Installation and Setup 25

2005995 Rev O – 210712

Installation and Setup

General Recommendations

Material Handling

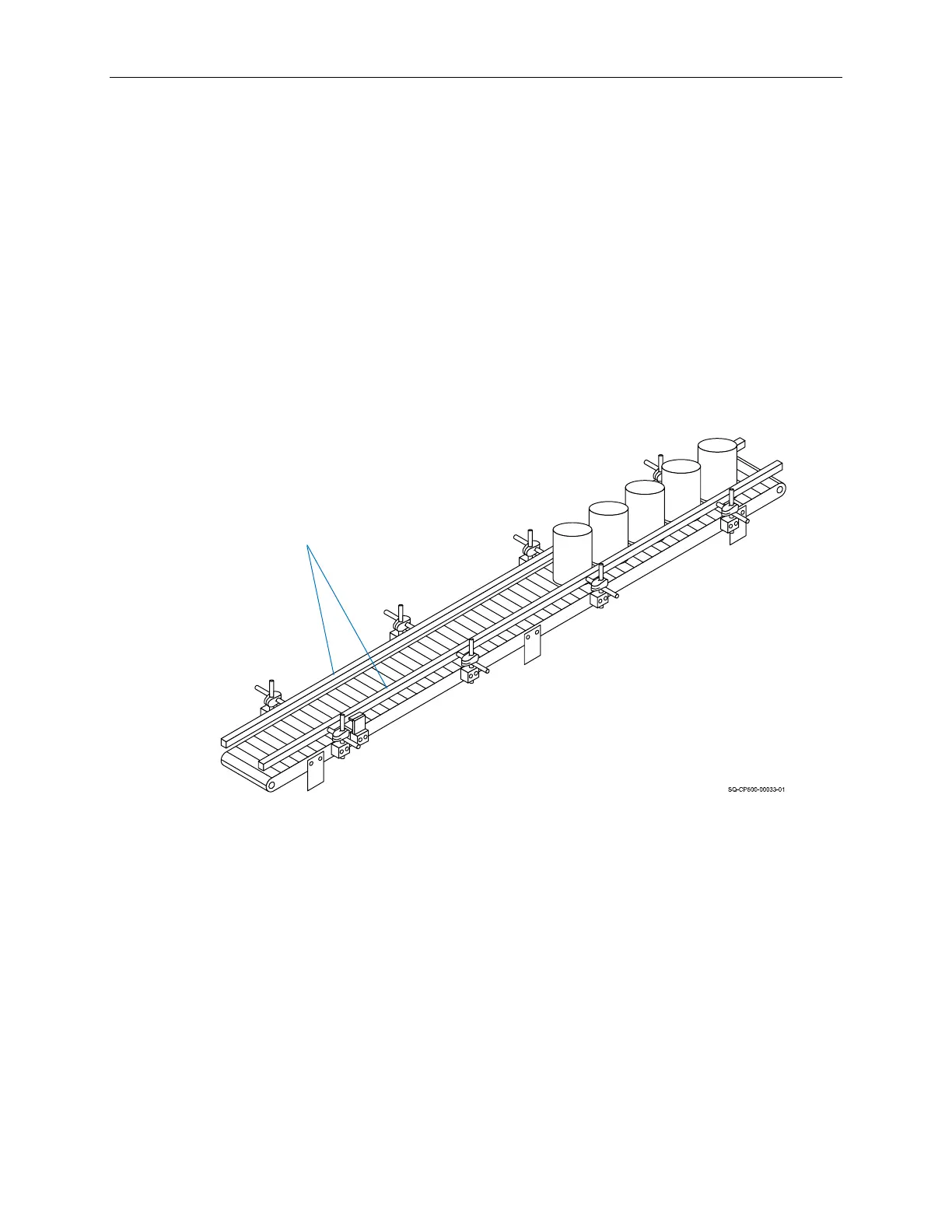

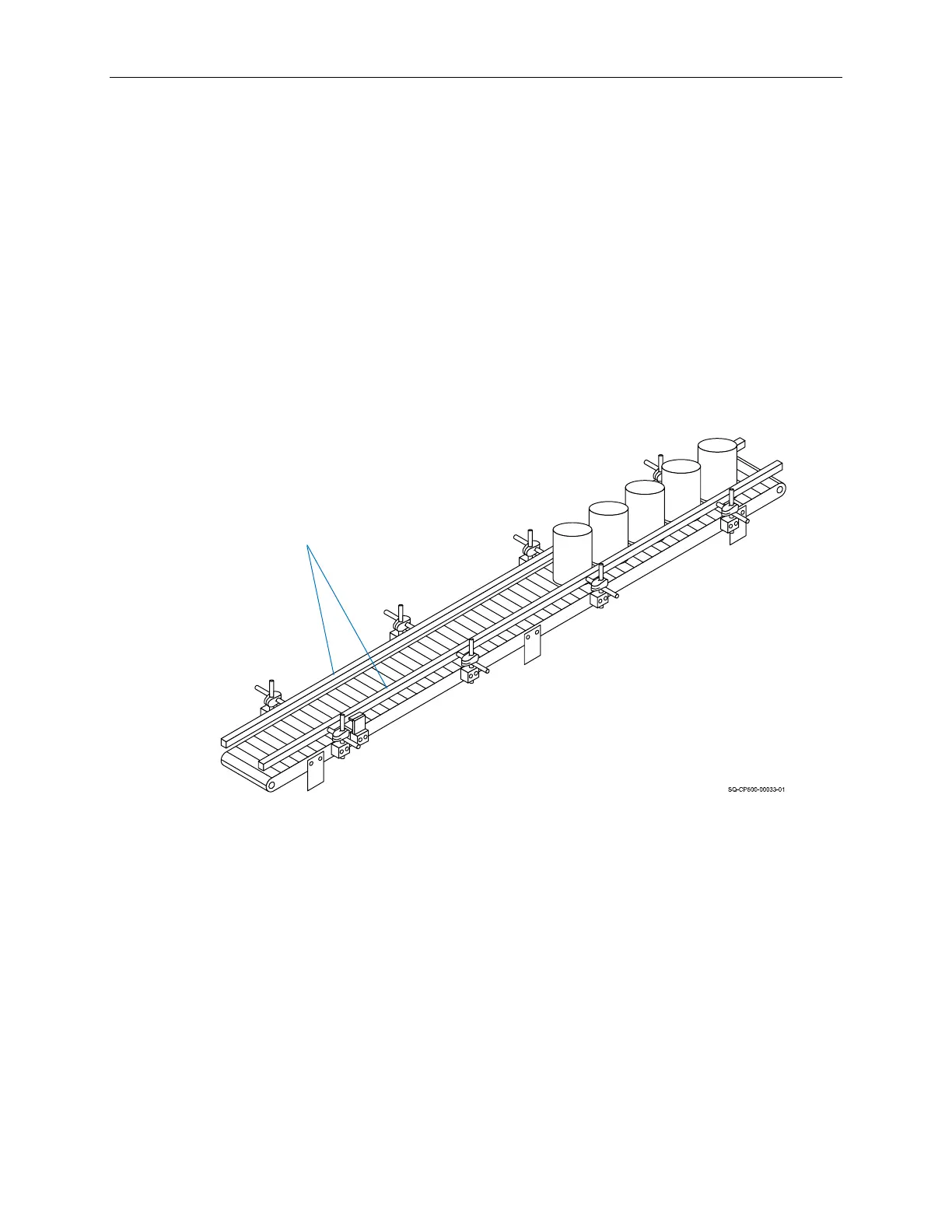

The most critical item for consistently superior quality printing is material handling. This is an

area controlled by the customer and the installer. Always use adequate Conveyor Product

Guides, and ensure that they are installed and maintained properly. Incorrect or inconsistent

product handling will cause print quality problems, maintenance problems, and could lead to

Printhead damage. The customer is responsible for maintaining proper material handling

equipment.

Grounding

Always ensure that the power source is properly grounded before using. To further improve

print quality and protect the system from static electricity, install a 0.25" (or wider) Ground

Braid (Part Number 2005024) between the Printhead Controller and earth ground.

AC Power

In some locations where the printing system is installed, AC power may be subject to line

noise, brownouts, and blackouts. If line noise, brownouts, or blackouts occur on a regular

basis, a good-quality line conditioner or Uninterruptible Power Supply (Part Number

2004199) should be installed to ensure data integrity. In many cases, these devices may not

be necessary; it is acceptable to start an installation without them. However, if system

lockups or occasional distorted print occurs, the first corrective measure should be to isolate

and clean up the AC power.

Properly Installed and Maintained

Conveyor Guides

Conveyor

Guides

Loading...

Loading...