Drive Setup CDHD

72 User Manual

5 .3 EM I Suppression

5 .3 .1 CE Filterin g Te ch niqu es

The CDHD drive complies with the CE standards specified in the section

St andards Com pliance. Proper bonding, grounding and filtering techniques must

be applied in order t o m eet this standard.

Noise currents often occur in two types. The first is conducted emissions that are

passed through ground loops. The quality of the system grounding schem e

inversely determines the noise amplitudes in the lines. These conducted

em issions are of a comm on-m ode nature from line to neutral (or ground). The

second is radiat ed high-frequency emissions usually capacitively coupled from

line-to-line and are differential in nature.

To properly m ount the EMI filters, the enclosure should have an unpainted

m et allic surface. This allows for m ore surface area to be in contact wit h the filt er

housing and provides a lower impedance path between this housing and the back

plane. The back panel, in turn, has a high frequency ground strap connection to

the enclosure fram e or earth ground.

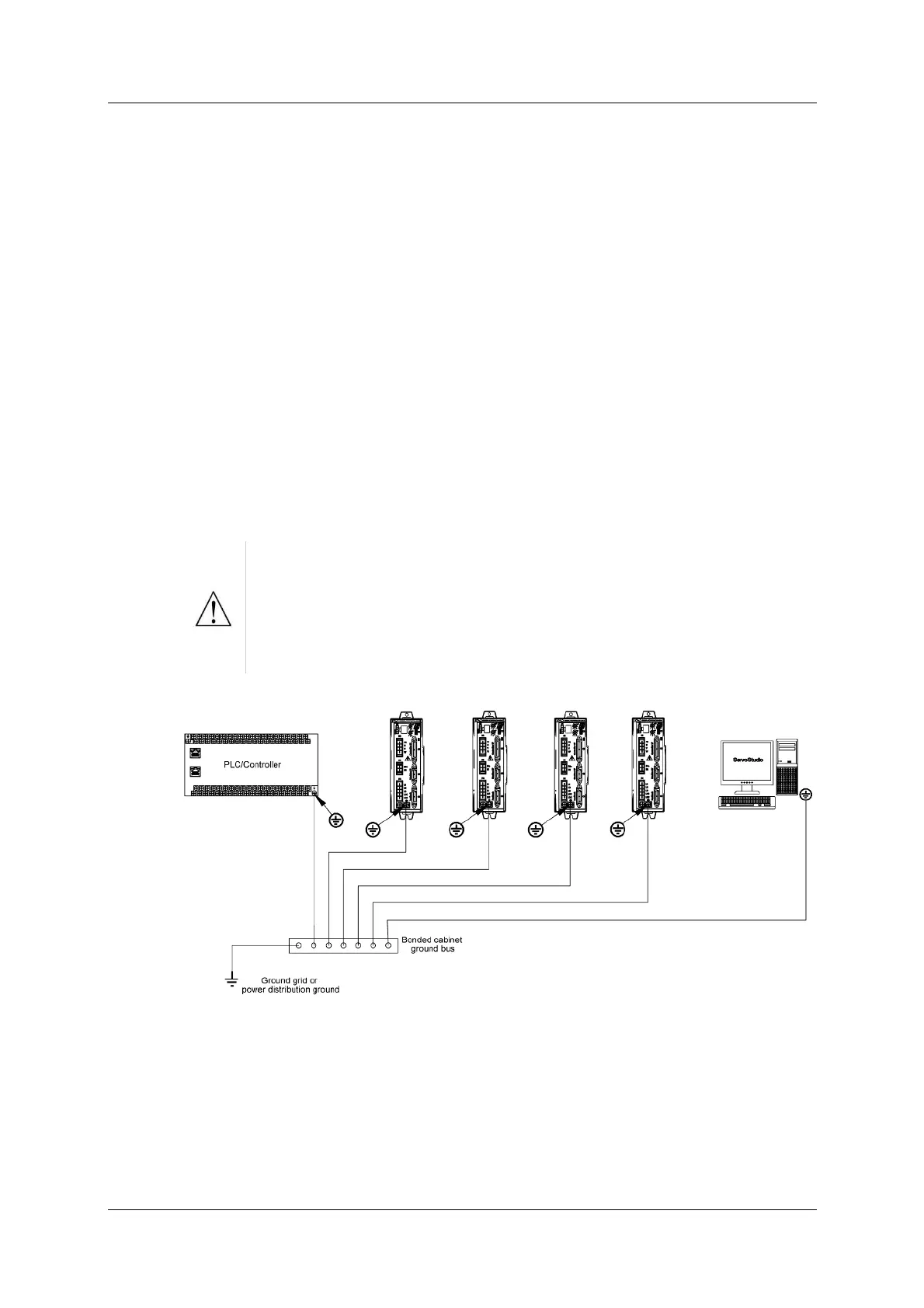

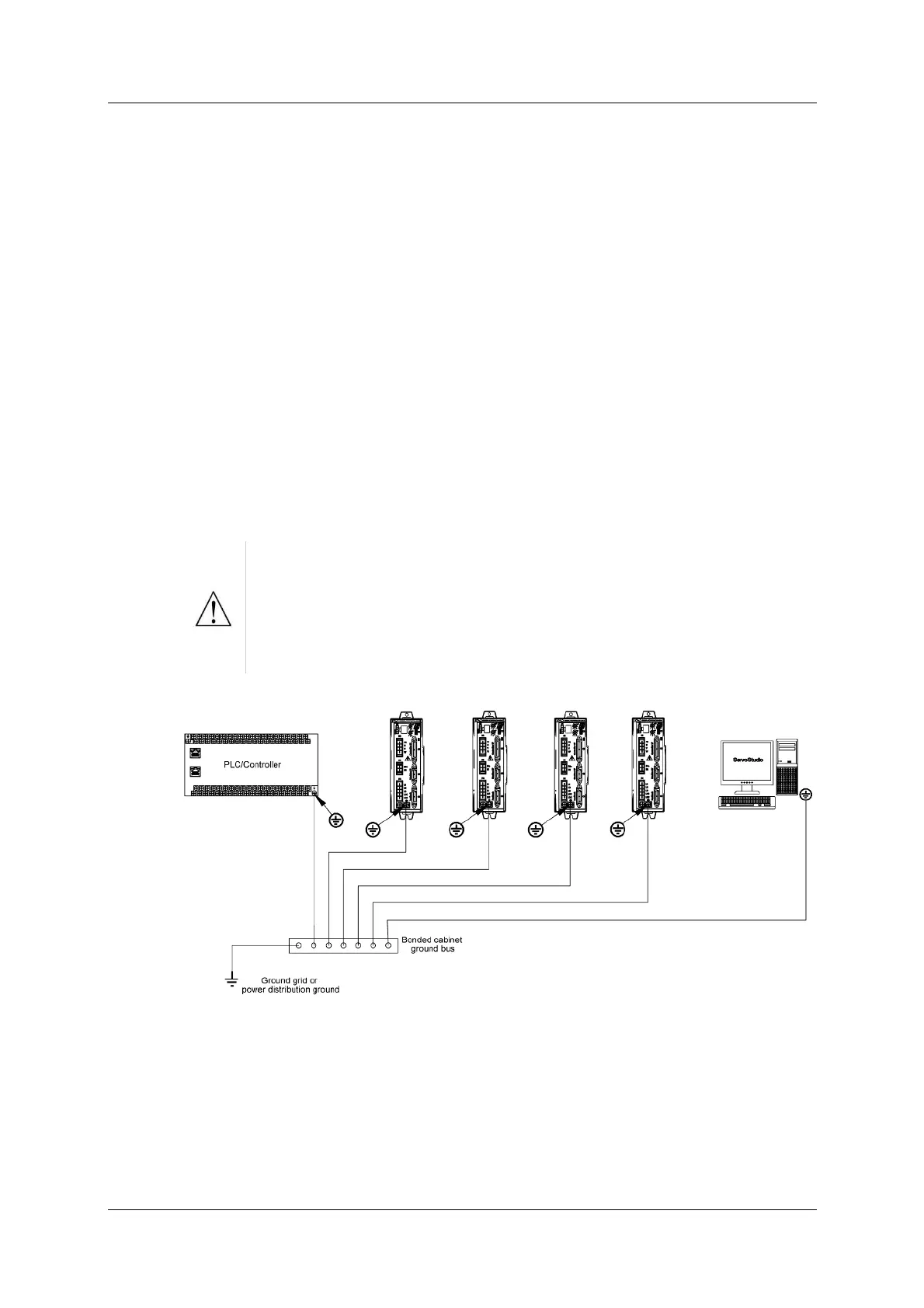

5 .3 .2 Grounding

When connecting the CDHD to other control equipm ent , be sure to

follow two basic guidelines to prevent dam age to t he driv e:

The CDHD m ust be grounded via the earth ground of the main AC

volt age supply.

Any motion controller, PLC or PC that is connected to the CDHD

m ust be grounded to the same earth ground as the CDHD.

Figur e 5 - 2 . CD H D System Grounding

Syst em grounding is essential for proper perform ance of the drive system .

The AC input voltage ground wire must be connected to the PE terminal, located

on the CDHD front panel. This is necessary for bot h safet y and EMI reduction.

Use a single point ground for the system (start wiring) to avoid ground loops.

It is strongly recommended that the CDHD be mounted to a metallic back panel,

and that a high frequency ground be provided t o connect the back panel t o earth

Loading...

Loading...