Section07PROPULSION

Subsection 02 (DRIVE SYSTEM)

GENERAL

Jet pump must be removed to replace any com-

ponents of the drive system. Refer to JET PUMP

for removal procedure.

REMOVAL

Drive Shaft

NOTE: When drive shaft will be removed, some

oil will flow out. To prevent it, start engine, run at

4000 RPM for 10 seconds and stop engine at this

RPM. This will move oil out of PTO housing into

oil tank. If engine cannot be started, refer to the

procedure in PTO HOUSING/MAGNETO section

and look for PTO HOUSING REMOVAL.

Remove seat.

RXP Models

Remove engine cover.

All Other Models

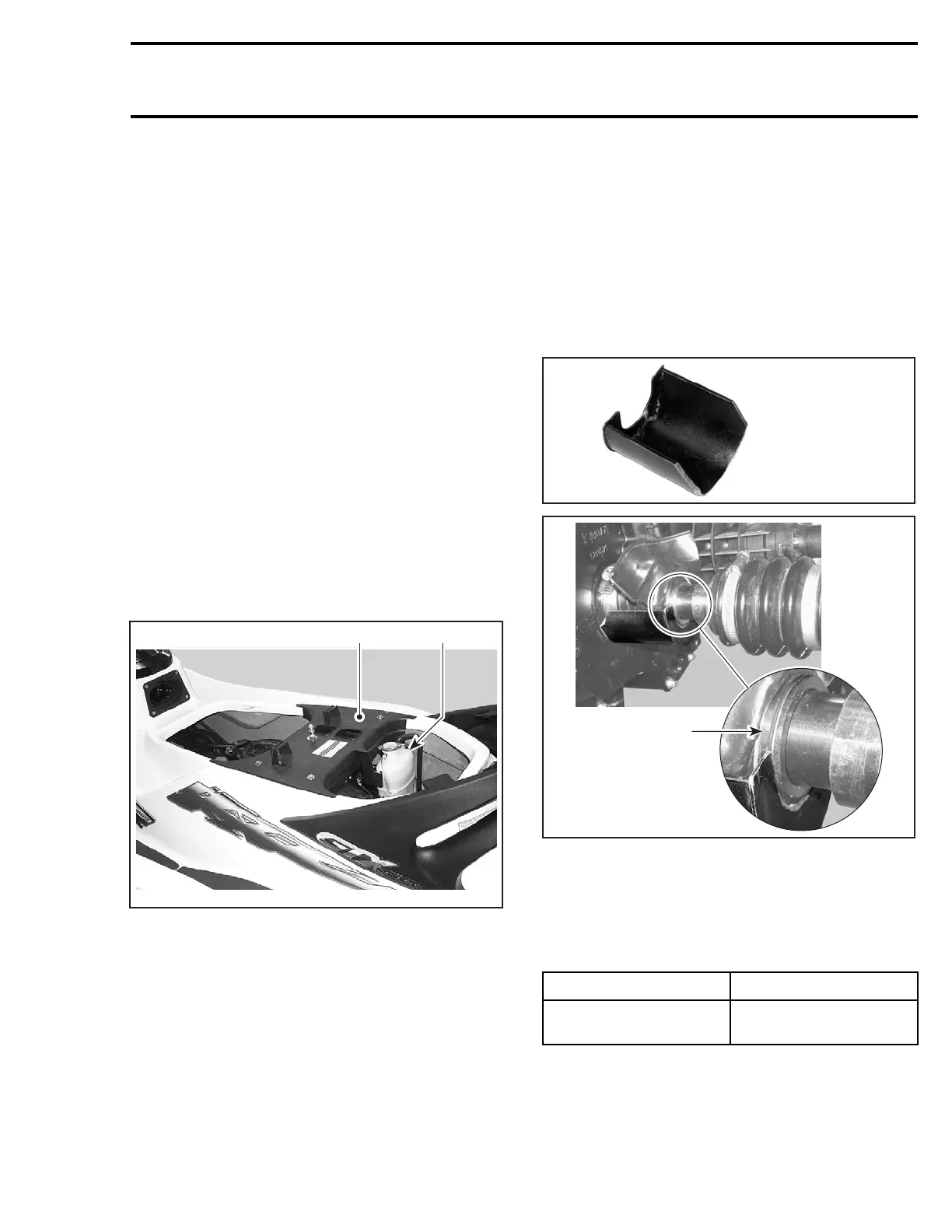

Detach coolant expansion reservoir from vent

tube support then move away.

2

F18L1GB

1

TYPICAL

1. Detach expansion reservoir

2. Remove vent tube support

Detach vent tube.

Remove vent tube support.

