1D-59 Power Unit Mechanical:

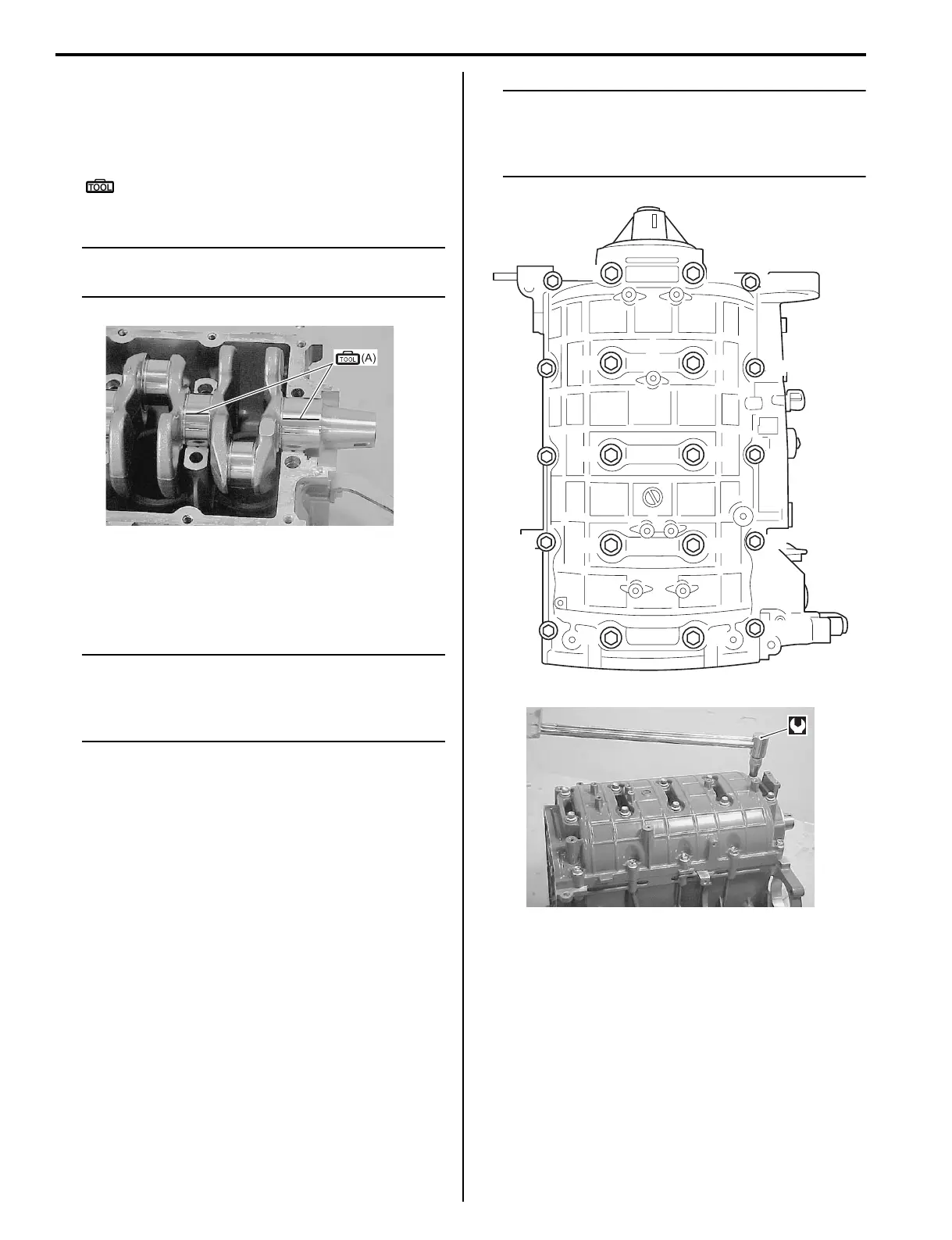

3) Install crankshaft to cylinder.

4) Place a piece of Plastigauge across full width of

bearing (parallel to crankshaft) on journal.

Do not place Plastigauge over oil hole.

Special tool

(A): 09900–22301 (Plastigauge (0.025 –

0.076 mm))

NOTE

Do not rotate crankshaft while Plastigauge is

installed.

