5

5-27

4st 2/2.5/3.5 2007

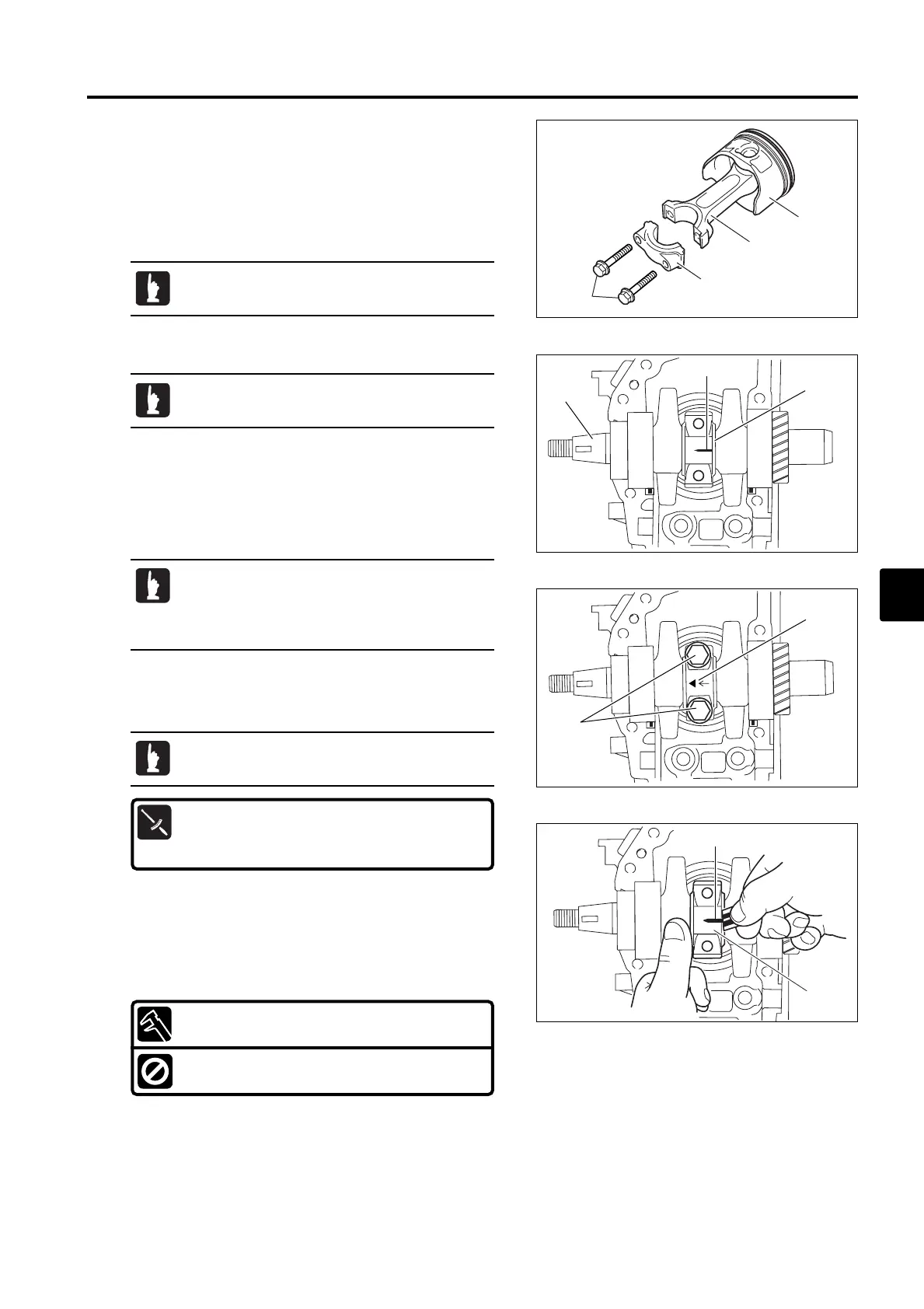

Connecting Rod Bolts :

1st

tightening torque : 5 N · m (4 lb · ft) [0.5 kgf · m]

2nd tightening torque : 10 N · m (7 lb · ft) [1.0 kgf · m]

6. Tighten connecting rod bolts 7 in two steps to specified

torque.

