Section07PROPULSION

Subsection 01 (JET PUMP)

Remove large O-ring no. 37 from pump housing.

Wear Ring

Inspectwearringbeforeremovingit. SeePARTS

INSPECTION further.

Remove the screws no. 38 retaining wear ring

no. 4 in the jet pump housing no. 27.

Place jet pump housing in a vise with soft jaws. It

is best to clamp housing using a lower ear.

Cutwearringattwoplaces.

CAUTION: When cutting ring, be careful not to

damage jet pump housing.

NOTE: Wear ring can be cut using a jigsaw, a small

grinder or a low clearance hacksaw such as Snap-

on HS3 or equivalent.

After cutting ring, insert a screwdriver blade be-

tween jet pump housing and ring outside diame-

ter.

Push ring so that it can collapse internally.

Pull ring out.

CLEANING

Properly clean all threads.

Remove all O-rings and clean parts in a solvent.

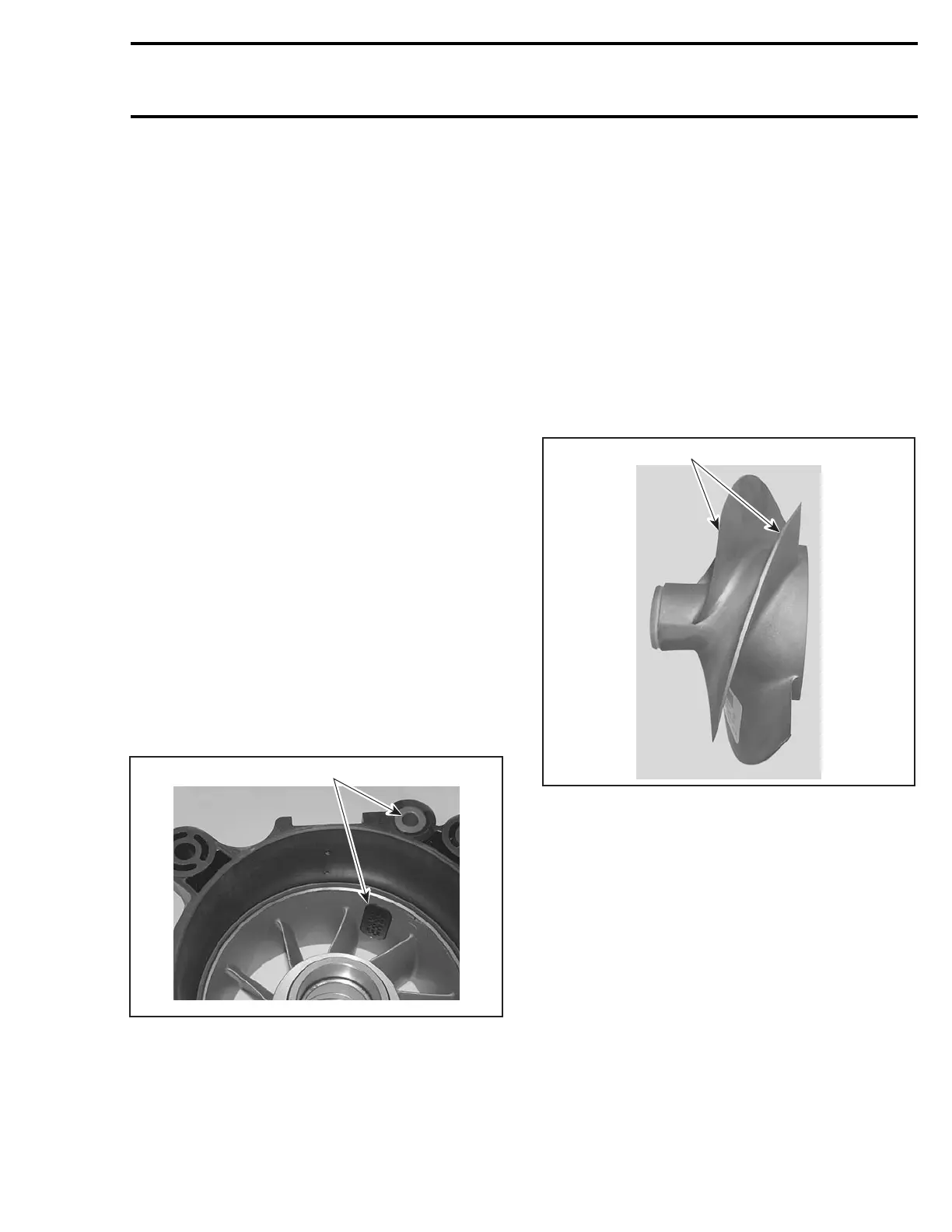

Carefully check water passages. Blow low pres-

sure compressed air through them and make sure

they are clear.

