BRAKES,

WHEELS

AND

TIRES

f

Ie

is

advisable to lightly

grease

the

wheel

spindle

when replacing,

so

as

to facilitate future withdrawals

of

this Item.

Refer

to

Section

F17

regarding

wheel

replacement.

The chainwheel and

the

brake

disc

are

retained

by

four long studs which pass

through

the

hub.

The

hub itself consists

of

two

halves

which

are

pressed

together

during

production.

It

Is

not

advisable

to separate

the

two

half

hubs,

otherwise

difficulty

may be

experienced

with

spoke

tensioning

'"etc.

The chainwheel

or

the

brake

disc can be

removed

without

Interfering with

the

hub

assembly itself.

SECTION

FI9

FRONT

AND

REAR

WHEEL

ALIGNMENT

When

the

rear

wheel has been fitted

Into

the

swinging arm, It must be aligned

correctly

with

the

front wheel, for

otherwise

misalignment

will cause

steering

to

be affected adversly and

both

tires

and

chains to wear

excessively.

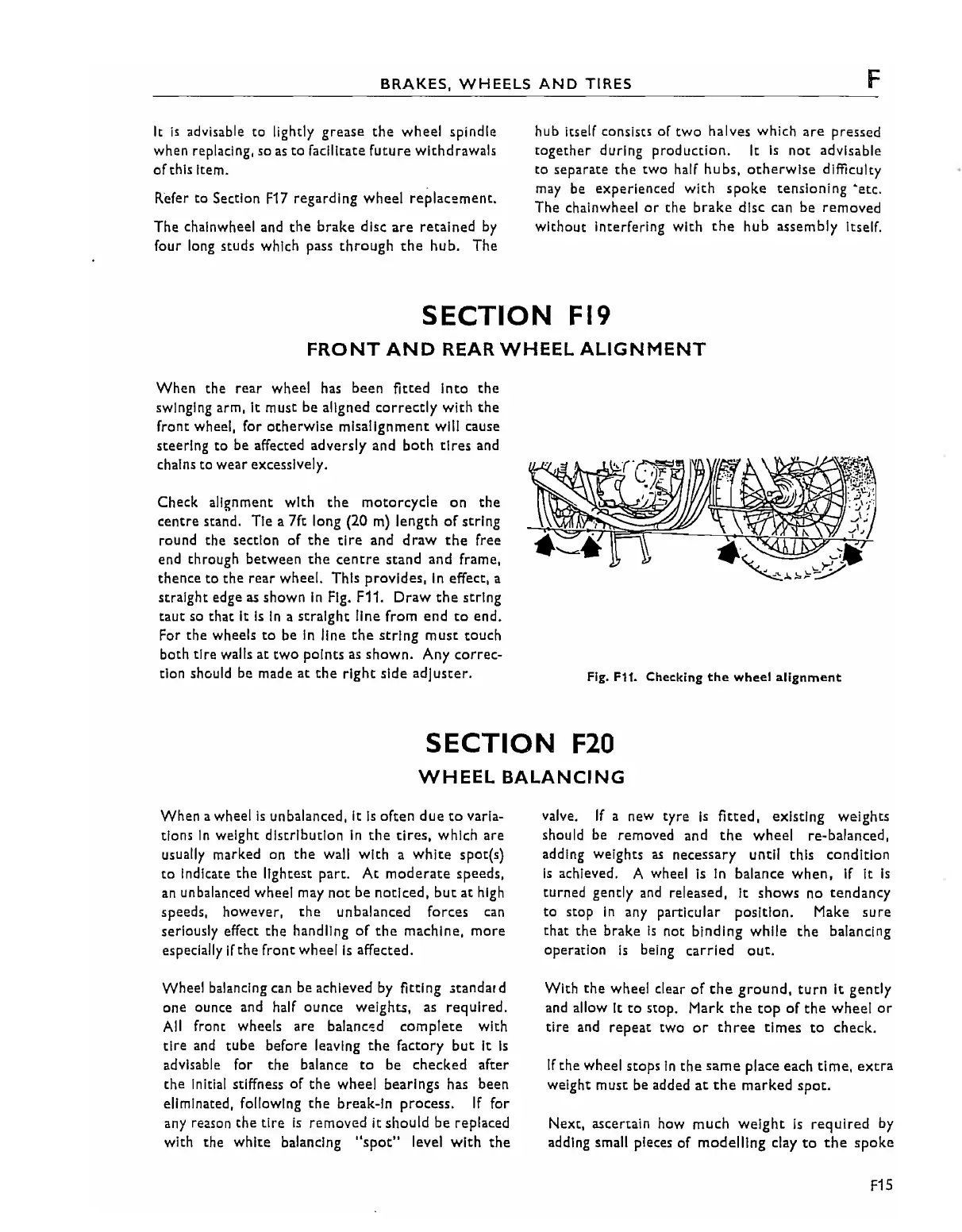

Check alignment with

the

motorcycle

on

the

centre

stand. Tie a 7ft long (20

m)

length

of

string

round the section

of

the

tire

and

draw

the

free

end through between

the

centre

stand and frame,

thence

to

the

rear

wheel. This prOVides,

In

effect, a

straight edge

as

shown

In

Fig. F11.

Draw

the

string

taut

so

that

It

Is

in

a

straight

line from

end

to

end.

For the wheels

to

be in line

the

string

muse touch

both

tire

walls

at

two

points as

shown.

Any

correc-

tion should be made

at

the

right

side

adjuster.

Fig.

F11.

Checking

the

wheel

alignment

SECTION

F20

WHEEL

BALANCING

When awheel

is

unbalanced,

It

Is

often due

to

varia-

tions

In

weight distribution

In

the

tires,

which are

usually marked on

the

wall

with

a

white

spotts)

to

Indicate

the

lightest part.

At

moderate

speeds,

an

unbalanced wheel may

not

be

noticed,

but

at

high

speeds,

however,

the

unbalanced

forces

can

seriously effect

the

handling

of

the

machine,

more

especially

If

the

front

wheelis

affected.

Wheel balancing can be achieved by fitting

.tandard

one

ounce

and

half ounce weights,

as

reqUired.

All

front wheels are balancod

complete

with

tire

and

tube

before leaving

the

factory

but

It

Is

advisable for

the

balance

to

be

checked

after

the

initial stiffness

of

the

wheel bearings has been

eliminated,

follOWing

the

break-in process.

If

for

any

reason

the

tire

is

removed

it

should be replaced

with

the

white

balancing

"spot"

level

with

the

valve.

If

a new tyre

Is

fitted,

eXisting weights

should be removed and

the

wheel

re-balanced,

adding weights

as

necessary until this condition

Is

achieved. A wheel

Is

in balance

when,

If

It

Is

turned gently and released,

it

shows

no

tendancy

to

stop

In

any particular pOSition. Make

sure

that

the

brake

Is

not

binding

while

the

balancing

operation

Is

being carried

out.

With

the

wheel clear

of

the

ground,

turn

It

gently

and allow It

to

stop. Mark

the

top

of

the

wheel

or

tire

and

repeat two

or

three

times

to

check.

If

the

wheel stops

In

the

same

place each

time,

extra

weight must be added

at

the

marked

spot.

Next, ascertain how much weight

is

reqUired

by

adding small pieces

of

modelling

clay

to

the

spoke

F15

Loading...

Loading...