Section06ELECTRICALSYSTEM

Subsection 03 (STARTING SYSTEM)

WARNING

Always wear safety glasses when using com-

pressed air.

Remove dirt, oil or grease from commutator using

a clean cloth soaked in suitable solvent. Dry well

using a clean, dry cloth.

Clean engine ring gear teeth and drive unit (clutch).

NOTE: Bushings or bearings must not be cleaned

with grease dissolving agents.

Immerse all metal components in cleaning solu-

tion. Dry using a clean, dry cloth.

STARTER INSPECTION

Armature

NOTE: An ohmmeter may be used for the follow-

ing testing procedures, except for the one con-

cerning shorted windings in armature.

Check commutator for roughness, burnt or scored

surface. If necessary, turn commutator on a lathe,

enough to resurface only.

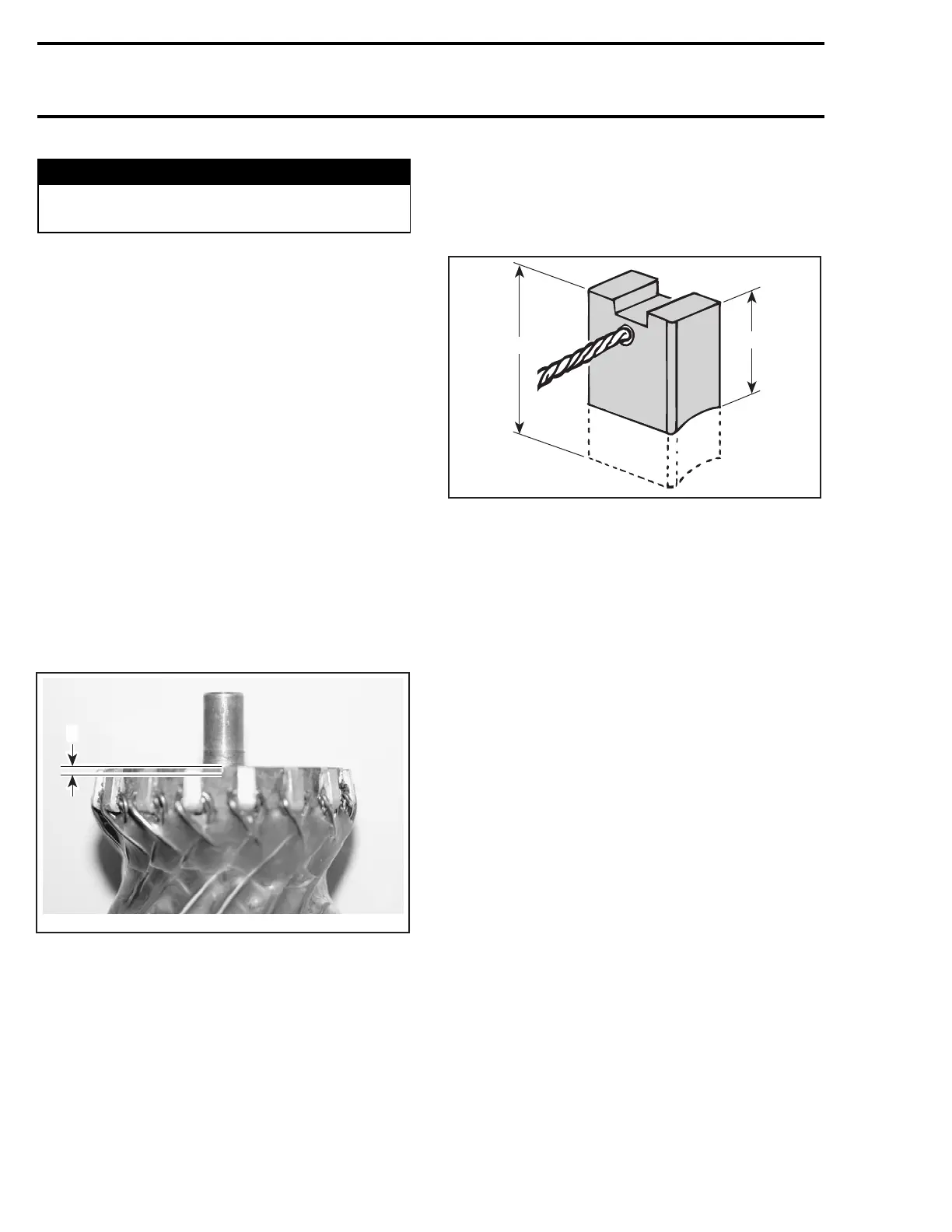

Check commutator condition with an indicator. If

out of specification, replace the starter.

1

F18H0RA

1. Commutator undercut 0.20 mm (.008 in)

Brush Holder

Check brush holder for insulation using an ohm-

meter. Place one test probe on insulated brush

holder and the other test probe on brush holder

plate. If continuity is found, brush holder has to

be repaired or replaced.