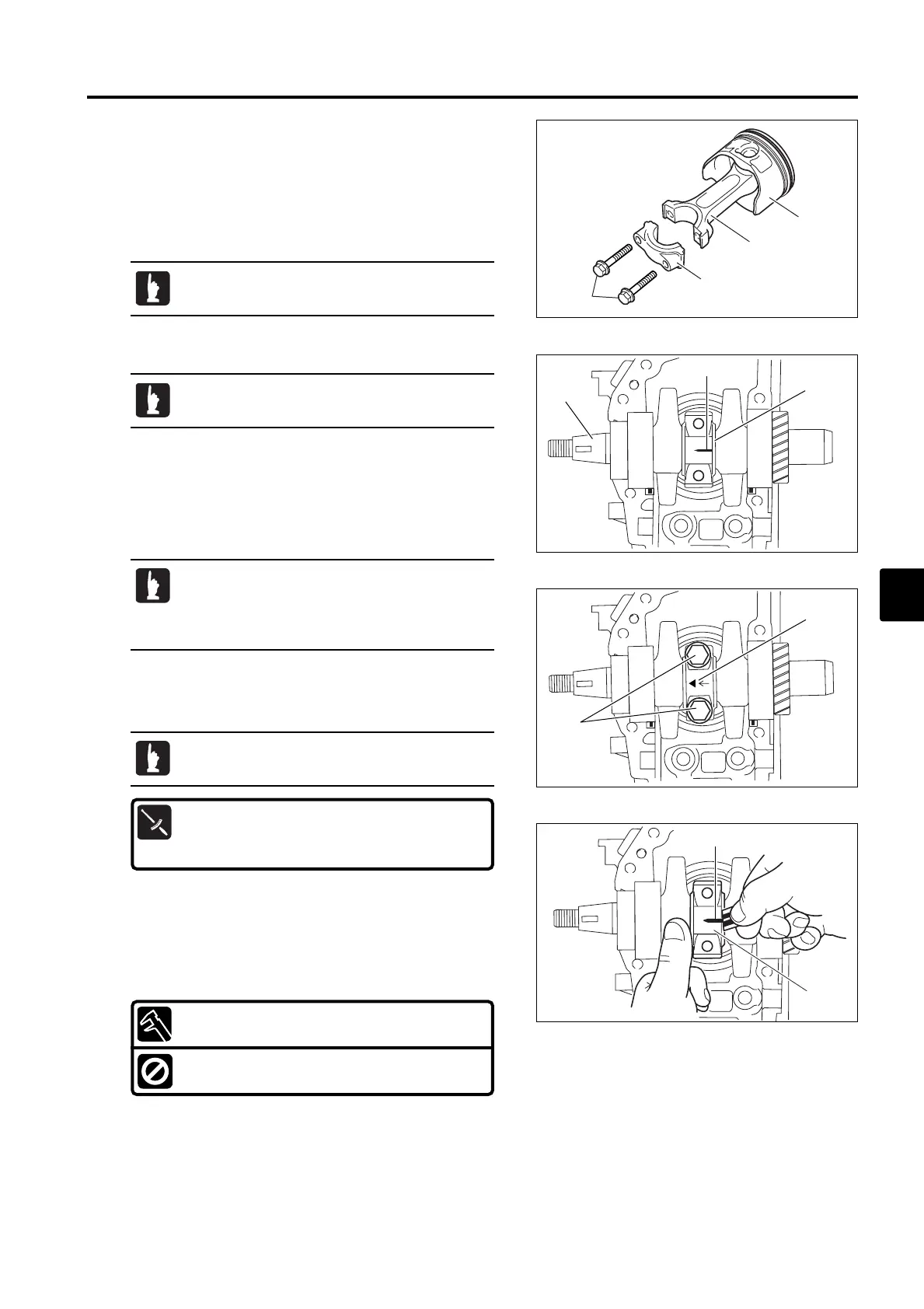

28) Inspection of Crank Pin Oil Clearance

1. Clean crank shaft 1 and connecting rod parts 2 and 3.

2. Place cylinder block upside down on the work bench.

Install piston 4 to connecting rod 2, and then, install the

assembly to cylinder block.

3. Install crank shaft 1 to cylinder block.

4. Place a commercially available plasti-gauge 5 on the

crank pin 6 so that is parallel to crank shaft 1.

5. Install connecting rod 2 and cap 3 to crank pin 6.

1

5

6

Do not move connecting rod and crankshaft until

oil clearance measurement is completed.

· Be sure to install the cap 3 in original position

(direction).

· Be sure that connecting rod "▲ " mark a

points crank shaft flywheel side.

7. Remove connecting rod cap 3 and measure width of

crushed plasti-gauge 5 on the crank pin 6. Replace

connecting rod 2 or crank shaft 1 if the measurement

(converted value) is over the limit.

Big End Oil Clearance : Converted value

0.015 - 0.041 mm (0.00059 - 0.00161 in)

Functional Limit :

0.060 mm (0.00236 in)

Do not attach piston rings in this step.

When installing, bring projection of bearing to notch

of cylinder block.

MFS2sec05070524.qxd07.5.243:18 PM ページ27

Loading...

Loading...