Operat ion CDHD

190 User Manual

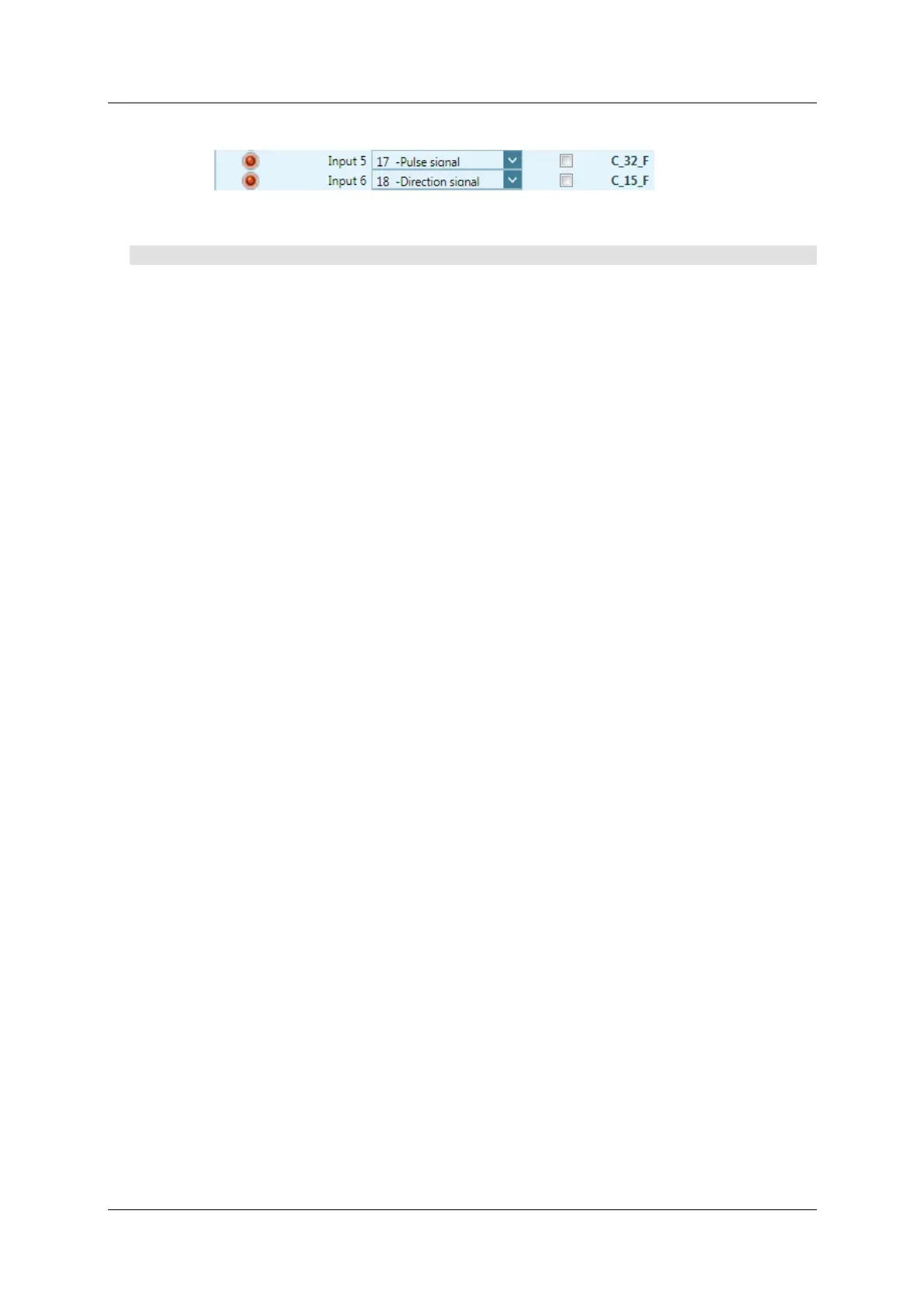

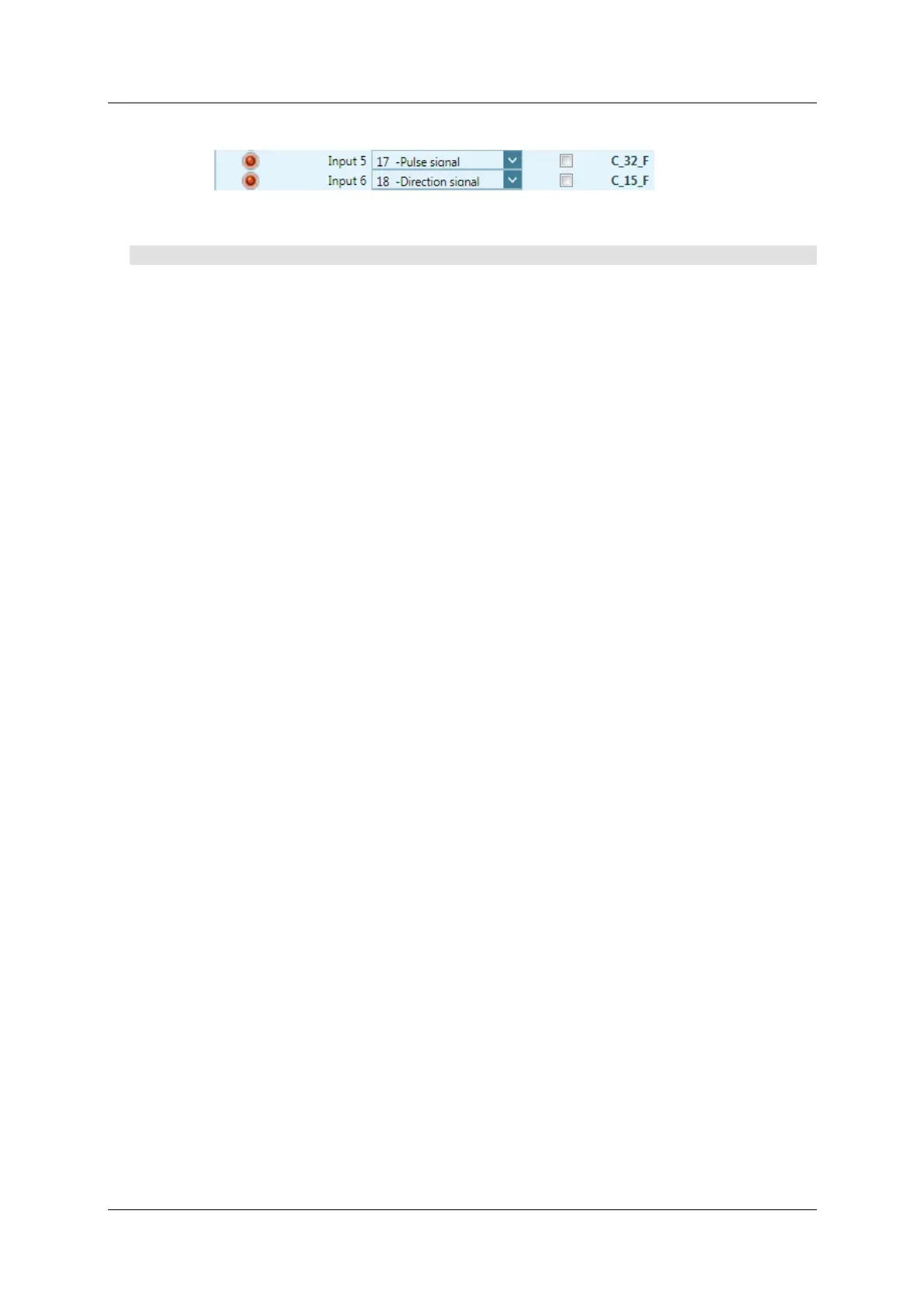

3 . Make sure digital input 6 is set to 1 8 - D ire ction signal.

Figure 8 - 8 . D igit al I nput s for Pulse and Dir ection Sign als

St e p 4 – Se t Pulse and Dir ect ion Param e ters

1 . I n the M ot ion screen, select M u lt iplier .

It is strongly recommended that you enable M ultiplier . This internal CDHD

feature is functional in pulse and direction operation, and improves t he Pulse

and Direction reading.

2 . Make sure the Gear m ode is Enga ge d.

3 . I n the Ratio pane, set the Exte r nal En code r Re solut ion and Rat ios.

The relationship between the number of incoming pulses and the motor

shaft m ovement is determined by the External Encoder Resolution, and the

Gear Ratio Multiplier and Divider (GEARI / GEARO).

For exam ple : A PLC controller is program m ed to provide 1024 line pulses

as an input com m and t o a CDHD syst em in order to m ake the m otor rotate

two revolutions. The settings are therefore:

External Encoder Resolution = 1024

Gear Ratio Multiplier = 2

Gear Ratio Divider = 1

8 .6 .2 M ast e r/ Sla ve – En code r Follow er

In Master/ Slave m ode, the drive follows a quadrature encoder signal generated

by a master device. The direction of m otion is governed by the phase of t he

