3-13

3

4st 2/2.5/3.5 2007

12) Inspection of Compression Pressure

1. Start and idle engine for 5 minutes to warm up, and then stop.

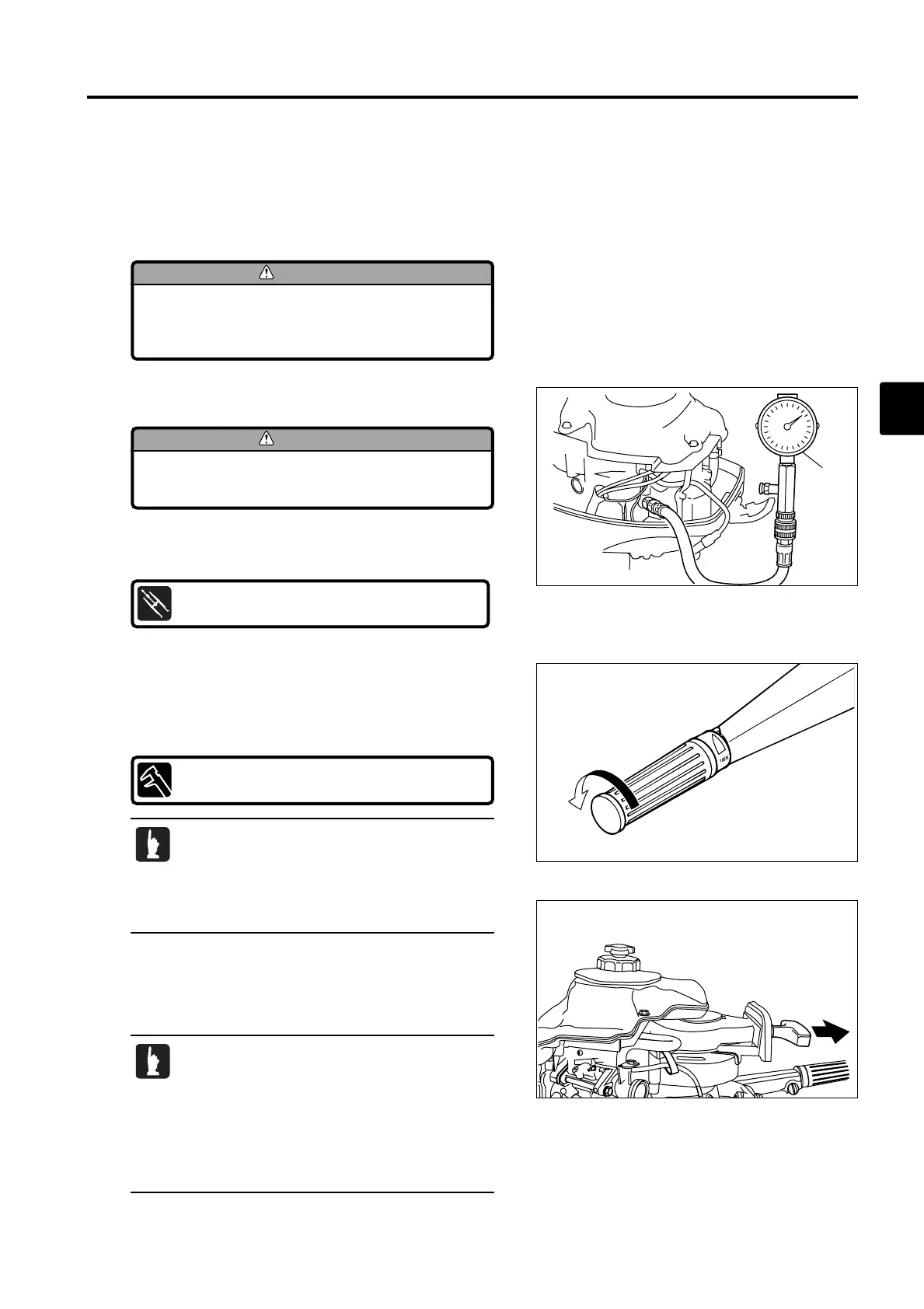

2. Shift gear into neutral (N).

3. Remove lock plate (of stop switch lanyard) from stop switch.

6. Fully open throttle a, crank engine until compression gauge

indication 1 stabilizes, and then measure compression

pressure.

7. If compression pressure is below specified value, put small

amount of engine oil into cylinder, and perform the test again.

Clean areas around spark plug on the

cylinder before removing spark plugs to

prevent dirt from entering cylinder.

Compression Gauge :

P/N. 3AC-99030-0

Compression Pressure (Reference) :

1.13 MPa (164 psi) [11.5 kgf/cm

2

]

• If compression pressure increases after the

above measure, check pistons and piston rings

for wear. Replace if necessary.

• If compression pressure does not increase

after the above measure, check valve

clearances, valves, valve seats and cylinder

sleeve. Adjust or replace if necessary.

To prevent accidental start of the engine,

remove lock plate (of stop switch lanyard)

from stop switch before measuring

compression pressure.

4. Remove plug cap and then spark plug.

5. Install compression gauge 1 to plug hole.

• Compression pressure is affected much by

cranking speed, and normally changes

approximately 10%.

• Do not pull choke knob when measuring

compression pressure.

MFS2sec03070524.qxd07.5.243:16 PM ページ13

Loading...

Loading...