All Supercharged Models

Remove supercharger. Refer to AIR INTAKE SYS-

TEM in ENGINE SECTION of this shop manual and

to INTAKE MANIFOLD AND SUPERCHARGER of

the 1503 4-TEC ENGINE SHOP MANUAL.

All Models

NOTE: Use this sequence to minimize the amount

of movement the drive shaft will slide back into

PTO seal assembly.

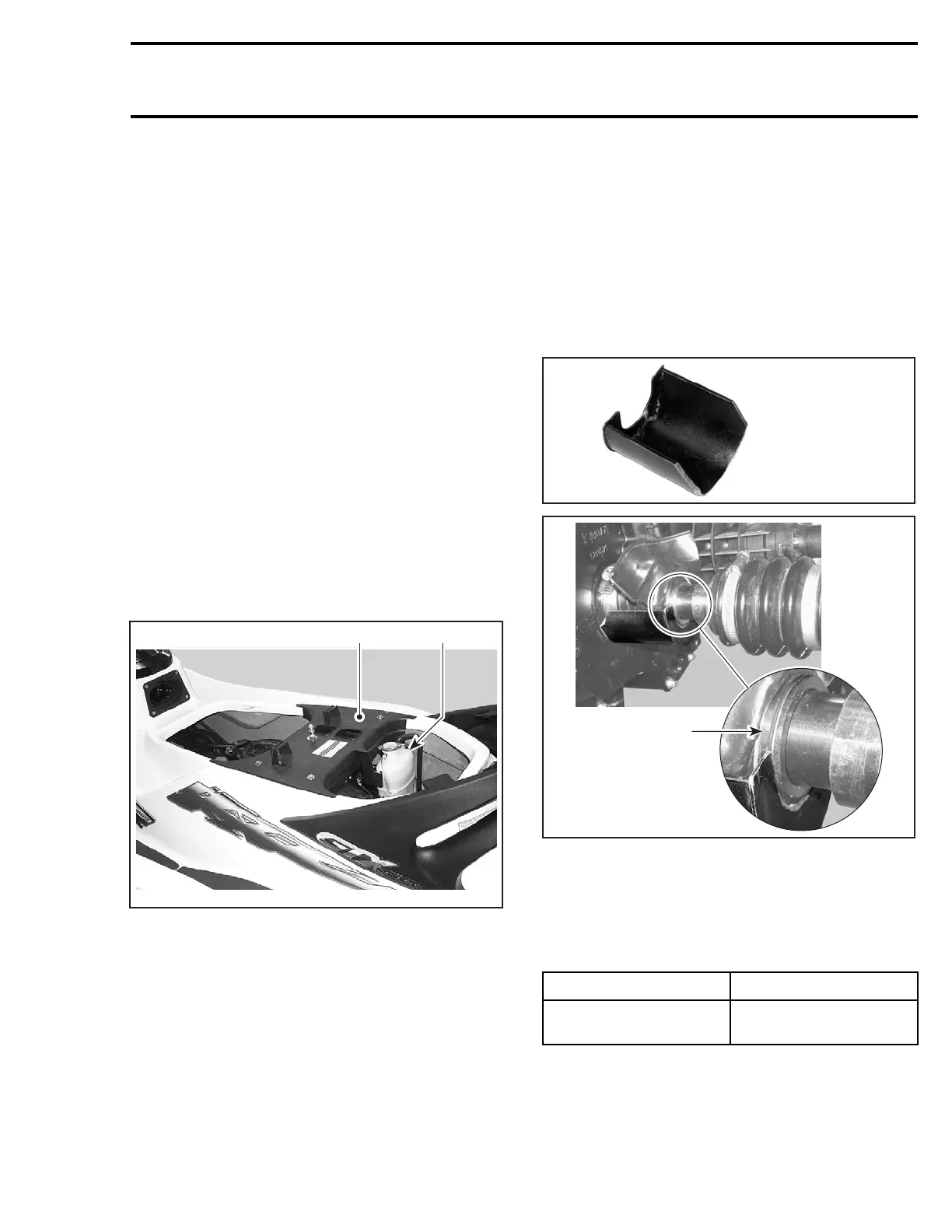

Lift rubber protector to expose PTO seal assem-

bly. Install the PTO seal support tool (P/N 529 035

842) on bottom of PTO seal assembly as shown.

CAUTION: Strictly follow this procedure other-

wise damage to component might occur.

529 035 842

F18I04A

1

1. Insert in groove of PTO seal assembly

Remove jet pump. Refer to JET PUMP section.

Install drive shaft holder on pump support. Refer

to the following table to use the appropriate tool

according to the model.

MODEL TOOL

ALL

Drive shaft holder

(P/N 529 035 986)

NOTE: This is necessary so the drive shaft cannot

move rearwards when using the drive shaft/float-

ing ring tool.

smr2005-020 205

Loading...

Loading...