5-74 4203780 First Edition

HYDROSTATIC POWER TRAIN

5

1. Remove both drive axle reducer assemblies. (See

“Drive Axle Reducer Assembly” on page 5-69.)

2. Remove the input bevel pinon assembly. (See “Input

Bevel Pinion Assembly” on page 5-65.)

NOTES

Remove the breather (3), plugs (10), drain plug (16), and

seal (15) only if replacement is required.

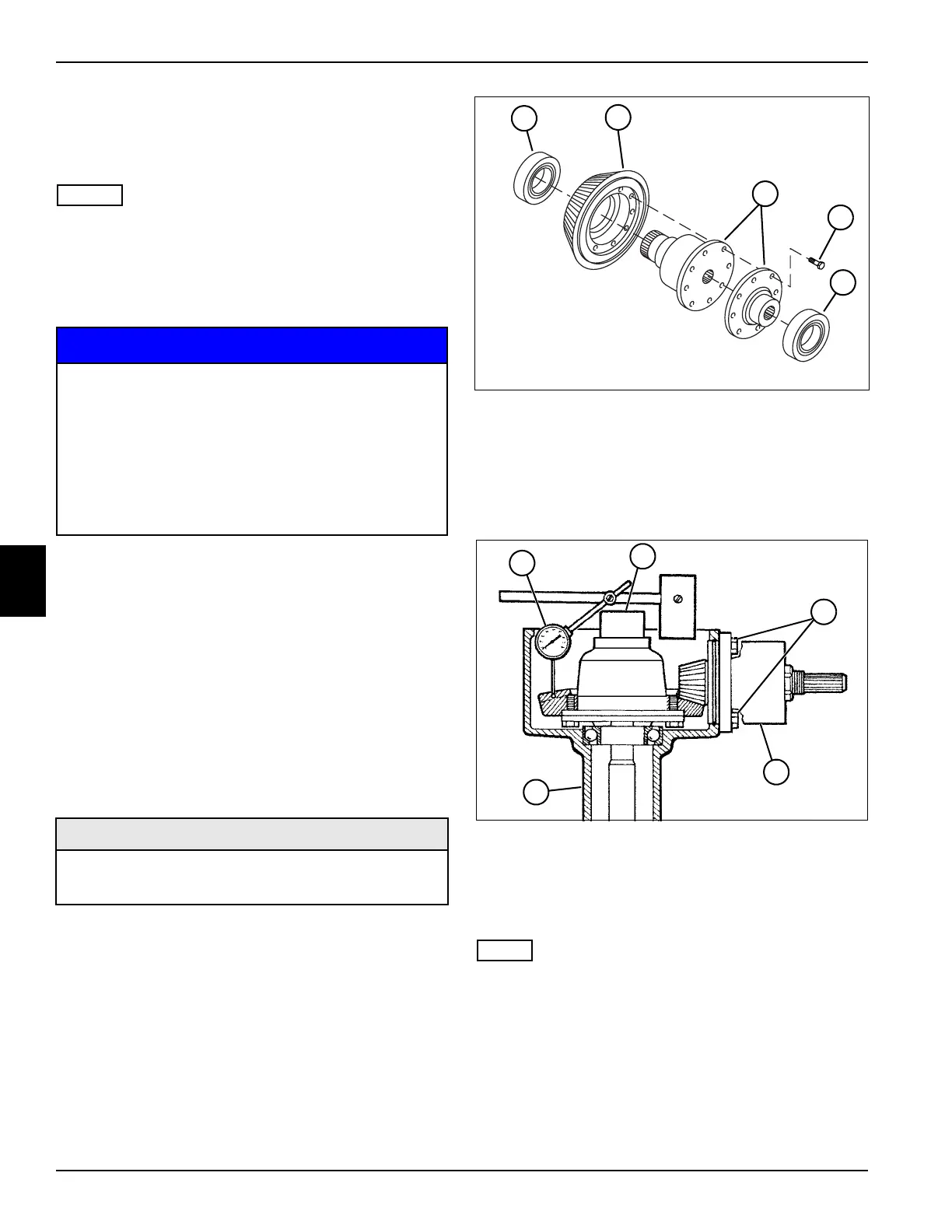

3. Disassemble the differential assembly as shown.

4. Place parts in assembly order on a clean work area

as they are removed.

NOTICE

Inspection Notes

• Keeping parts in assembly order, clean and air dry

each item for inspection.

• If replacing the ring gear, the pinion shaft must also

be replaced. These parts are a matched set.

• Inspect for worn or defective parts.

• Inspect all parts for cracks, nicks, burrs, and

excessive wear. Inspect for scoring, galling, and

scratches on surfaces. Replace parts as necessary.

Assembly

See Figures 5-81 through 5-83.

Figure 5-81

1. Assemble the differential (3) and ring gear (2) using

eight hex head bolts (4). Apply Loctite 242 to hex

head bolts (4) before assembly. Install hex head bolts

and tighten to 37 lb-ft (51 N·m).

