8-32 673831-Rev A

CUTTING UNITS

8

Installation Notes

• Inspect bearing cone (9) for wear or damage.

Replace as needed.

• Pack bearing cone (9) with grease that meets or

exceeds NLGI Grade 2 LB specifications before

assembly.

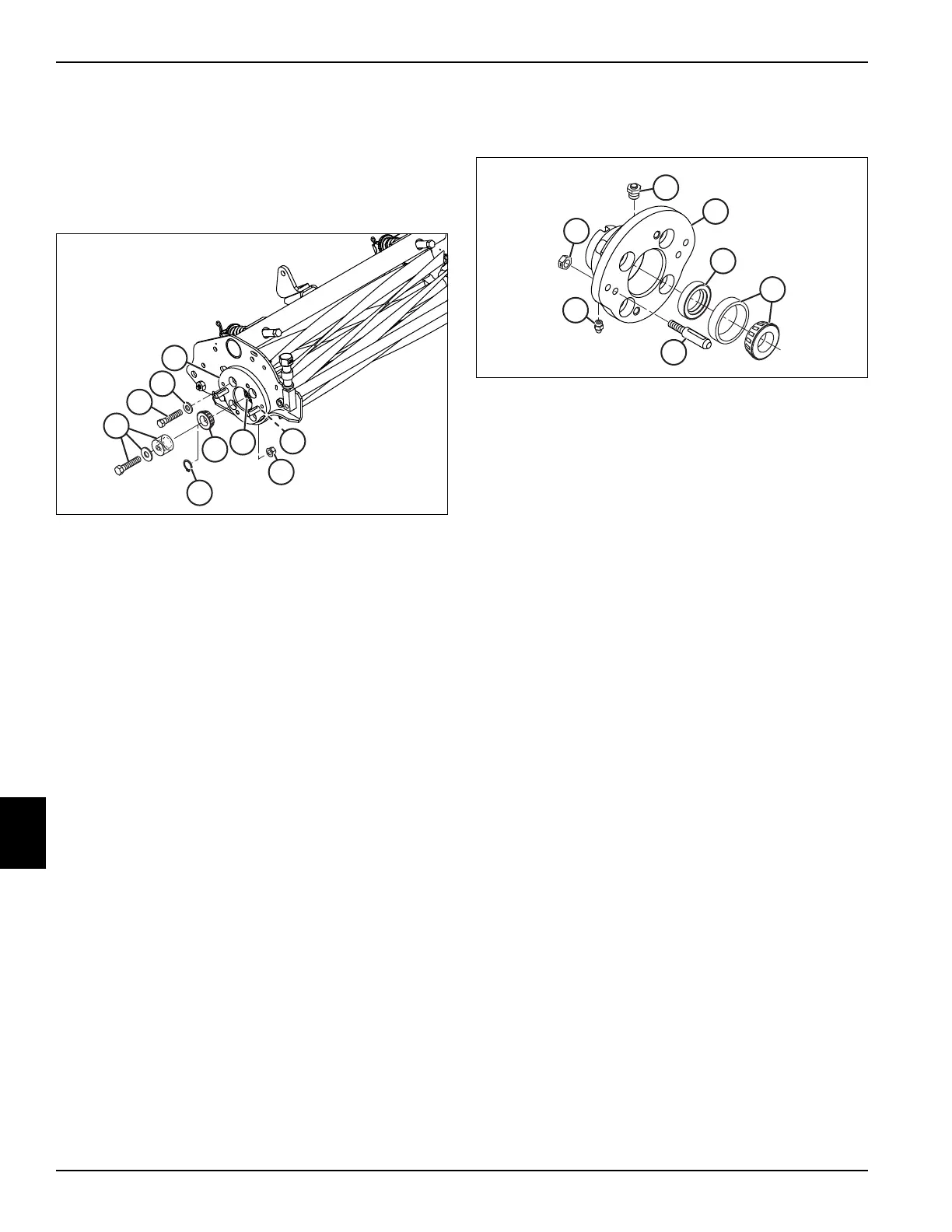

Figure 8-26

1. Loosely assemble bearing housing (6) to reel using

four screws (2), flat washers (3) and flange nuts (4).

2. Slide bearing cone (9) as far as possible onto reel

shaft.

3. Assemble bearing assembly tool (10) (Jacobsen PN

JAC5084) to end of reel shaft (7). Tighten tool until

bearing is fully seated on the reel shaft. Remove the

tool.

4. Assemble snap ring (1).

5. Tighten mounting screws (2) to 18–22 lb-ft (24.4–

29.8 N·m).

• Lubricate grease fitting (8) with grease that meets or

exceeds NLGI Grade 2 LB specifications. Clean

grease fitting before lubricating and apply grease to

the fitting with a hand grease gun only. Pump the gun

slowly until a slight amount of pressure is felt, then

stop—do not overgrease. Do not use an

air-powered grease gun.