Brush

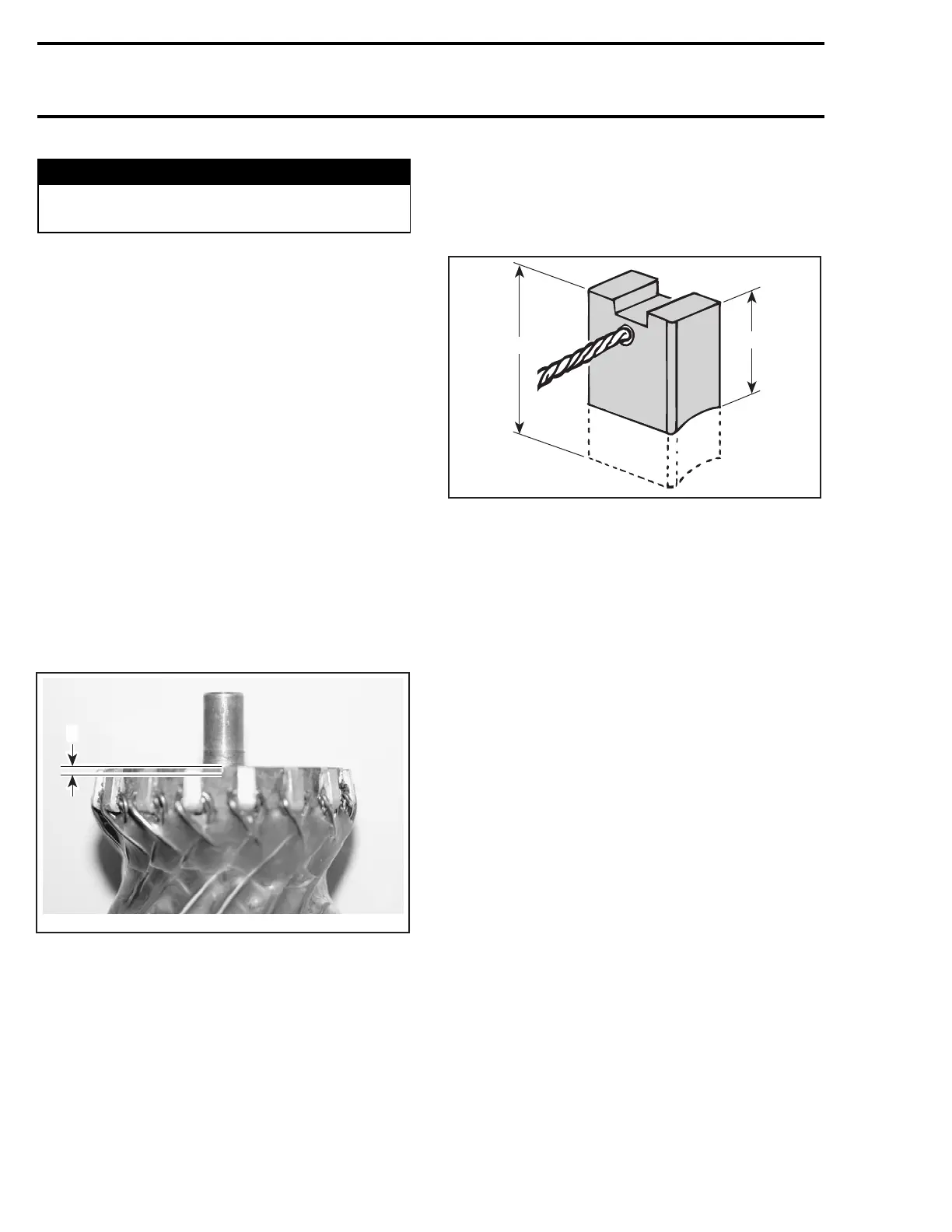

Measure brush length. If less than 8.5 mm

(.335 in), replace them.

NOTE: New brush length is 12 mm (.472 in).

A03E05A

1

2

1. New

2. Wear limit, 8.5 mm (.335 in)

STARTER ASSEMBLY

Reverse the order of disassembly to reassemble

starter.

STARTER INSTALLATION

Installation is essentially the reverse of removal

procedure. However, pay particular attention to

the following.

Make sure that starter and engine mating surfaces

are free of debris. Serious trouble may arise if

starter is not properly aligned.

Apply grease Isoflex Topas NB52 (P/N 293 550

021) on O-rings of starter.

Install starter.

NOTE: If starter does not mesh properly, try to pull

it out and slightly rotate the starter gear; then re-

install starter. One could also temporarily remove

both O-rings, properly mesh gears then remove

starter to reinstall O-rings, being careful not to ro-

tate gear to keep its position, to finally reinstall

starter.

Apply Loctite 243 (P/N 290 897 651) on retaining

screws no. 1 andtorqueto10N•m(89lbf•in).

Connect the RED positive cable to the starter and

torque nut to 7 N•m(62lbf•in). Apply dielectric

grease (P/N 293 550 004) on terminal and nut.

170 smr2005-017

Loading...

Loading...