Section 08 STEERING SYSTEM

Subsection 02 (OFF-POWER ASSISTED STEERING SYSTEM (O.P.A.S.))

smr05-039-007

UPPER SPLIT RING

Install removed parts in the cylinder.

Using the O.P.A.S. cylinder nut wrench (P/N 529

035 840) torque the cylinder cap to 7 N•m

(62 lbf•in). After tightening, keep turning the cap

until the locking tab goes over the stopper.

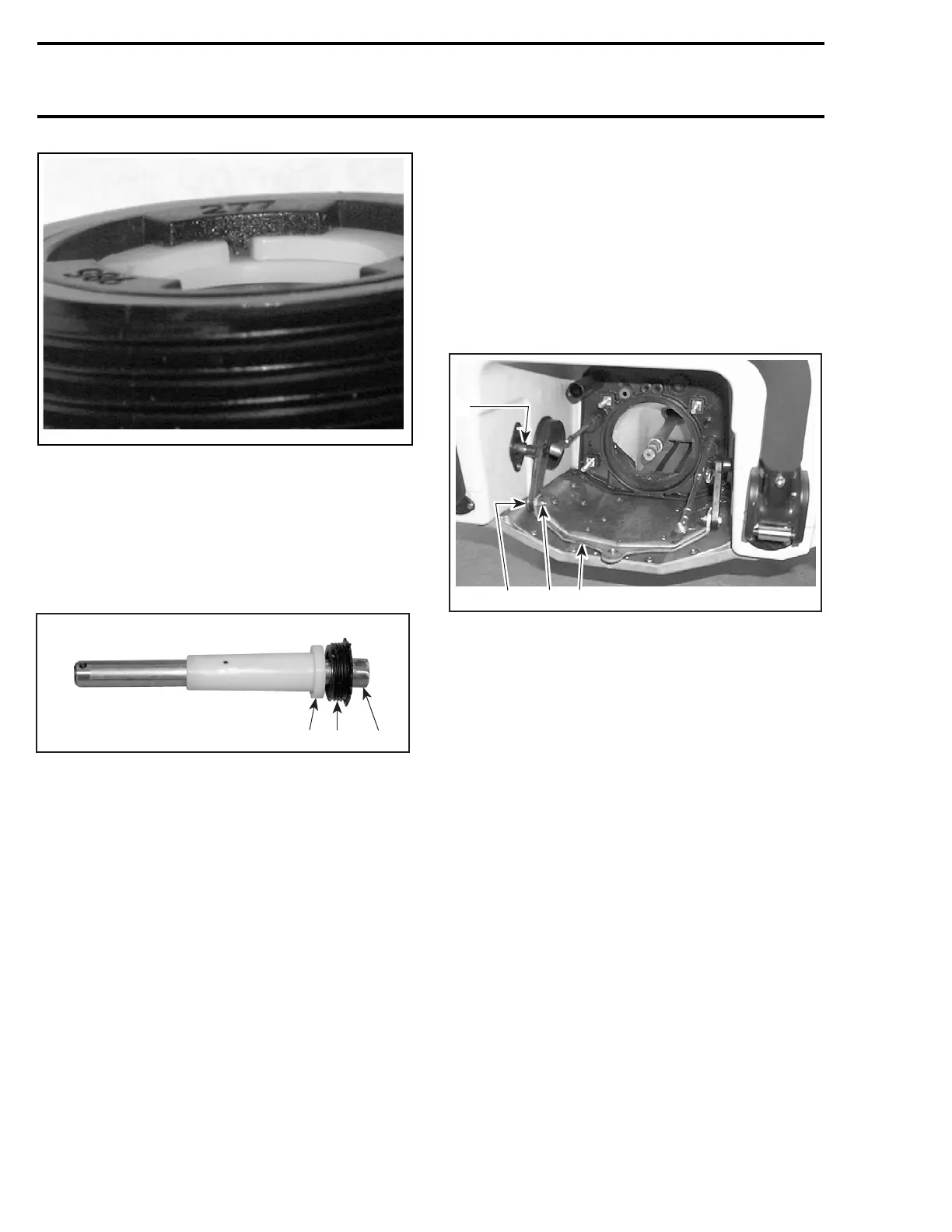

RXT Models

1

F19J0DA

2

3

1. Pivot rod

2. Spacer

3. Cylinder cap assembly

The cylinder disassembly is not necessary for

these models.

Check pivot rod no. 4 for cracks or scratches. Re-

place pivot rod, if necessary.

Installation

The installation is the reverse of the removal pro-

cedure. However, pay attention to the following

detail.

Perform the tie-rod fitting adjustment. See above.

TIE ROD

Removal

Removal procedure for RH and LH tie rod no. 7 is

same.

Remove side vane no. 1 and cylinder support no. 6

as mentioned above.

Remove O.P.A.S. “U” lever screw no. 17,flat

washer no. 18, bushing no. 19 and venturi bush-

ing no. 20 from nozzle.

Removejetpump(refertoJETPUMP).

Remove screw no. 21 and washers no. 22 to re-

move “U” lever no. 23 from tie rod connecting

levers no. 24.

2

F18K0RA

13

4

TYPICAL

1. “U” lever screw

2. Screw

3. Tie rod connecting lever

4. Tie rod

Pull tie rod out from jet pump side with the sealed

tube no. 25.

Unscrew lever from the tie rod.

Installation

Installation is the reverse process of removal.

Torque screw no. 21 to 7 N•m(62lbf•in).

Torque O.P.A.S. “U” lever screw no. 17 to 20 N•m

(15 lbf•ft).

SEALED TUBE

Removal

Removal procedure for RH and LH sealed tube

no. 25 is same.

Remove side van no. 1, cylinder housing no. 6 and

O.P.A.S. “U” lever no. 23 as mentioned above.

Removejetpump(refertoJETPUMP).

Remove Phillips screws no. 26 and remove rod

grommet no. 27.

246 smr2005-039

Loading...

Loading...