G

TELESCOPIC

FORKS

Take

off

the

nuts

under the

top

yoke, whIch

secure

the

handlebar brackets, then

11ft

off

the

handlebars

and

lay

them

on

the

tank, using a thick

piece

of

cloth

or

something

similar

to

prevent

scratching

Remove

the

two

forward facing bolts whlLh

secure

the

binnacle assembly

to

the

top

yoke, and discon-

nect

the

drives

to

the tachometer

and

speedometer.

Slacken

the

screW on

top

of

the

head lamp shell and

prise

off

-the

rim.

Disconnect

the

green leads

from

the

front

flasher lamps, and remove

the

lamps and

stalks (See Section H14). Remove

the

headlamp

and Its

mounting,

and

lay

It aside,

together

with

the

binnacle assembly.

Disconnect

the

front

brake pipe unions and

remove

the

pipes.

If

it

Is

necessary

to

remove

the

brake

caliper, see Section

F13.

Remove

the

dust

cover from

the

top

of

each

fork

stanchion

by unscrewing

In

an

anti-clockWise

dlrec-

tlon.

Unscrew

the

two

socket type clamp bolts,

located

at

the

rear

of

the

top

fork yoke, and

then

unscrew

the

alun-Inium cap

screw

from

the

top

of

each stanchion using a suitable sized

socket

wrench.

Remove

the

Internal fork springs. Using Service

Tool

61-6113

placed down Into

the

stanchion, hold

the

valve assembly while

the

retaining

socket

screw

In

the

base

of

the

fork leg

Is

being

unscrewed.

The

tip

of

Service Tool

61-6113

Is

rounded.

For

more

recent

forks,

it

will

be

advantageous

to

grind

a flat

on

the

tip, making it

screwdriver

shaped.

At

this stage,

it

will be possible

to

remove

the

fork

leg by sliding It from

the

stanchion. Slacken

the

pinch bolts

on

the

bottom yoke

In

order

to

with-

draw

the

stanchion.

When

refitting,

tighten

the

pinch bolts

to

2S

Ibs/ft.

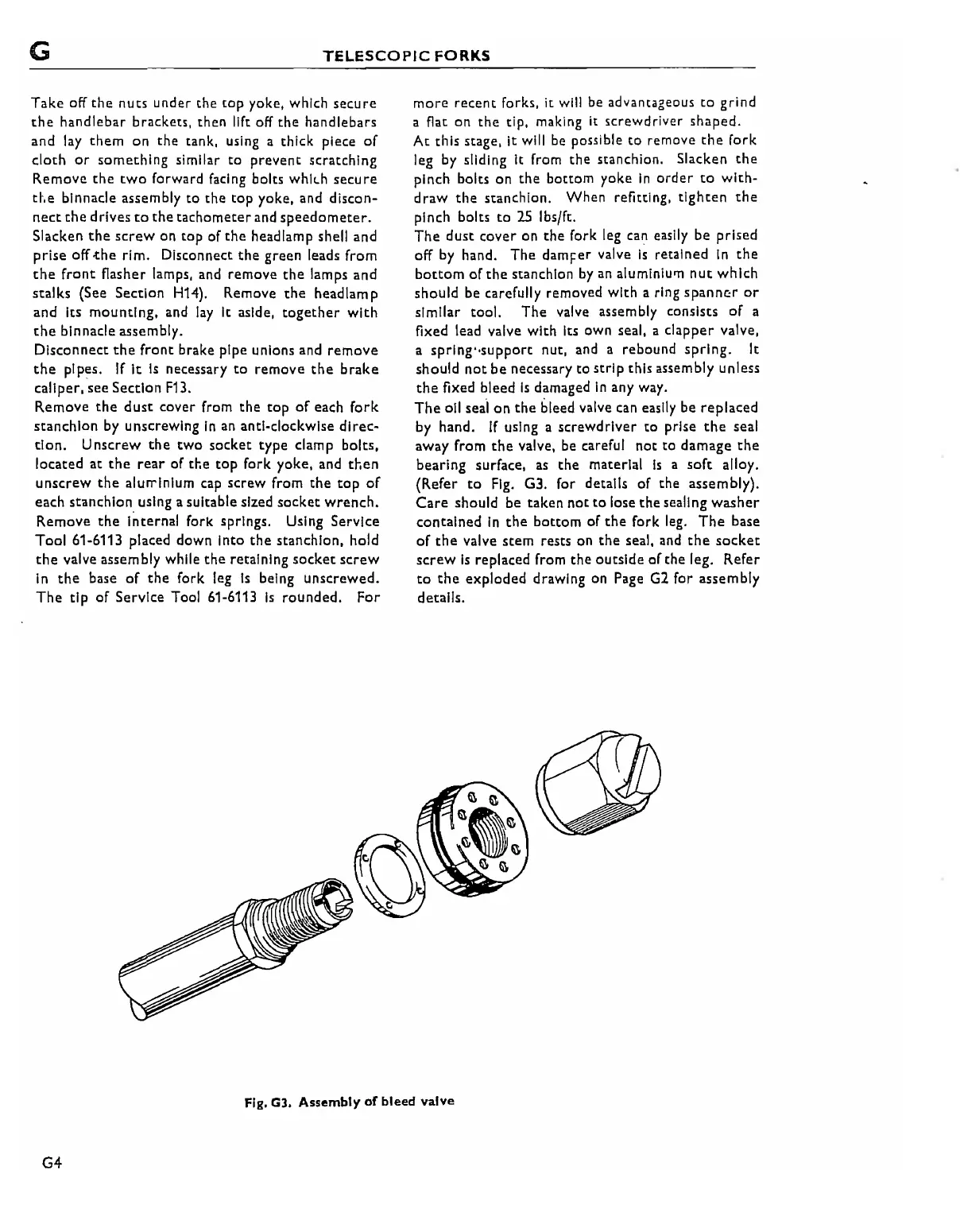

The

dust

cover

on

the

fork leg can easily be prlsed

off by hand.

The

damFer valve

Is

retained

In

the

bottom

of

the

stanchion

by

an

alumlnlu",

nut

which

should be carefully removed with a ring

spanner

or

similar tool.

The

valve assembly consists

of

a

fixed lead valve with its own seal, a clapper valve,

a

sprlng"support

nut, and a rebound

spring.

It

should

not

be

necessary to

strip

this assembly unless

the

fixed bleed

Is

damaged

In

any way.

The

011

seal

on

the

bleed valve can easily be

replaced

by hand.

If

using a

screwdriver

to

prise

the

seal

away from

the

valve, be careful

not

to damage

the

bearing surface,

as

the material

Is

a

soft

alloy.

(Refer

to

Fig.

G3. for details

of

the assembly).

Care

should be taken

not

to

lose

the

sealing

washer

contained

In

the

bottom

of

the

fork leg.

The

base

of

the

valve

stem

rests on

the

seal,

and

the

socket

screw

Is

replaced from

the

outside

of

the leg. Refer

to

the

exploded drawing on Page

G2

for assembly

details.

Fig. G3. Assembly

of

bleed valve

G4

Loading...

Loading...