7-22 673831-Rev A

STEERING

7

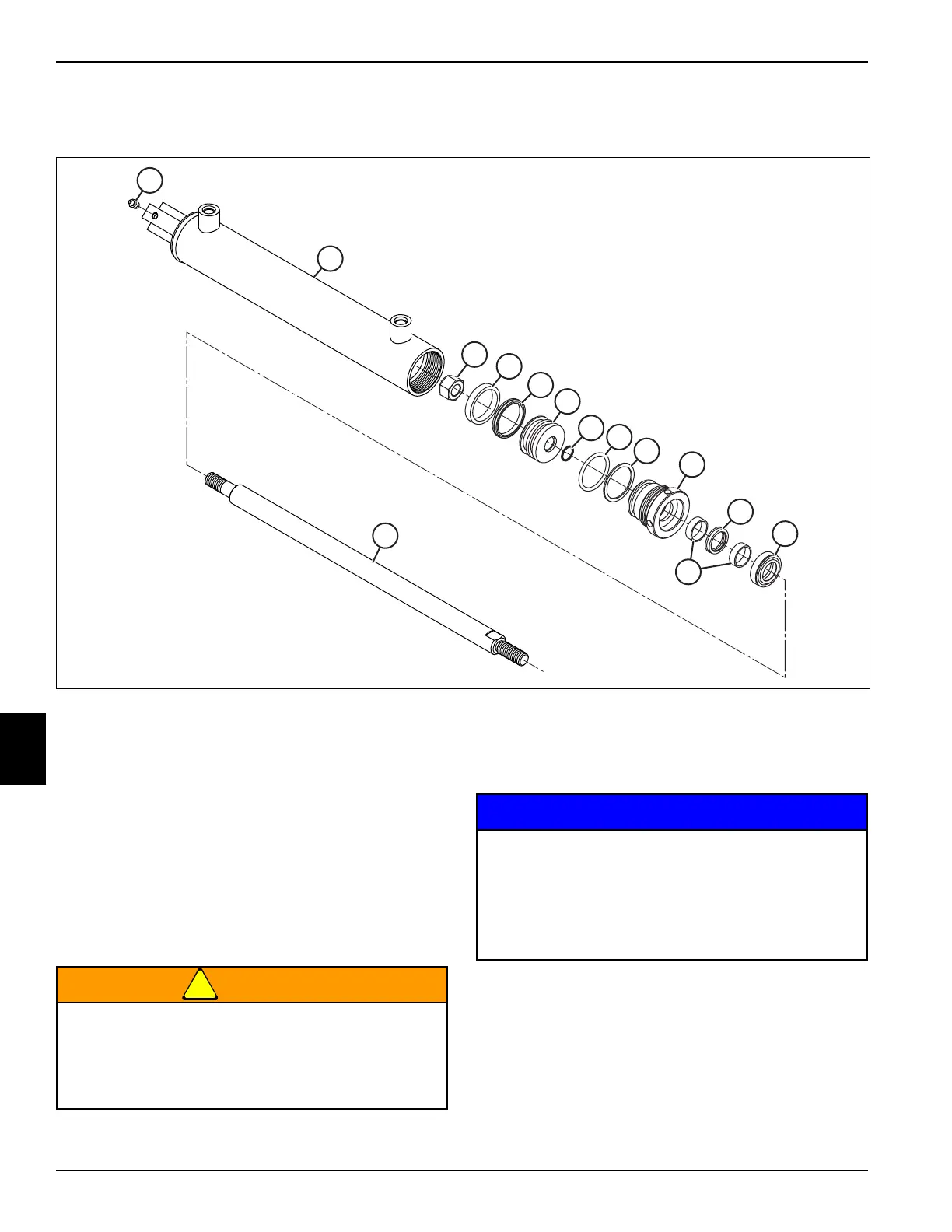

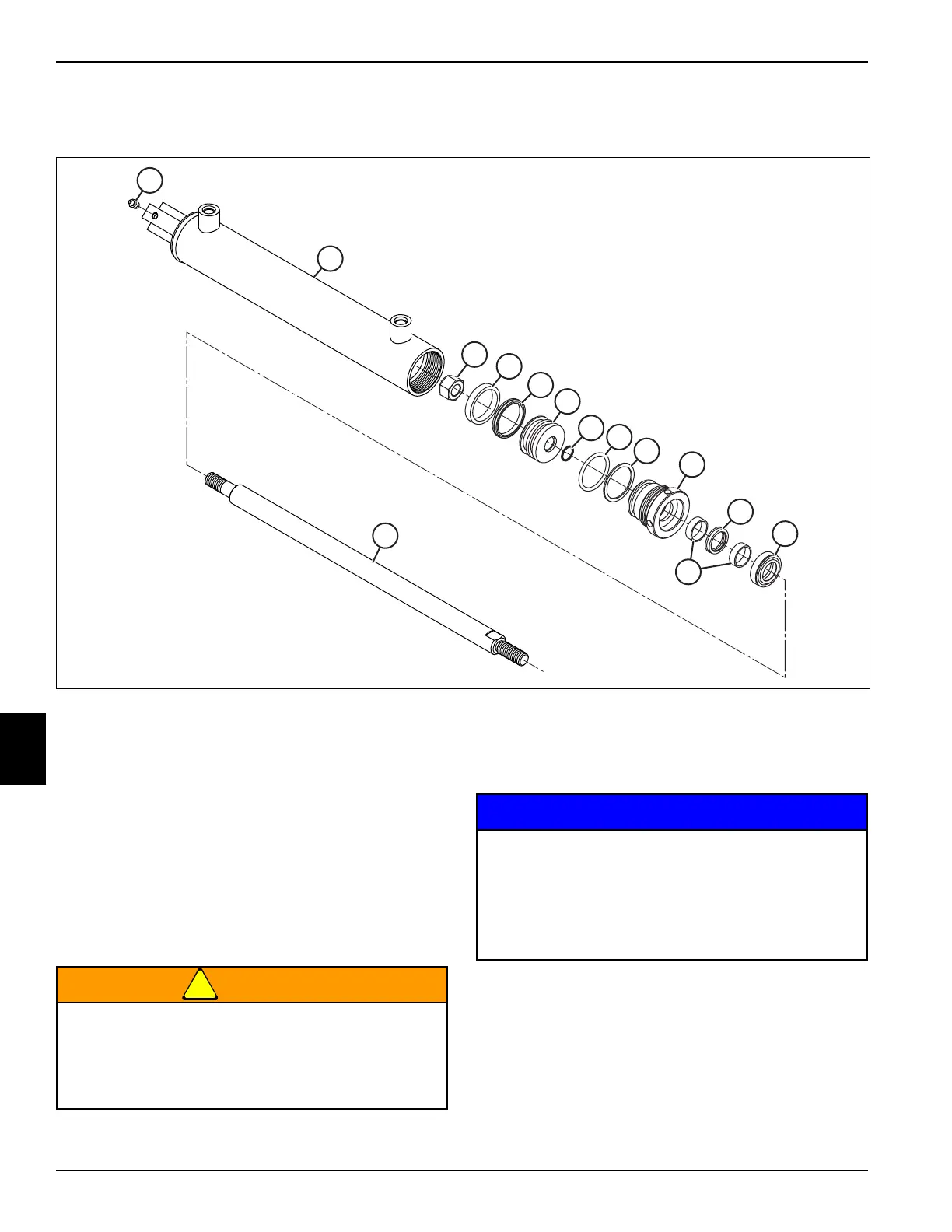

Disassembly, Inspection, and Assembly

See Figure 7-29.

Figure 7-29

1. Remove the gland (7 through 12) from barrel (1).

2. Remove the piston and rod assembly (2 through 6)

from barrel (1).

3. Remove nut (6), piston assembly (2, 4 and 5), and

O-ring (3) from rod (13).

4. Remove seal (4) and wear ring (5) from piston (2).

5. Remove O-ring (8), back-up ring (9), wear rings (10)

rod seal (11), and rod wiper (12) from gland (7).

6. Clean all parts using clean solvent, and dry using

compressed air.

7. Inspect all parts for excessive wear, cracks, broken

parts, and damaged threads.

8. Inspect the barrel for dents, score lines, or grooves

inside.

1 Barrel 5 Piston Wear Ring 9 Back-up ring 13 Rod

2 Piston 6 Nut 10 Wear Ring (2) 14 Grease Fitting

3 O-ring 7 Gland 11 Rod Seal

4Piston Seal 8 O-ring 12 Rod Wiper

Use appropriate eye protection when using

compressed air for cleaning or drying purposes.

Compressed air can cause serious personal

injury. Use safety reduction valves to reduce the

air pressure to a safe level before use.

It is important that all components are absolutely

clean, as contamination can result in serious

damage and/or improper operation.

Never use shop towels or rags to dry parts after

cleaning, as lint may clog passages. Dry parts

using compressed air.

Loading...

Loading...