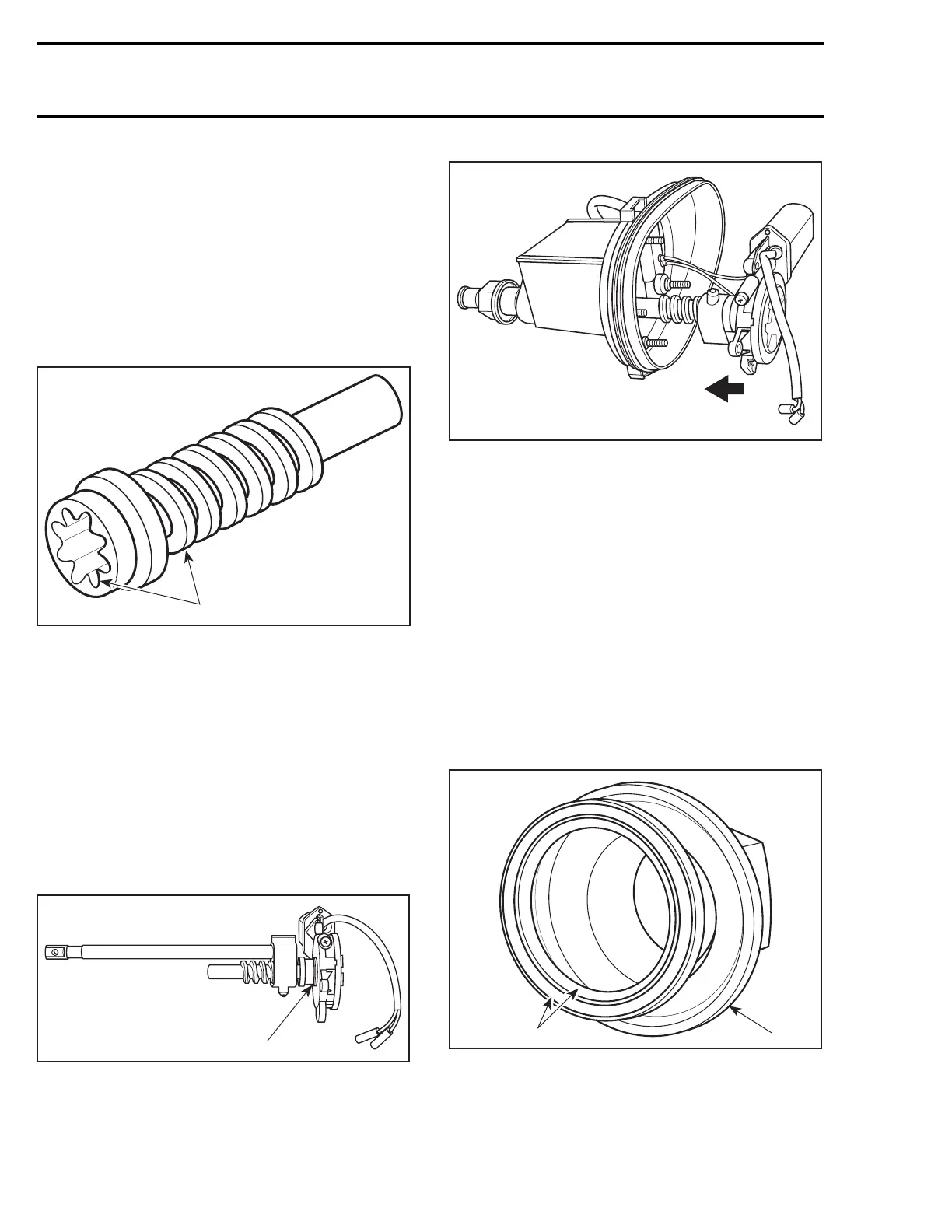

Worm

Inspect threads and splines of worm no. 9 for

wear. If worm replacement is necessary, renew

also sliding shaft.

F01J25A

1

1. Inspect threads and splines

ASSEMBLY

Assembly is essentially the reverse of disassem-

bly procedures. However pay particular attention

to the following.

Motor, Worm and Sliding Shaft

Apply synthetic grease (P/N 293 550 010) to

worm.

Screw worm no. 9 to sliding shaft no. 10.

Mesh worm splines to gear of motor.

F01J2PA

1

1. Mesh worm spline to gear of motor

Install motor no. 8, worm and sliding shaft in VTS

housing.

