Section 03 ENGINE SYSTEM

Subsection 04 (EXHAUST SYSTEM)

F18D0LA

TYPICAL

Inspection

Inspect exhaust manifold condition paying atten-

tion for cracks or other damage. Check contact

surfaces and hose. Replace any defective part.

Inspect plane surfaces for warpage. Small defor-

mation can be corrected by grinding surface with

a fine sand paper. Install sand paper on a surface

plate and rub part against oiled sand paper.

Clean all metal components in a solvent.

Installation

Installation is essentially the reverse of removal

procedures. However, pay particular attention to

the following.

NOTE: There is no gasket between cylinder block

and exhaust manifold.

Apply Loctite 518 (P/N 293 800 038) on threads of

screws.

To help holding the manifold while installing

screws, first insert the exhaust manifold into the

exhaust pipe no. 1 then, install the upper front

screw. Continue with the remaining screws.

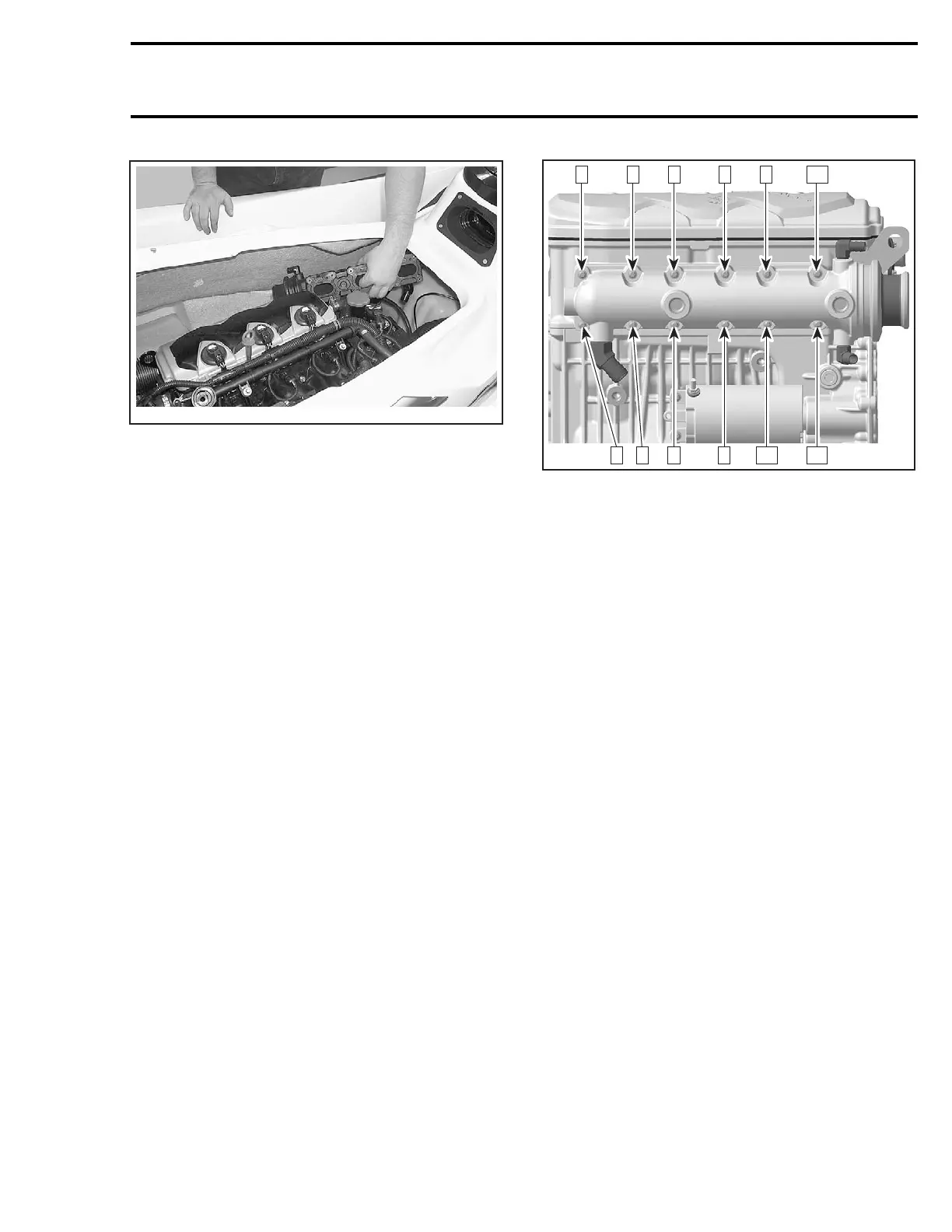

Torquescrewsto10N•m(89lbf•in) as per follow-

ing illustrated sequence. Repeat the procedure,

torquing screws again to 10 N•m(89lbf•in).

R1503motr152A

7 5 1 3 9 11

8 6 4 2 10 12

After installation, ensure there is no coolant or ex-

haust gas leak when the engine is running. Test

run the engine while supplying water to the flush-

ing connector.

CAUTION: Never run engine without supplying

water to the exhaust cooling system when wa-

tercraft is out of water.

MUFFLER

Removal

Remove the exhaust pipe no. 1. See above.

Disconnect the temperature sensor connector.

Disconnect the inlet hose no. 8 then pull muffler

no. 4 outofvehicle.

Inspection

Inspect parts condition paying attention for cracks

or other damage. Check hoses. Replace any de-

fective part.

Installation

Installation is the reverse of the removal proce-

dures.

After installation, ensure there is no coolant or ex-

haust gas leak when the engine is running. Test

run the engine while supplying water to the flush-

ing connector.

CAUTION: Never run engine without supplying

water to the exhaust cooling system when wa-

tercraft is out of water.

smr2005-009 55

Loading...

Loading...