1

F18J0XA

1. Water passages

Brush and clean impeller shaft threads, impeller

and drive shaft splines with pulley flange cleaner

(P/N 413 711 809) or equivalent. Free threads and

splines from any residue.

PARTS INSPECTION

Impeller

Visually inspect impeller splines. Check for wear

or deformation. Renew parts if damaged.

NOTE: Check also PTO flywheel and drive shaft

condition. Refer to DRIVE SYSTEM and 1503 EN-

GINE SHOP MANUAL.

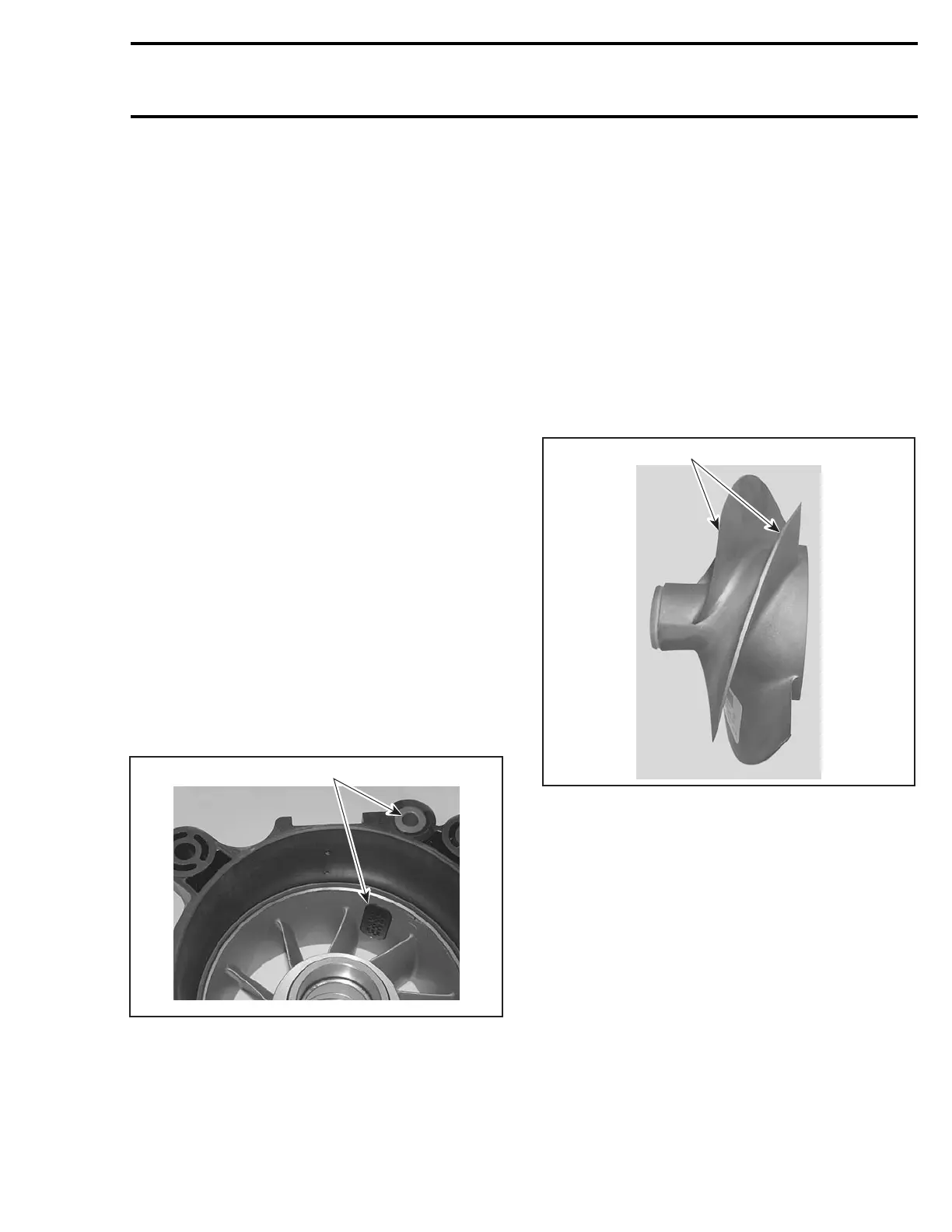

Examine impeller in wear ring for distortion.

Check if blade tips are blunted round, chipped or

broken. Such impeller is unbalanced and will vi-

brate and damage wear ring, impeller shaft, shaft

seal or bearings. Renew if damaged.

1

F18J1BA

1. Replaced if blunted round or damaged

Check impeller for cavitation damage, deep

scratches or any other damage.

smr2005-019 193

Loading...

Loading...