F01J2GA

Tighten nuts no. 11 to7N•m(62lbf•in).

Connect wires of motor.

CAUTION: Make sure wire color codes match.

Install cover no. 7.

NOTE: Make sure seal no. 12 is in place.

INSTALLATION

Installation is essentially the reverse of removal

procedures. However pay particular attention to

the following.

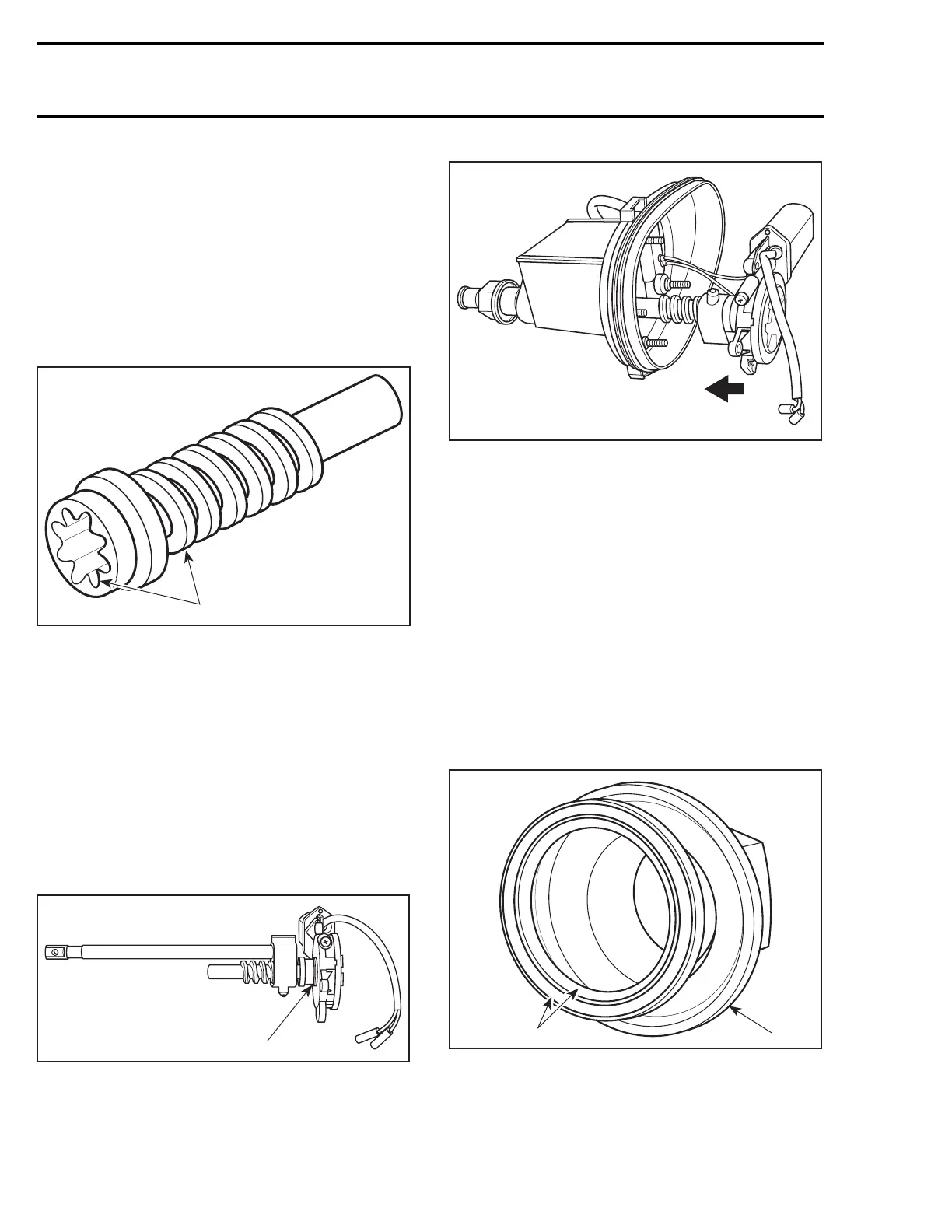

Nut and Sealing Washer

Place sealing washer no. 5 on nut no. 4. Make

sure seal lips are facing toward hull.

F01J2LA

1

2

1. Seal lips facing hull

2. Nut

Apply Loctite Primer N (P/N 293 800 041) to

threads of VTS housing, and to nut no. 4.

224 smr2005-028

Loading...

Loading...