quadrature signals (A-lead-B or B-lead-A).

The mast er device can be, for exam ple, a handwheel, a m achine master encoder

that is connected to the main camshaft, or the equivalent encoder output of

another servo drive.

I f the m ast er device is a handwheel or a m ast er encoder, then setting XENCRES

equal to the resolution of t he encoder (before quadrature) and setting t he gear

rat io to 1 will result in the m ot or m aking one revolut ion for each revolution on

the input.

As an example, assume the handwheel resolution is 120 lines per revolution

(that is, 480 counts after quadrature). Setting GEARI N= 1, GEAROUT= 1 and

XENCRES= 120 will result in one m ot or revolution for each turn of t he

handwheel.

The quadrature signals can be connected t o either the Controller I / F connect or or

to the Machine I/ F connector. The GEARMODE variable indicates to the drive

where the signals are connected t o.

N ote: The Controller I/ F connector cannot supply voltage to the handwheel or

the m achine m ast er encoder. Only the Machine I / F connector can supply this

volt age (pins 4 and 14 on connect or C3).

Set GEARMODE t o 0 to indicate to the drive t hat the signals are received on

the Pulse and Direction inputs on the Controller I/ F connector (C2) at pins

28 and 11 (Quadrature A), and pins 9 and 27 (Quadrature B).

Loading...

Loading...