Section 07 BODY AND HULL

Subsection 01 (SUSPENSION (iS))

Reinstall reservoir plug and tighten it to 1 N•m

(9 lbf•in).

Hydraulic Pump Operation Test

Connect a jumper from the positive (30 A fused

jumper) and negative side of the battery to the hy-

draulic pump connector (2-pins connector).

The hydraulic pump should activate and suspen-

sion should go up or down.

Reverse the jumpers and the suspension should

reverse direction.

If the hydraulic pump does not run, check con-

nectors and wires. Replace hydraulic pump as re-

quired.

If hydraulic pump turns, perform the

HYDRAULIC

PUMP CURRENT DRAW

test to confirm pump op-

eration.

Hydraulic Pump Current Draw

If the current draw is to high, the iS module acti-

vates an internal protection.

This operation can be done using B.U.D.S. soft-

ware. Refer to

COMMUNICATION TOOLS AND

B.U.D.S. SOFTWARE

subsection to connect

B.U.D.S.

Activate the suspension by pressing iS up and iS

Down s and check voltage.

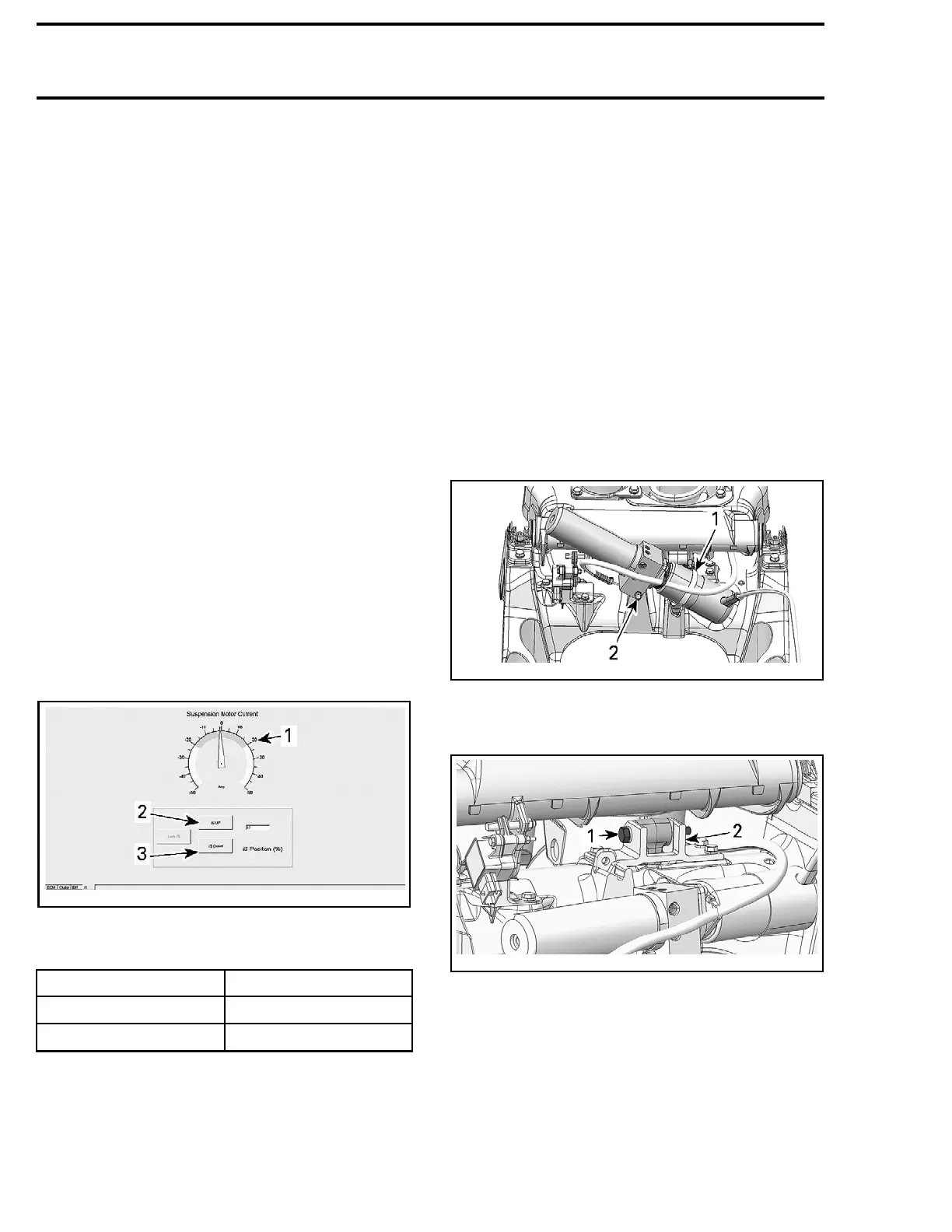

smr2009-041-053_a

ACTIVATI

ON AND IS TABS

1. B.U.D.S. ammeter

2. iS UP

3. iS down

CURRENT

iS UP

16 - 20 A

iS Down

15 - 18 A

If values is near specifications, check connections

and wires.

