STEERING

673831-Rev A 7-21

7

Assembly Notes

• Assemble the steering cylinder by reversing the order

of disassembly.

• Lubricate all parts with clean hydraulic oil before

assembly.

• Always install new seals and O-rings for assembly;

used parts may leak.

• Check hydraulic oil level. Add oil as needed.

• Start the machine and check for hydraulic leaks and

cylinder operation. Repair as necessary.

• Check steering toe-in adjustment. (See “Tie Rod

Adjustment” on page 7-4.)

4WD Option Steering Cylinder

Removal and Installation

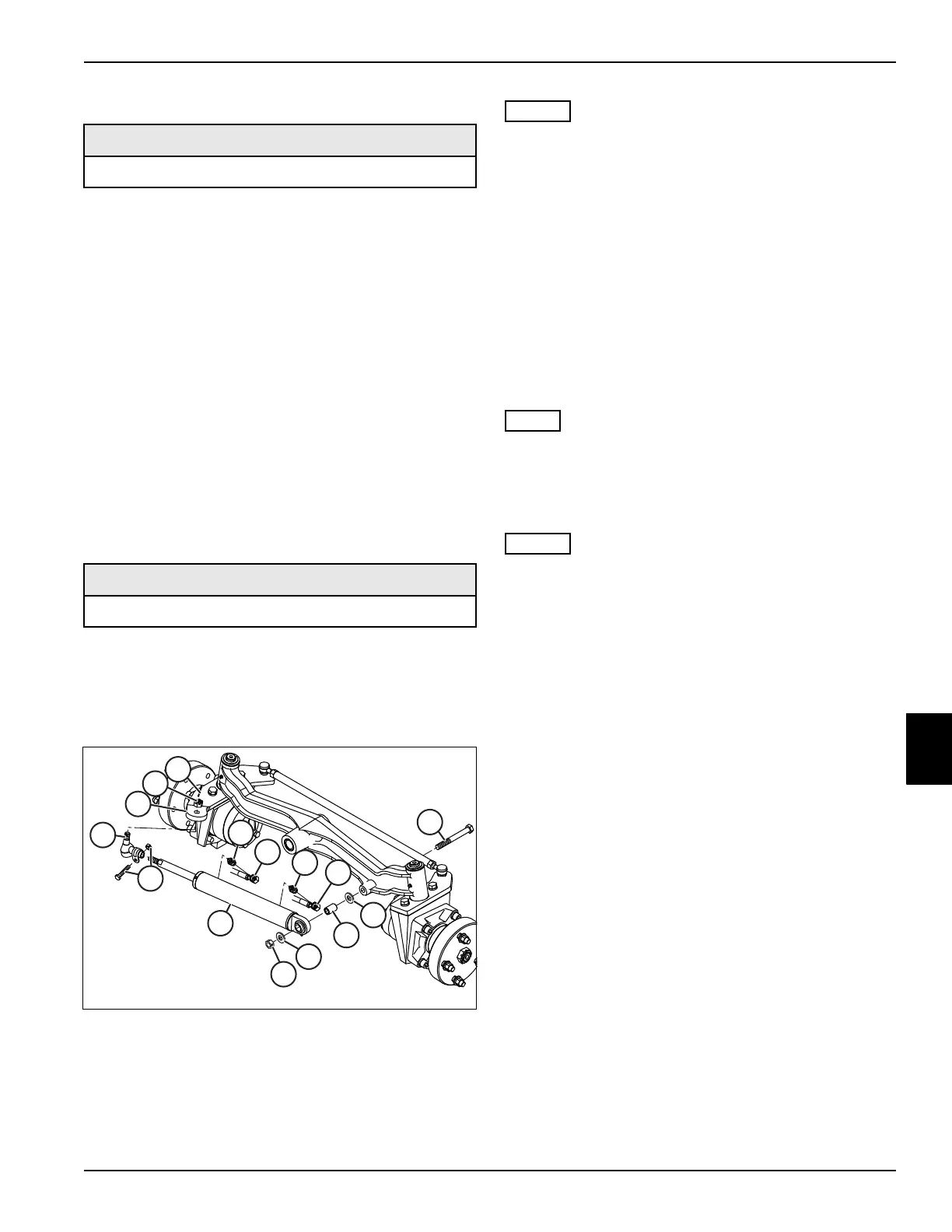

See Figures 7-28.

1. Park the mower safely. (See “Park Mower Safely” on

page 1-6.)

2. Thoroughly clean the area surrounding the steering

cylinder, especially the hydraulic hose fittings.

Figure 7-28

• Label all hydraulic hoses and record their locations to

ensure correct installation.

• Plug hydraulic hoses after disconnecting to prevent

loss of hydraulic oil.

3. Disconnect hydraulic hoses (1 and 2) from steering

cylinder (11). Remove fittings (3).

4. Remove screw (4), washers (5), spacer (6) and

center lock nut (7).

5. Support the steering cylinder (8).

6. Remove cotter pin (9) and nut (10). Using a ball joint

removal tool, remove the ball joint (11) from the

steering arm. Remove the steering cylinder (8) from

the steering arm (12).

Record the number of turns required to remove rod end

from steering cylinder.

7. Loosen clamp hardware (13) and remove ball joint

(11) from steering cylinder (8).

Installation Notes

• Install the steering cylinder by reversing the order of

removal.

• Inspect all ball joints for wear or torn dust seals.

• Using information recorded during disassembly,

install ball joint (11) onto steering cylinder (8) with the

correct number of turns.

• Before installing the steering cylinder assembly,

verify that the ball joint taper and the mating tapered

surfaces in the steering arm are free of burrs, dirt,

and debris. DO NOT apply lubricant of any kind to

these surfaces.

• Tighten castle nut (10) to 40-55 lb-ft (54-75 N·m).

Adjust (tighten) nut as needed to align the slots with

the hole in the rod ends.

• Always install new cotter pins (9).

• Tighten fittings (3) to 15 lb–ft (19 N·m).

• Tighten hoses (1 and 2) to 11 lb–ft (15 N·m).

• Check hydraulic oil level. Add oil as needed.

• Start the machine and check for hydraulic leaks and

cylinder operation. Repair as necessary.

• Check steering toe-in adjustment. (See “Tie Rod

Adjustment” on page 7-4.)

Required Materials

Seal Kit (Jacobsen PN TBD)

Required Tools or Equipment

Ball Joint Removal Tool

Loading...

Loading...