A.2 Setting data

Machine and Setting Data 802D

A-228

SINUMERIK 802D sl Instruction Manual (BA), 05/2005 Edition

6FC5 397-0CP10-1BA0

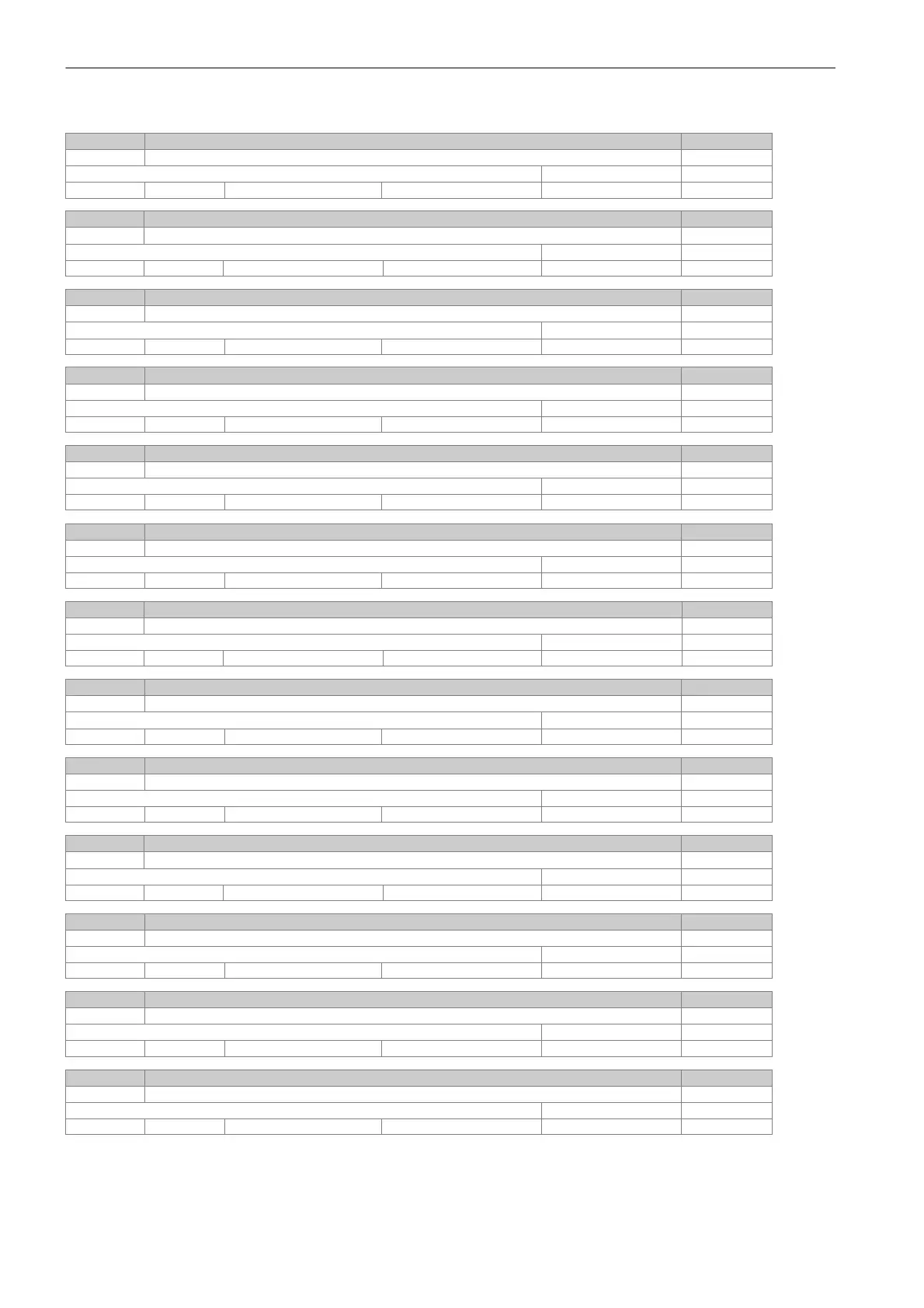

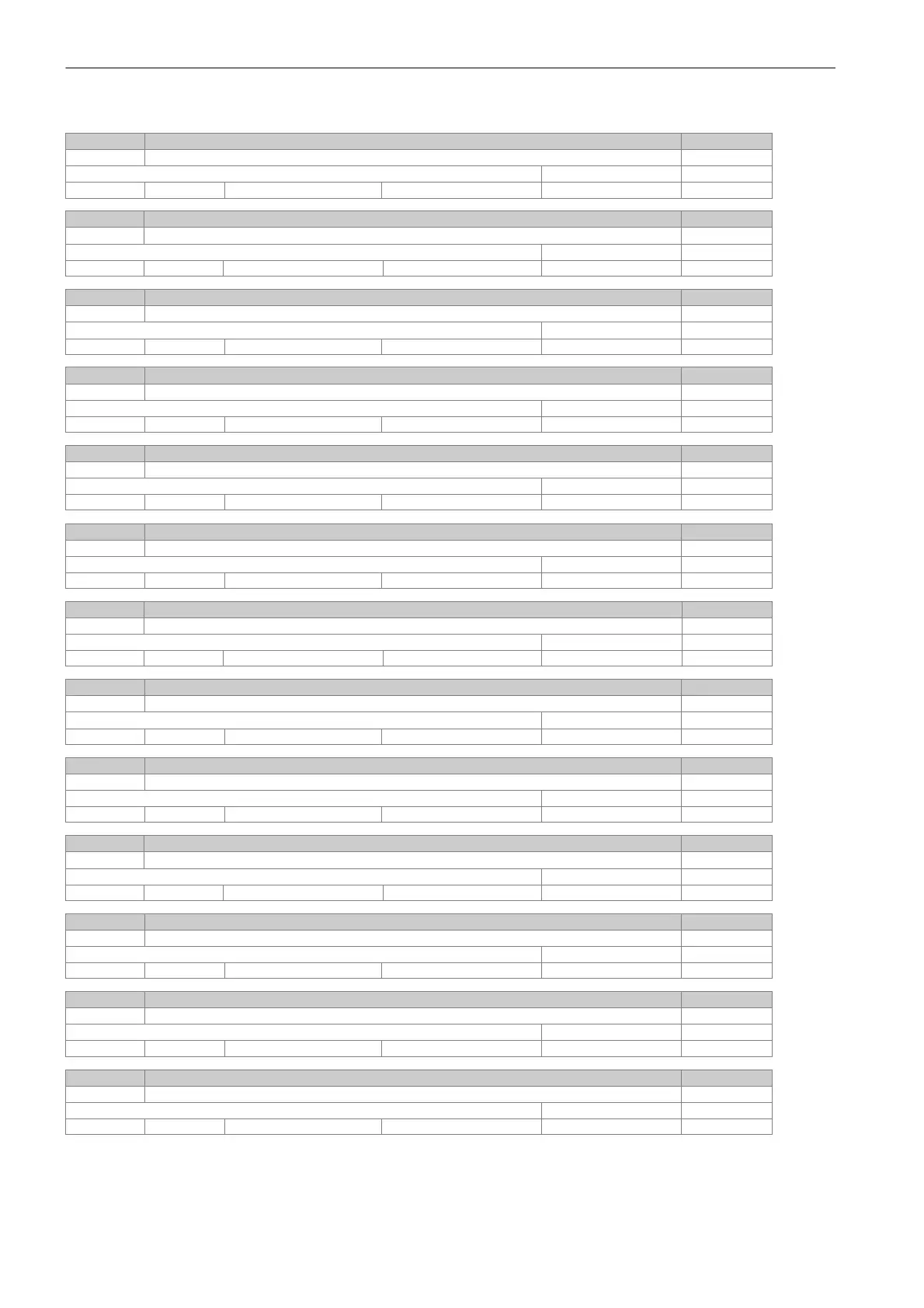

42528 CUTCOM_DECEL_LIMIT

– Feedrate reduction at circles with TRC IMMED.

– – DOUBLE

Default – 0. 0. 1. 7/7

42940 TOOL_LENGTH_CONST 0

– Tool length component when changing the plane IMMED.

– – DWORD

Default – 0 – – 3/3

42950 TOOL_LENGTH_TYPE

– Tool length component not depending on tool type IMMED.

– – DWORD

Default – 0 – – 3/3

42990 MAX_BLOCKS_IN_IPOBUFFER

– Max. number of blocks in the IPO buffer IMMED.

– – DWORD

Default – –1 – – 2/2

43120 DEFAULT_SCALE_FACTOR_AXIS

– Default scaling factor with active G51 IMMED.

– – DWORD

Default – 1 – – 7/7

43200 SPIND_S

rev/min Speed for spindle start through virtual interface IMMED.

– – DOUBLE

Default – 0.0 – – 7/7

43202 SPIND_CONSTCUT_S

m/min Cutting rate for spindle start through virtual interface IMMED.

– – DOUBLE

Default – 0.0 – – 7/7

43210 SPIND_MIN_VELO_G25

rev/min Limits the spindle speed to the specified minimum value IMMED.

– – DOUBLE

Default – 0.0 – – 7/7

43220 SPIND_MAX_VELO_G26

rev/min Limits the spindle speed to the specified maximum value IMMED.

– – DOUBLE

Default – 1000.0 – – 7/7

43230 SPIND_MAX_VELO_LIMS

rev/min Limits the spindle speed to the specified maximum value with G96, G691, G97 IMMED.

– – DOUBLE

Default – 100.0 – – 7/7

43240 M19_SPOS

degrees Spindle position with M19 IMMED.

–, – – DOUBLE

Default – 0.0 –10000000.0 10000000.0 7/7

43250 M19_SPOSMODE

– Approach mode for spindle position with M19 IMMED.

–, – – DWORD

Default – 0 0 5 7/7

43340 EXTERN_REF_POSITION_G30_1

– Reference point position for G30.1 IMMED.

–, – – DOUBLE

Default – 0.0 – – 7/7

Loading...

Loading...