Product Description

FLOWSIC100 · Operating Instructions · 8012513/YSA5/V2-1/2016-07 · © SICK Engineering GmbH 35

Subject to change without notice

Control buttons

The following functions are additionally available in the display module:

–Entering parameters for start-up

– Initiating a check cycle

– Switching to Maintenance mode.

2 I/O module

For installation on module carriers, communication via I²C bus, or in rack (MCU in 19”

enclosure), selectable as:

– 2x analog output 0/4 ... 22 mA to output further measured variables (load 500

)

– 2x analog input 0/4 ... 22 mA to read in values from external sensors

3 Interface module

Modules to pass measured values, system status and service information to higher

level control systems, optional for Profibus DP, Ethernet and Modbus, for insertion in

slot (

p. 36, Fig. 21).

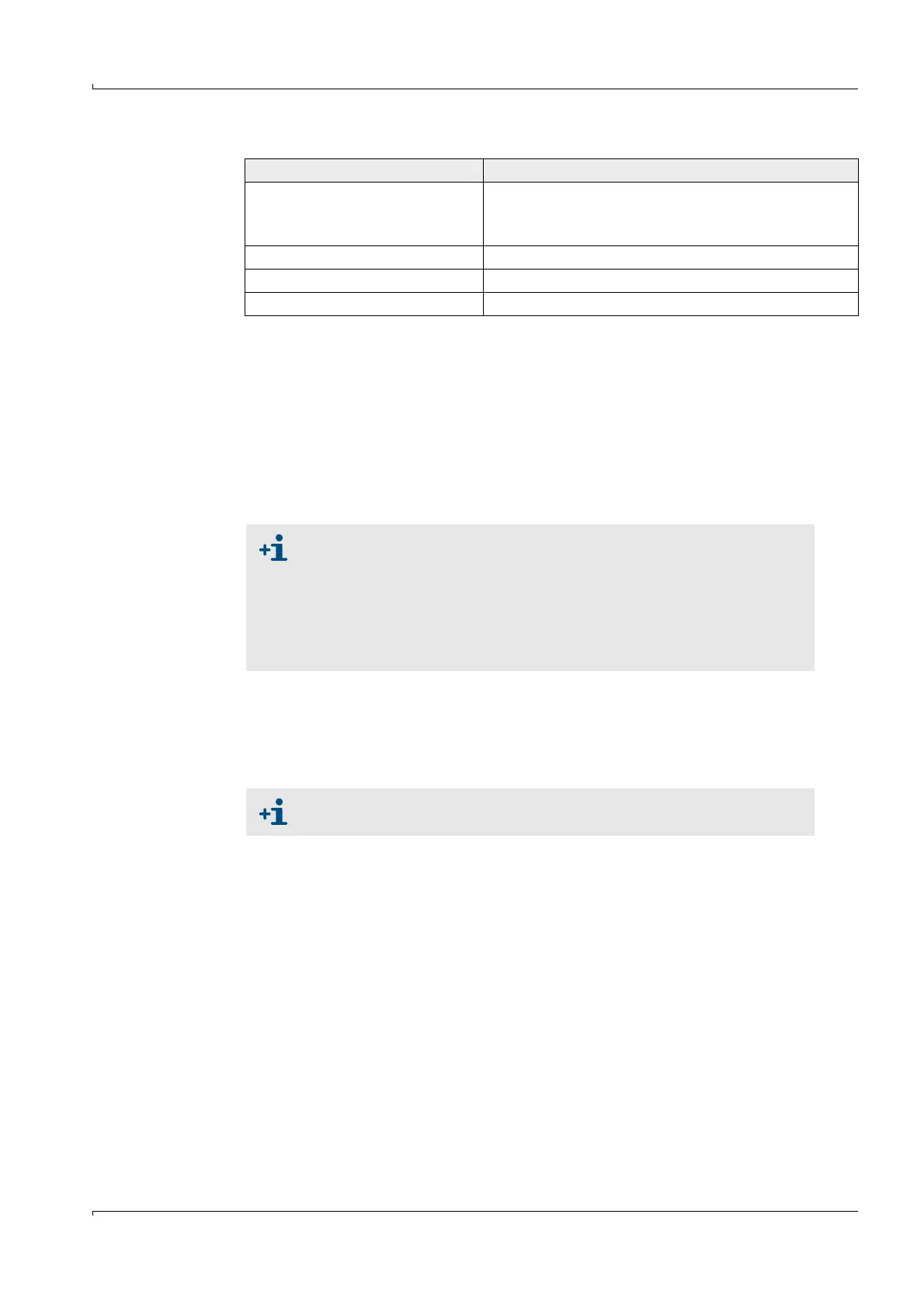

Button Function

Meas

● Selects the single measured value to be displayed

● Toggles between text display and graphical display

● Displays the contrast settings (after 2.5 s)

Arrows ● Selects next/previous measured value screen

Status ● Displays alarm or error messages

Menu ● Display of main menu

● One module carrier is necessary for each module (to insert on top

hat rail). One module carrier has to be connected to the processor

board with a special cable, other module carriers can be docked to

it.

● Maximum for installation and use:

–2 optional AO modules

–1 optional AI module

Profibus DP-V0 for transfers via RS485 according to DIN 19245 Part 3 as

well as IEC 6115

Loading...

Loading...