2. Press ball bearings (1) onto the differential assembly.

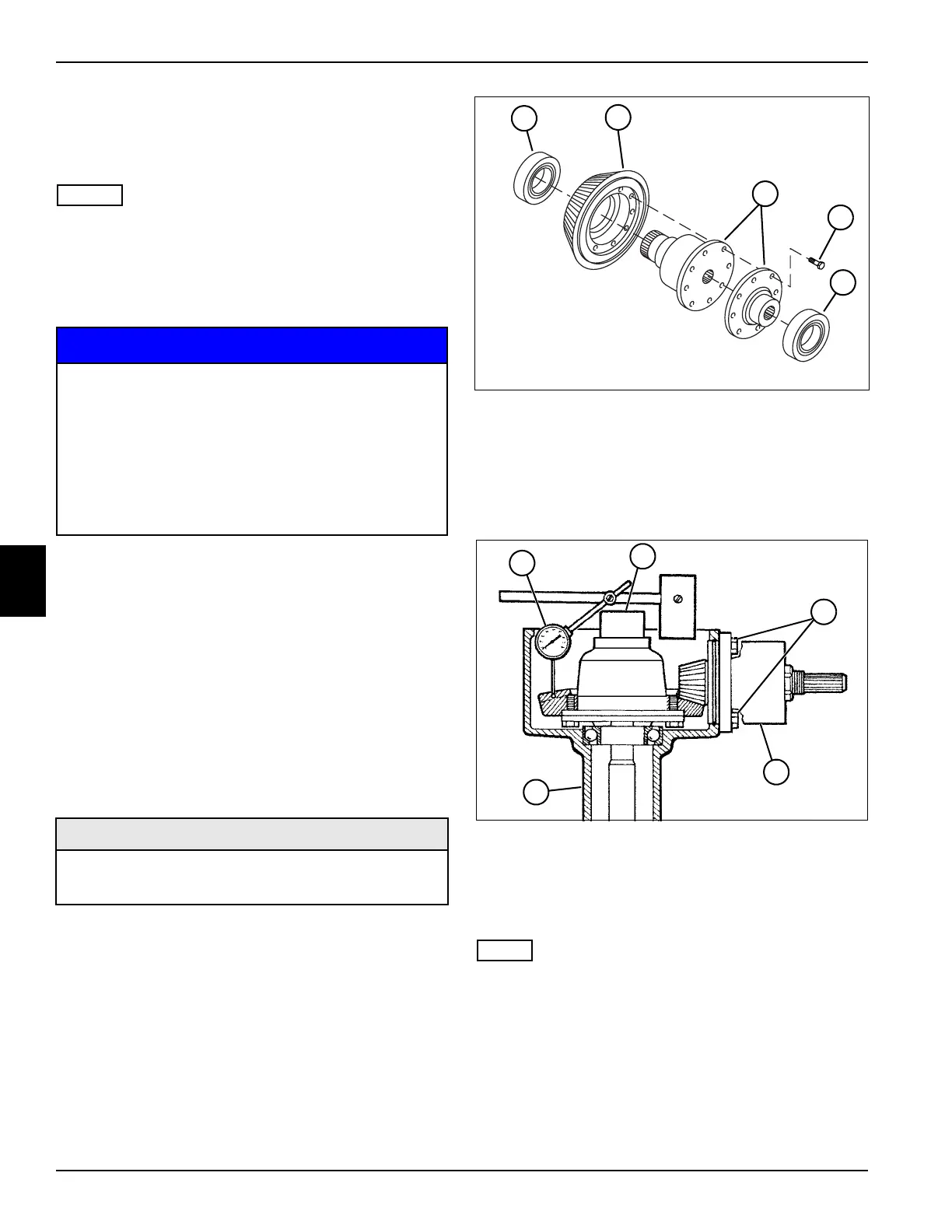

Figure 5-82

3. Install the differential assembly (6) in the left

differential housing (9). Do not install shims at this

time. Make sure the differential assembly is fully

seated in the bearing bore.

NOTE

Do not apply Loctite to the input bevel pinion housing

bolts at this time.

4. Install input bevel pinion assembly (8). (See

“Assembly” on page 5-67.)

5. Using a dial indicator (5) against the pinion tooth,

check the gear backlash.

6. Subtract 0.008 in. (0.2 mm) from the measurement

obtained. Build a shim pack equal to the final

dimension.

• It is important that parts are marked and

placed in assembly order to aid in assembly.

• It is important that all parts are absolutely

clean, as contamination can result in serious

damage and/or improper operation.

• Never use shop towels or rags to dry parts

after cleaning, as lint may clog passages. Dry

parts using compressed air.

Required Materials

•Loctite

®

Primer

•Loctite

®

518 Gasket Eliminator

TN1932

1

3

4

1

2

TN1933

9

8

5

6

7

Loading...

Loading...