A.1 List of machine data

Machine and Setting Data 802D

A-218

SINUMERIK 802D sl Instruction Manual (BA), 05/2005 Edition

6FC5 397-0CP10-1BA0

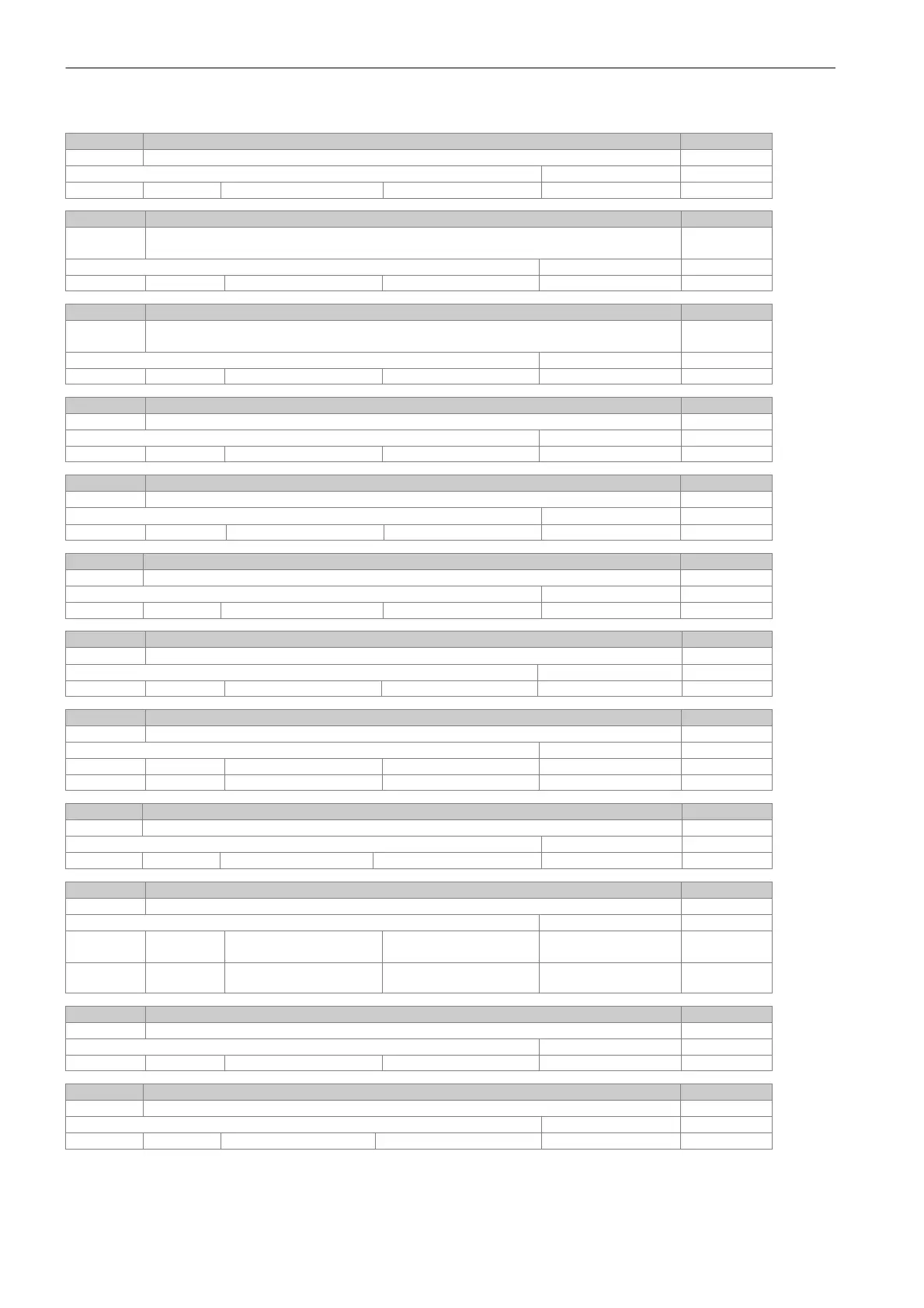

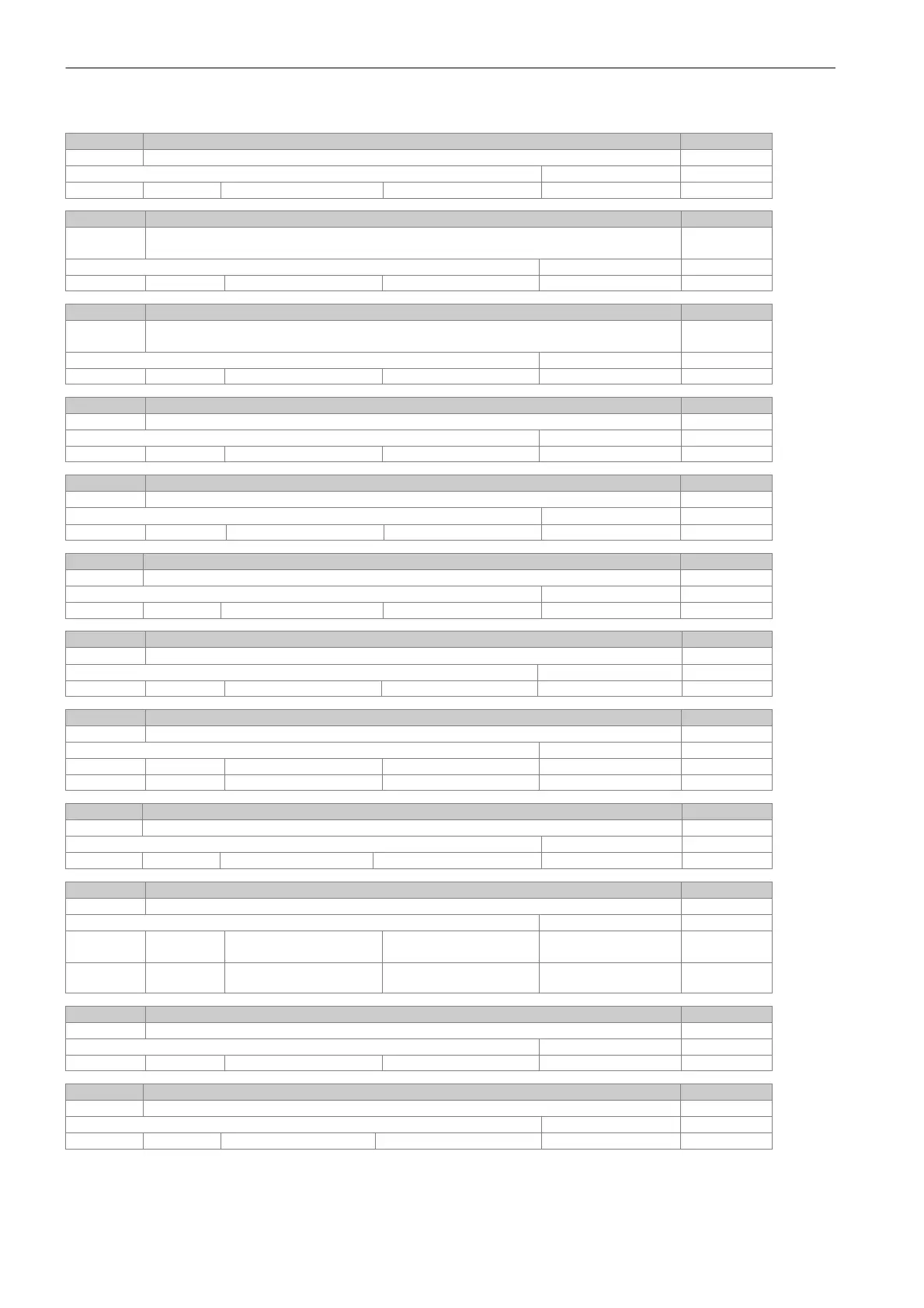

32510 FRICT_COMP_ADAPT_ENABLE

– Friction compensation adaptation active NEW CONF

EXP, – – BOOLEAN

Default 1 FALSE – – 2/2

32520 FRICT_COMP_CONST_MAX

mm/min,

rev/min

Maximum friction compensation value NEW CONF

EXP, – – DOUBLE

Default 1 0.0 – – 2/2

32530 FRICT_COMP_CONST_MIN

mm/min,

rev/min

Minimum friction compensation value NEW CONF

EXP, – – DOUBLE

Default 1 0.0 – – 2/2

32540 FRICT_COMP_TIME

s Friction compensation time constant NEW CONF

EXP, – – DOUBLE

Default 1 0.015 – – 2/2

32630 FFW_ACTIVATION_MODE

– Feedforward control can be activated from the program RESET

–, – CTEQ BYTE

Default – 1 – – 2/2

32640 STIFFNESS_CONTROL_ENABLE