• Adjust bedknife-to-reel clearance prior to installing

cutting unit to the mower. (See “Bedknife-to-Reel

Clearance Adjustment” on page 8-18.)

Disassembly and Assembly

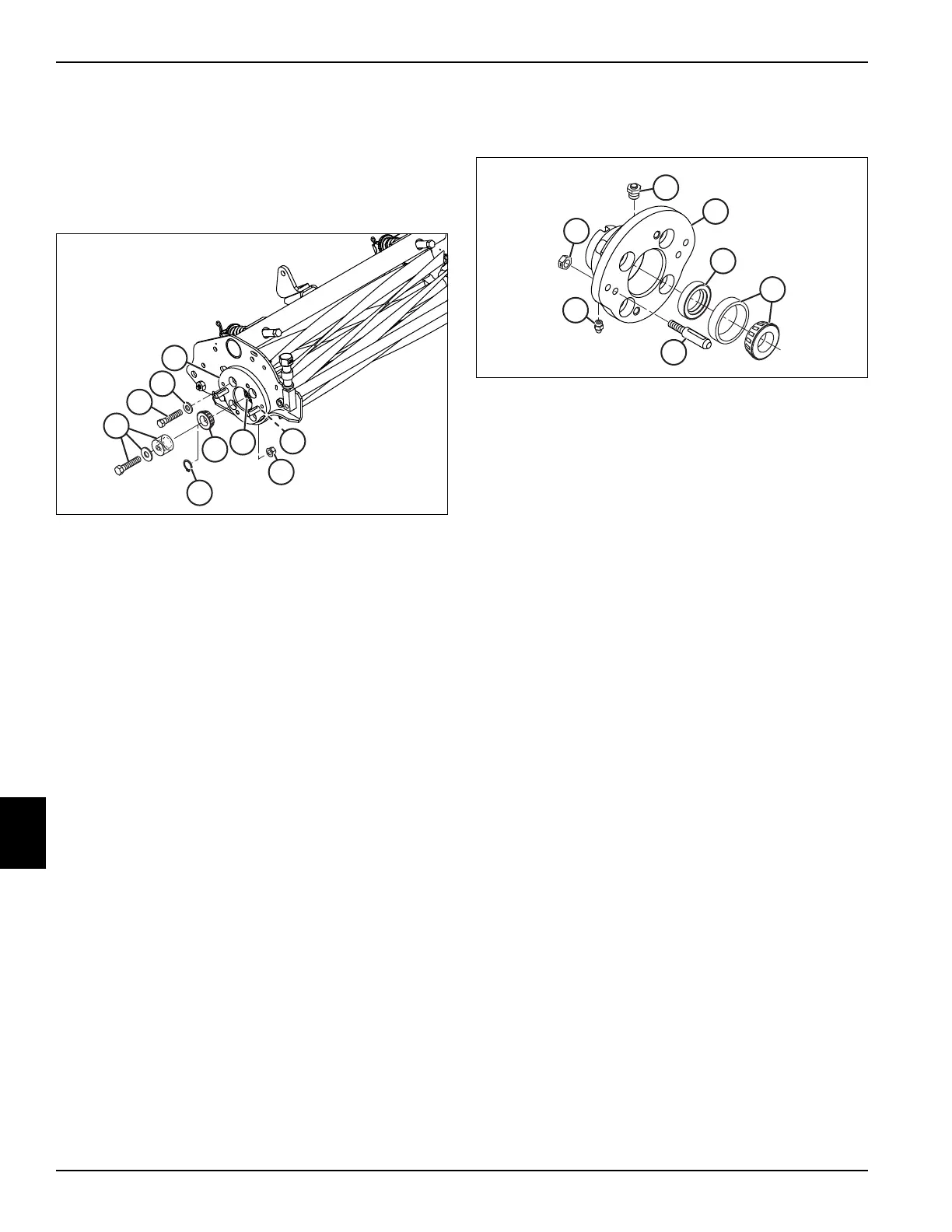

See Figure 8-27.

Figure 8-27

Assembly Notes

• Install new grease seal (2).

• Inspect bearing cup and cone (1) for wear or

damage. Replace as needed.

• Pack bearing (1) with grease that meets or exceeds

NLGI Grade 2 LB specifications before assembly.

• Apply grease that meets or exceeds NLGI Grade 2

LB specifications to the lips of grease seal (2).

1 Bearing Cup and Cone 5 Grease Fitting

2 Grease Seal 6 Motor Mounting Pin

3 Vent Fitting 7 Center Lock Nut

4 Reel Bearing Housing

Loading...

Loading...