If wires and connectors are good, perform the iS

module output voltage test. Refer to

IS MODULE

in this subsection.

If the current draw is excessive, replace the hy-

draulic pump.

Hydraulic Pump Removal

(as a Unit with Actuator)

To work on many parts of suspension system, the

removal of the hydraulic pump and actuator as an

unit is necessary.

1. Remove

SHOCK ABSORBER

and

SPRINGS

.

See procedures in this subsection.

2. Unplug the hydraulic pump connector from the

iS module.

3. Cut any locking ties securing the pump harness

to vehicle harness.

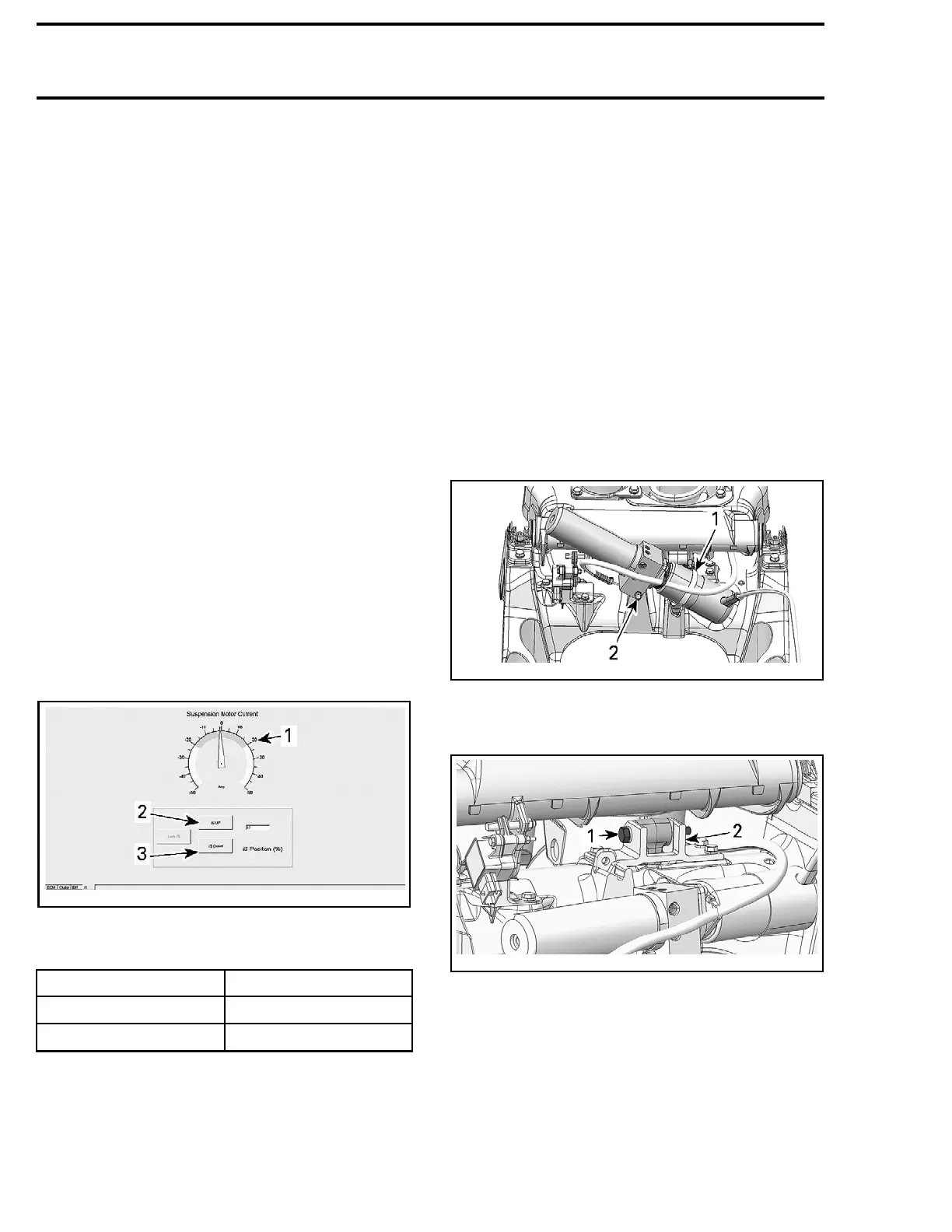

4. Remove clamp and bolt securing the hydraulic

pump from suspension base.

smr2009-041-016_b

1. Hydraulic pump clamp

2. Retaini

ng bolt

5. Remove actuator link bolt.

smr2009-041-029_a

1. Actuator link bolt

2. Link support on the top of suspension base

6. Remove screws retaining the actuator holder.

454 smr2009-041

Loading...

Loading...