– Dynamic stiffness control NEW CONF

–, – CTEQ BOOLEAN

Default 1 FALSE – – 2/2

32642 STIFFNESS_CONTROL_CONFIG

– Configure dynamic stiffness control POWER ON

–, – CTEQ BYTE

Default 1 0 0 1 2/2

32644 STIFFNESS_DELAY_TIME

s Dyn. stiffness control: Delay POWER ON

–, – CTEQ DOUBLE

Default 1 0.0 –0.02 0.02 7/2

plus – –0.0015 – – 2/2

32700 ENC_COMP_ENABLE

– Encoder/lead error compensation NEW CONF

– – BOOLEAN

Default 1 FALSE – – 2/2

32810 EQUIV_SPEEDCTRL_TIME

s Equivalent time constant for the speed control loop NEW CONF

–, – – DOUBLE

Default 6 0.008, 0.008, 0.008, 0.008,

0.008, 0.008

– – 7/2

plus – 0.003, 0.003, 0.003, 0.003,

0.003, 0.003

– – 2/2

33050 LUBRICATION_DIST

mm, degr. Travel for the lubrication pulse PLC signal NEW CONF

–, – – DOUBLE

Default – 1.0e8 – – 3/3

34000 REFP_CAM_IS_ACTIVE

– Axis with reference point cam RESET

–, – – BOOLEAN

Default – TRUE – – 2/2

Loading...

Loading...