Line Modules Booksize

3.4 Basic Line Modules with internal air cooling

Booksize power units

238 Manual, (GH2), 06/2008, 6SL3097-2AC00-0BP6

DC link connection and braking resistor connection

100 – 200 kW braking module

Note

After the the DC link voltage has been applied, fault output -X38/5 is "low" for approx.

2 seconds (self test), i.e. in the fault state.

The control unit must suppress this state when switching on the system.

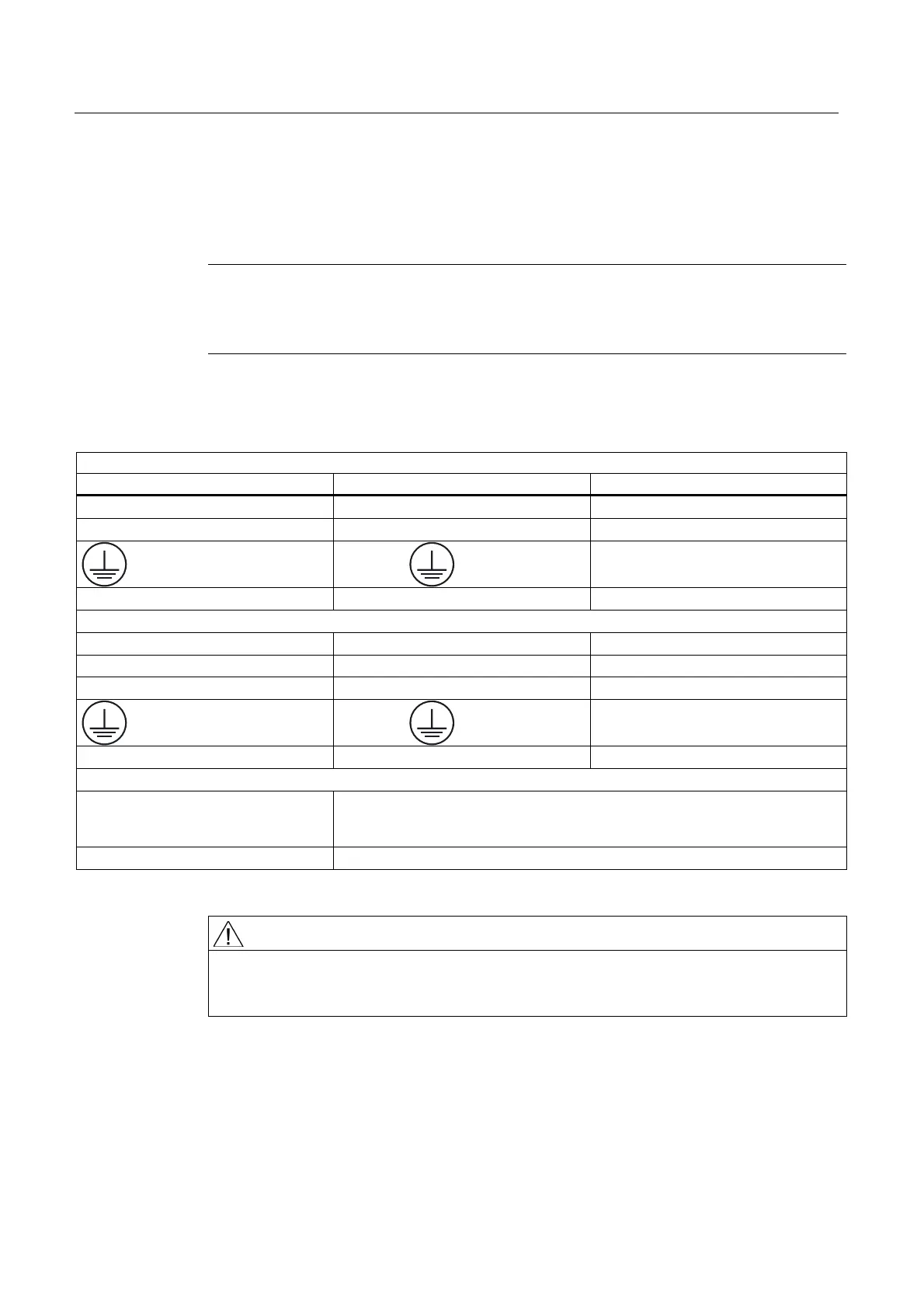

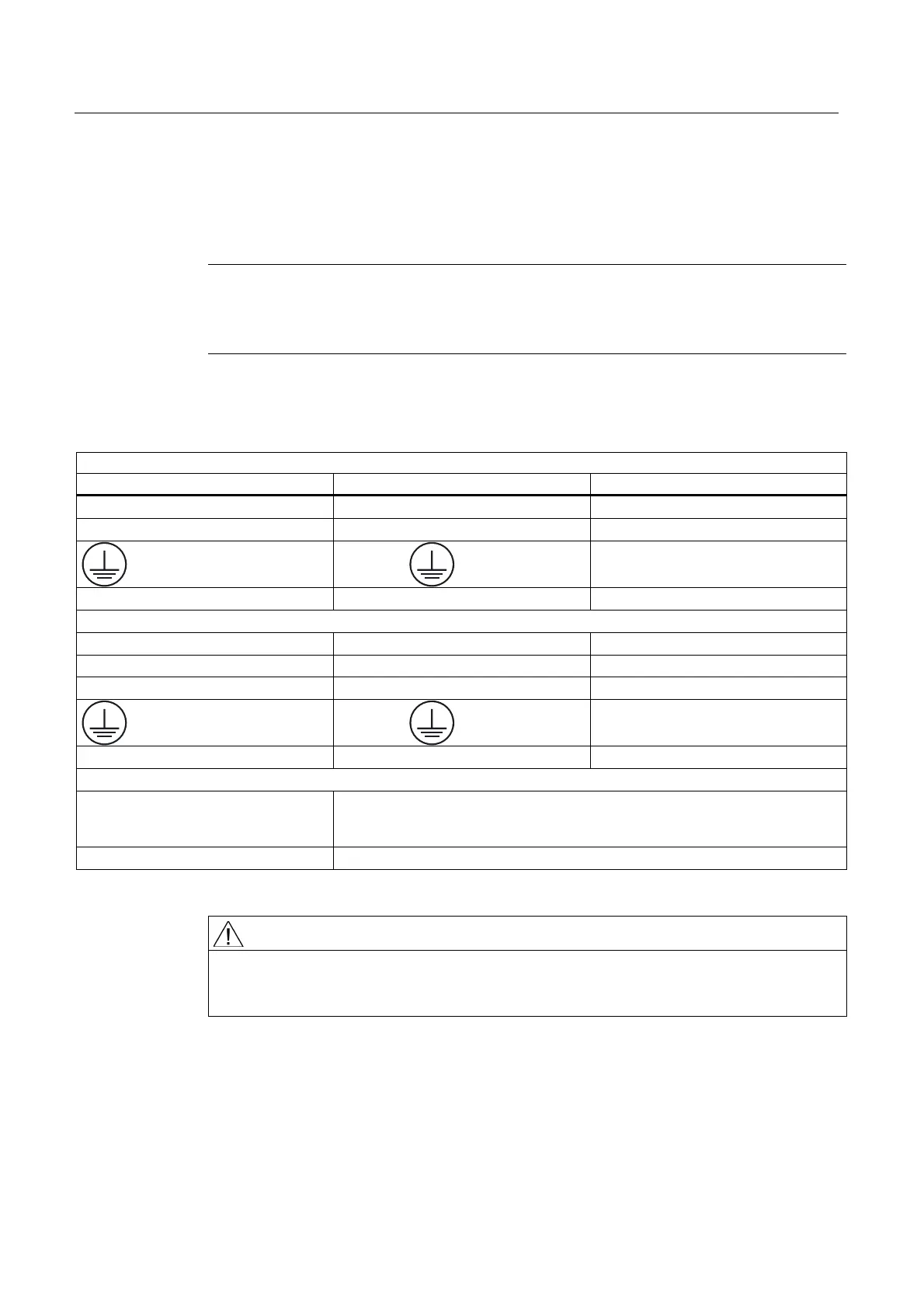

Table 3-36 Power terminals of braking modules 100 - 200 kW

DC link connection (via busbars, 100 - 200 kW)

Connection/significance Remarks Tightening torque [Nm]

C/L+ input (plus DC link) Busbar C/L+ 16

D/L- input (minus DC link) Busbar D/L 16

Protective conductor Busbar PE

16

Shield connection M6 bolts at top of housing 8

Braking resistor connection (via busbars, 100 - 200 kW)

Connection/significance. Remarks Tightening torque [Nm]

G/R+ external braking resistor Busbar G/R+ 16

H/R external braking resistor Busbar H/R 16

Protective conductor Busbar PE

16

Shield connection M6 bolts at bottom of housing 8

NOTE

Connection via Crimping cable lug to DIN 46234

With shrinkdown plastic tubing pulled over it

Cables connected with supplied M8 x 25 screws

AWG max 2/ 0

WARNING

The braking module can be connected to the DC link with or without fuses. The connections

between the converter and inverter and braking module must be short-circuit and ground-

fault resistant. The electric strength of the cable must be rated to the line voltage.

Fuses

● Fuses are required for multi-motor systems with a shared DC link (infeed power >>

power of the braking module).

● House-hold type MCBs (1000 V) must be installed in the plus and minus branches.

Loading...

Loading...