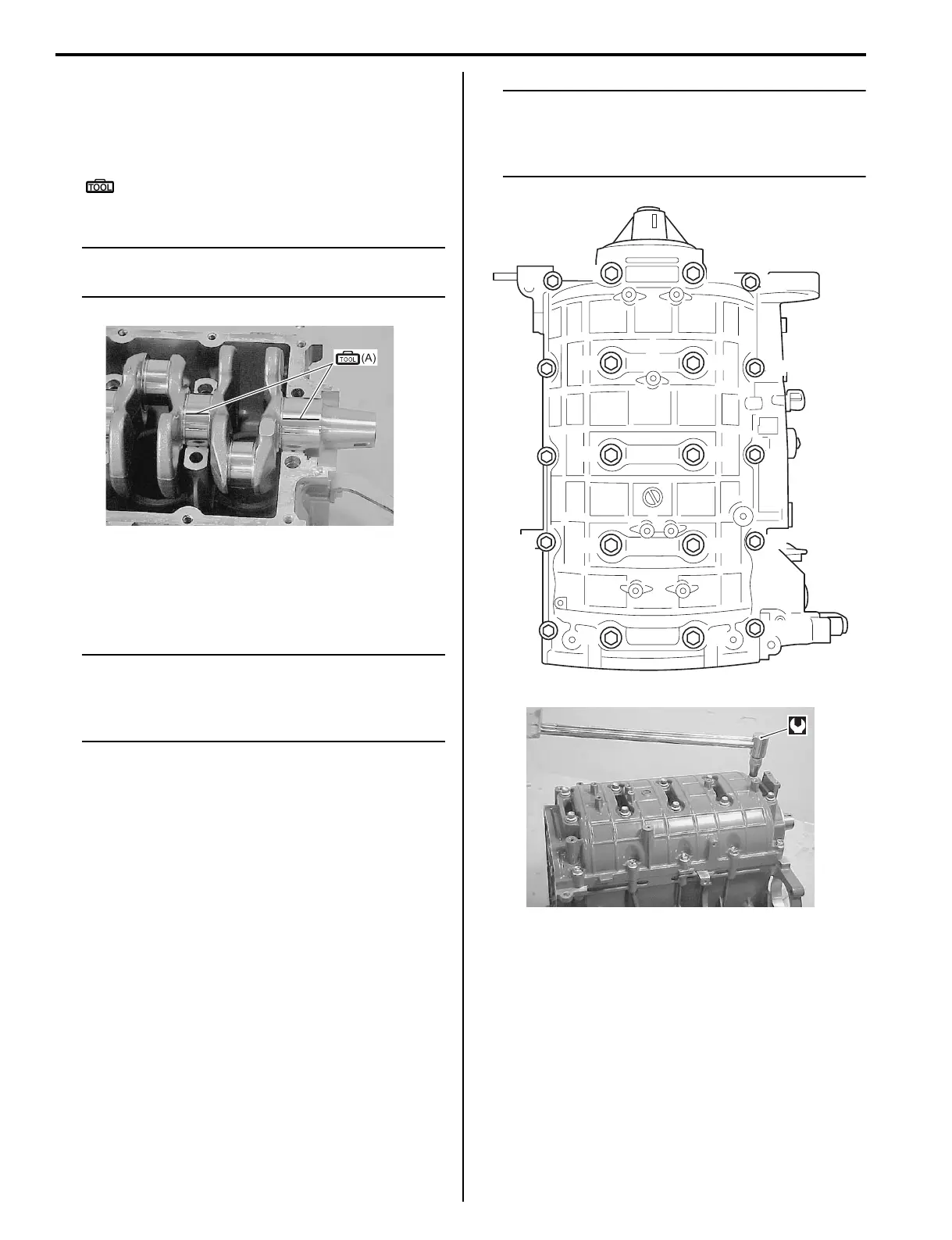

5) Assemble crankcase to cylinder.

6) Apply engine oil to crankcase bolts.

Tighten crankcase bolts in three steps following the

order indicated below.

NOTE

Tighten 10 mm (0.394 in.) thread diameter

bolts first (following the order shown in

figure), then tighten 8 mm (0.315 in.) thread

diameter bolts.

Tightening torque

Crankcase inside bolt (10 mm thread diameter)

[1st step]: 11 N·m (1.1 kgf-m, 8.0 lbf-ft)

Crankcase inside bolt (10 mm thread diameter)

[2nd step]: 45 N·m (4.5 kgf-m, 32.5 lbf-ft)

Crankcase inside bolt (10 mm thread diameter)

[Final step]: 52 N·m (5.2 kgf-m, 37.5 lbf-ft)

Tightening torque

Crankcase outside bolt (8 mm thread diameter)

[1st step]: 6 N·m (0.6 kgf-m, 4.3 lbf-ft)

Crankcase outside bolt (8 mm thread diameter)

[2nd step]: 21 N·m (2.1 kgf-m, 15.0 lbf-ft)

Crankcase outside bolt (8 mm thread diameter)

[Final step]: 25 N·m (2.5 kgf-m, 18.1 lbf-ft)

NOTE

Crankcase must be torqued to specification

in order to assure proper compression of

plastigauge and accurate reading of

clearance.

7) Remove crankcase from cylinder.

I9J011140261-02

“9”

“6”

“2”

“4”

“8”

“5”

“9”

“6”

“2”

“4”

“8”

“5”

“1”

“1”

“3”

“3”

“7”

“7”

“10”

“10”

I9J011140018-03

I9J011140262-01

Loading...

Loading...