5-24 673831-Rev A

HYDROSTATIC POWER TRAIN

5

Field Test Procedures

When a hydraulic system failure occurs, some simple

effective tests can be performed prior to using a test

instrument. The results of these tests can lead you to the

suspected component failure. More extensive test

procedures, using test instruments, are presented later in

this section. (See “Instrument Test Procedures” on

page 5-25.)

Preliminary Checks

Perform the following checks prior to beginning any tests.

1. Check the hydraulic oil reservoir for proper fluid level,

the presence of air or water, and unusual odor.

2. Check all lines and fittings for leaks. Tighten as

needed.

3. Eliminate all mechanical issues prior to starting

hydraulic tests.

Charge Pump Test

The charge pump supplies oil for charging the traction

circuit and traction pump.

If faults exist in the charge pump, proceed with an

instrument test for the charge pump. (See “Charge Pump

Test” on page 5-26.)

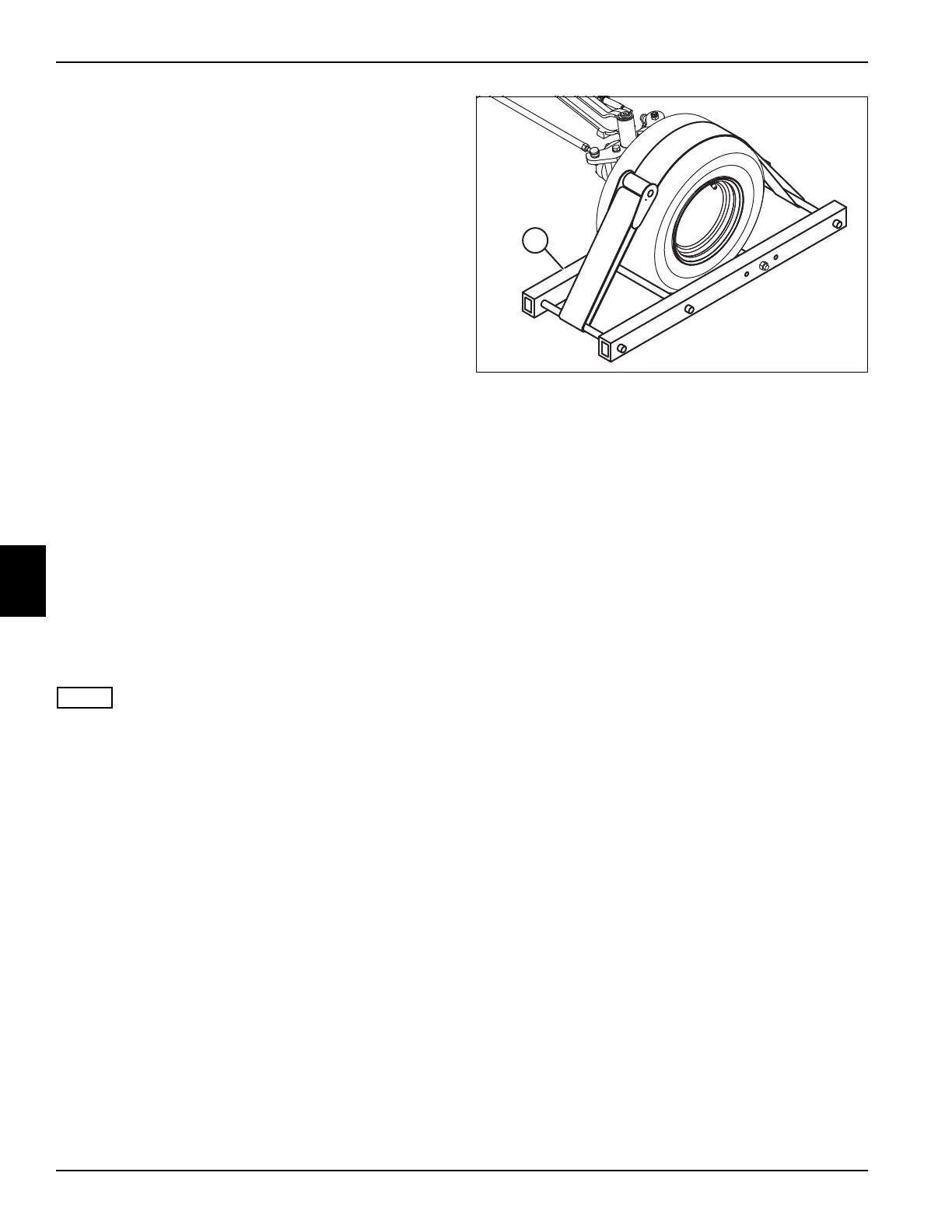

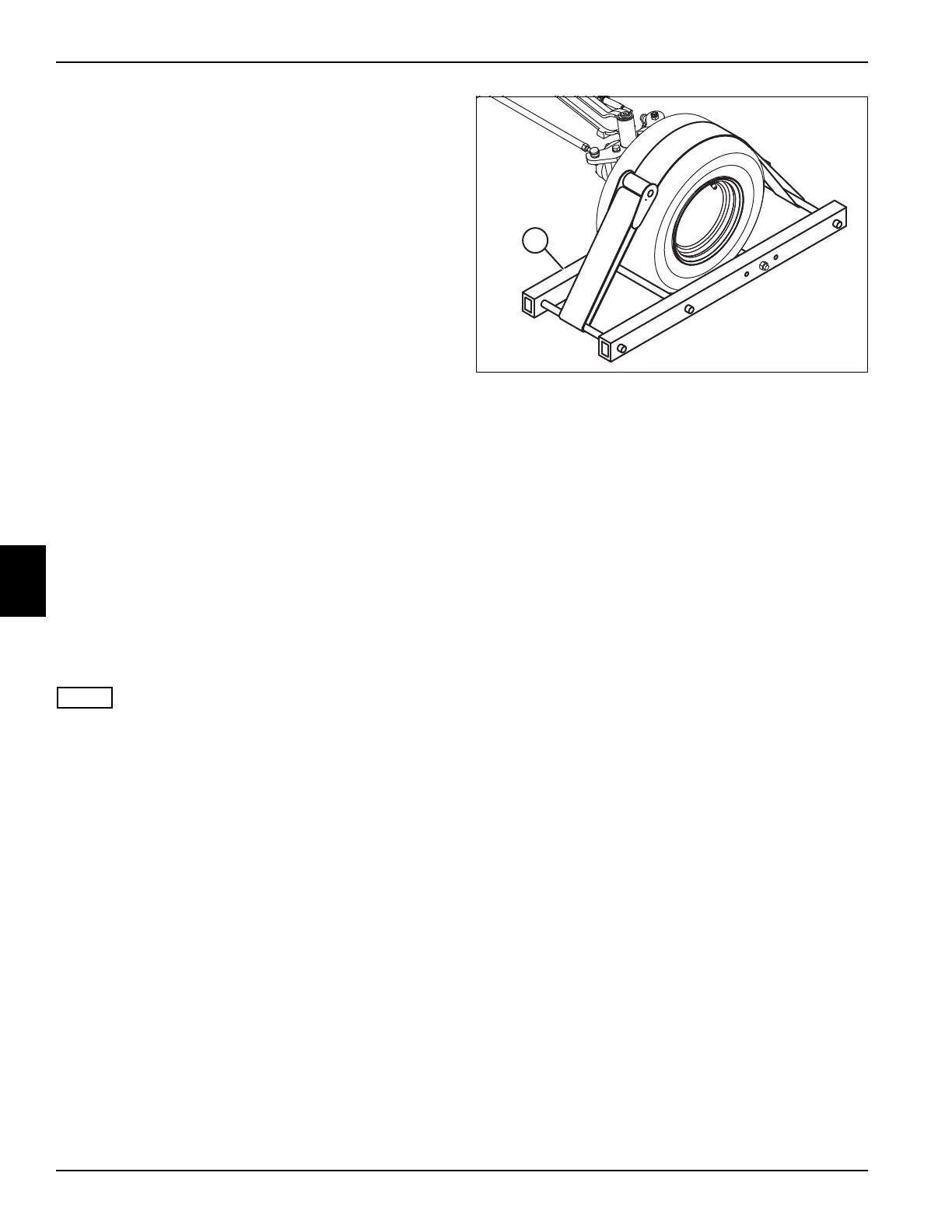

Traction System Test

See Figure 5-14.

• Be sure tow valve is closed before beginning traction

system test.

• The LDU will display a fault when the traction pedal is

pressed with the parking brake switch in the ON

position.

1. Operate hydraulic system until oil temperature is at

120–150° F (49–65° C).

2. Put the parking brake switch in the ON position.

Figure 5-14

3. Install wheel restraints (1) to all wheels.

4. Lower the cutting units and move throttle lever to full

throttle. Slowly push the traction pedal forward.

Does the engine labor or stall?

YES The hydrostatic drive train circuit is good.

NO The hydrostatic drive circuit is faulty.

Additional testing is required. Proceed to

instrument test. (See “Instrument Test

Procedures” on page 5-25.)

Loading...

Loading...