HYDRAULICS

4203781 First Edition 6-47

6

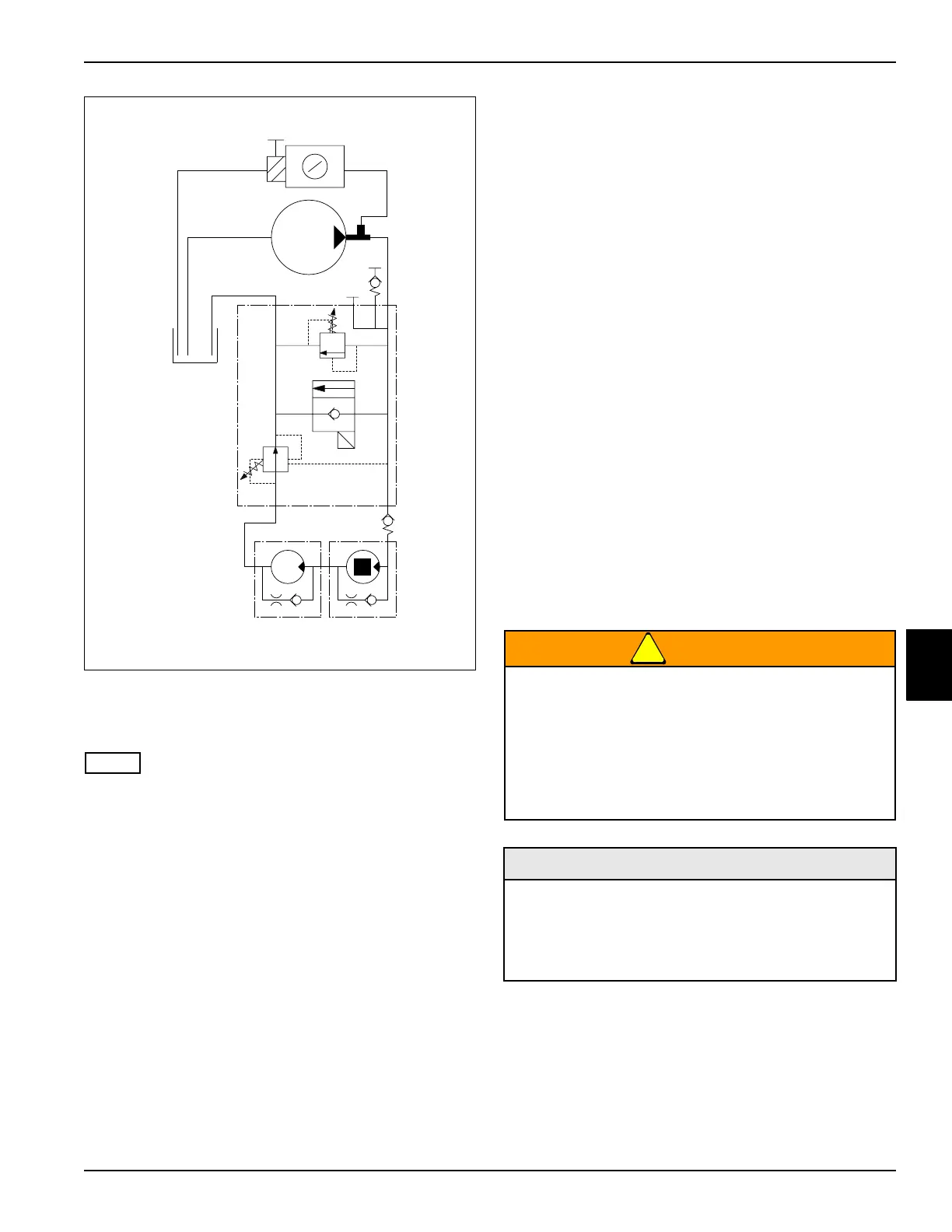

Figure 6-45: Left Wing Cutting Unit Circuit Test—

Inside Cutting Unit Motor Blocked

9. Bypass seat switch and set park brake.

NOTE

Verify engine rpm is within specification (2800 rpm ± 50)

to ensure accurate hydraulic test results.

10. Start engine and run at full throttle (2800 rpm ± 50).

11. Use the flow meter to warm the hydraulic oil. Turn the

flow meter valve (4) until a reading of 1500 psi (103

bar) or one half of the relief valve rating is reached.

Warm oil to 120–150° F (49–65° C); open valve fully

after operating temperature is reached.

12. Enable wing mower deck switch and engage PTO

switch.

13. Read and record the left wing cutting unit circuit no

load flow.

14. Slowly close flow meter valve (4) until pressure

reaches 2250 psi (155 bar). Read and record the left

wing cutting unit circuit loaded flow.

15. Open flow meter valve (4), disengage switches, and

stop engine.

16. Calculate left wing cutting unit circuit leakage.

(Step 13 – Step 14 / Step 13 x 100 = Leak

Percentage)

Is left wing cutting unit circuit leakage 10% or

less?

YES The left wing cutting unit circuit is good.

Proceed to “Left Wing Cutting Unit Motors

Test” on page 6-52.

NO Proceed to next question.

Is left wing cutting unit circuit leakage 11% to

20%?

YES The left wing cutting unit circuit is marginal.

Additional testing is required. Proceed to

“Left Wing Cutting Unit Pump Test” on

page 6-47.

NO Proceed to next question.

Is left wing cutting unit circuit leakage 21% or

more?

YES Test individual components in left wing

cutting unit circuit for leakage. Proceed to

“Left Wing Cutting Unit Pump Test” on

page 6-47.

Left Wing Cutting Unit Pump Test

See Figures 6-46 through 6-48.

!

WARNING

1. Park the mower safely. (See “Park Mower Safely” on

page 1-6.)

2. Before performing this test, perform left wing cutting

unit circuit test, leaving flow meter connected as

outlined.

TN2250

The hydraulic system is under pressure, and the

oil will be hot.

• Always relieve pressure in the hydraulic

system before performing service.

• Failure to follow appropriate safety

precautions may result in death or serious

injury.

Required Tools and Materials

• Flow Meter

• -10 ORFS Test Hose 3600 psi (207 bar)

• -10 ORFS Tee Fitting

• -10 ORFS Blocking Disk

Loading...

Loading...