c

PRIMARY

DRIVE

Straighten

the

tabs

of

the

locking plates and remove

the

six

bolts

retaining

the

outer

plate. After

the

screws

are removed.

the

plate can be lifted off

and

the

rubber

segments exposed. At this stage,

the

hexagon

portion

of

the

leverage bar

'should

be

placed

In

the

splines

of

the

shock

absorber

spider.

A

strong

pull on

the

bar will then

rotate

the

spider,

and

compress

one

set

of rubbers. The bar will be

held

In

this portion

by

Inserting a

screwdriver

blade

or

a

tommy

bar

through

the

hole

In

the

bar

to

engage

with

the

sprocket

teeth.

The

first

set

of

rubbbers

can then be lifted oUt. Carefully restrain

the

bar

whilst

the

screwdriver blade

Is

withdrawn.

At

this

stage

the

remaining sets

of

rubbers

will be

free

for

removal, and

the

spider can be lifted oUt.

One

type

of

rubber

is

used for both drive and

rebound.

Fit

the

new rubbers Into place, using

the

mounting

Jig

and bar. Then fit

the

retaining

plate. followed

by

the

locking plates and

the

bolts. securing these with

the

tabs

of

the

locking

plates.

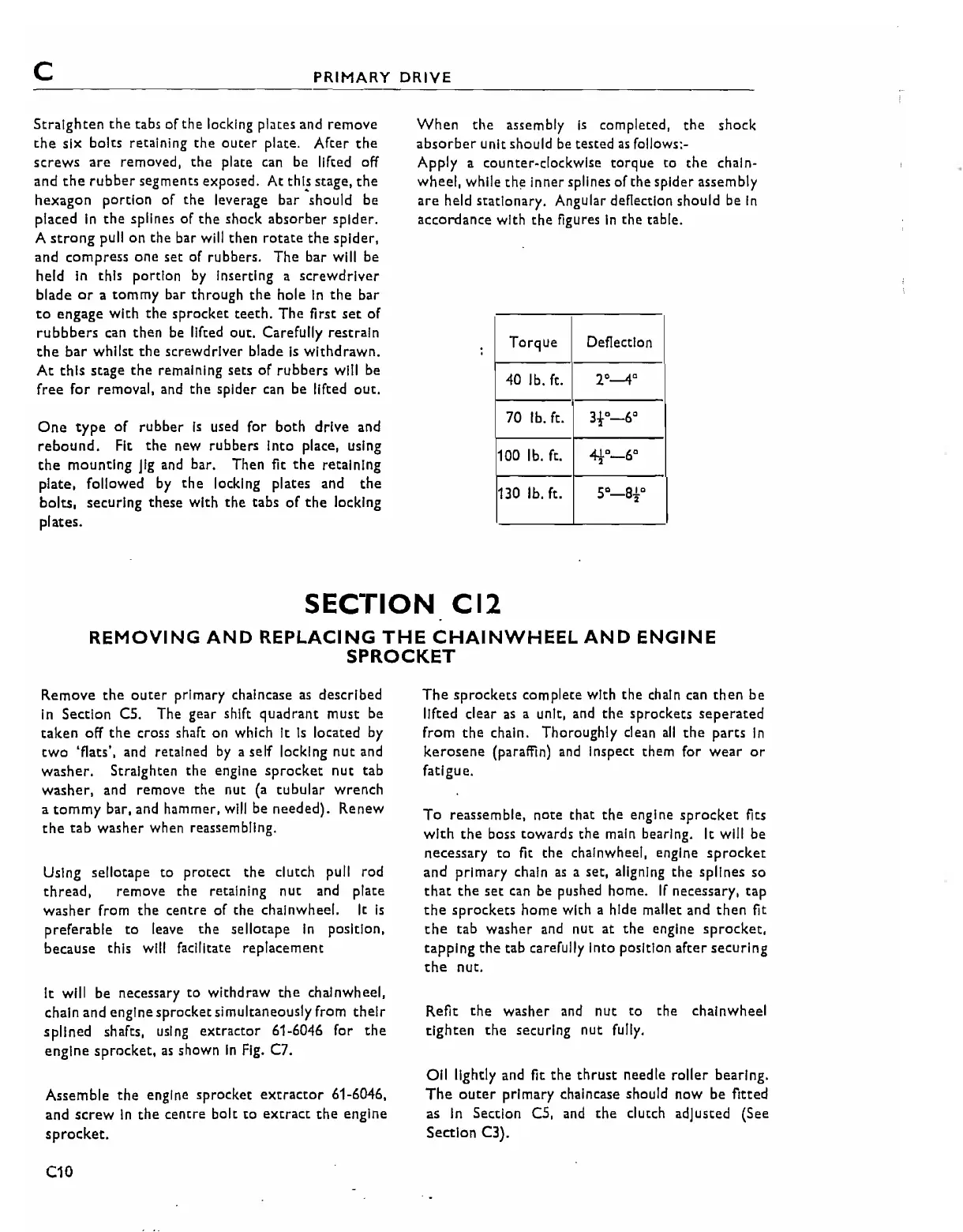

When

the

assembly

is

completed,

the

shock

absorber

unit should be tested

as

follows:-

Apply a counter-clockwise

torque

to

the

chain-

wheel, while

the

Inner splines

of

the spider assembly

are

held stationary. Angular defiection should be

In

accordance with

the

figures

In

the

table.

Torque

Defiectlon

40 lb. ft.

2°-4

0

70 lb. ft.

3to-6°

100 lb. ft.

4t

D

_

6

°

130 lb. ft.

5°_

B

t

C

SECTION

CI2

REMOVING

AND

REPLACING

THE

CHAINWHEEL

AND

ENGINE

SPROCKET

Remove

the

outer

primary chaincase

as

described

In

Section

CS.

The gear shift

quadrant

must be

taken

off

the

cross shaft on which It

Is

lotated

by

two

'flats', and retained

by

a self locking

nut

and

washer.

Straighten

the

engine

sprocket

nut

tab

washer,

and

remove

the

nut

(a

tubular

wrench

a

tommy

bar, and hammer.

will

be needed). Renew

the

tab

washer when reassembling.

Using sellotape

to

protect

the

clutch pull rod

thread, remove the retaining

nUt

and

plate

washer

from

the

centre

of

the chainwheel. It

is

preferable

to

leave

the

sellotape

in

position.

because this will facilitate replacement

It will be necessary

to

withdraw

the

chainwheel,

chain and engine sprocket simultaneously from

their

splined shafts, using

extractor

61-6046 for

the

engine

sprocket,

as

shown

In

Fig.

C7.

Assemble

the

engine sprocket

extractor

61-6046,

and

screw

In

the

centre bolt

to

extract

the

engine

sprocket.

C10

The

sprockets

complete with

the

chain can

then

be

lifted clear

as

a unit, and

the

sprockets

seperated

from

the

chain. Thoroughly clean

all

the

parts

In

kerosene

(paraffin) and Inspect them for

wear

or

fatigue.

To

reassemble, note that

the

engine

sprocket

fits

with

the

boss towards

the

main bearing. It will be

necessary

to

fit the chainwheel, engine

sprocket

and primary chain

as

a set, aligning

the

splines so

that

the

set

can be pushed home.

If

necessary,

tap

the

sprockets

home with a hide mallet and

then

fit

the

tab

washer and nut at

the

engine

sprocket,

tapping

the

tab carefully into position

after

securing

the

nut.

Refit

the

washer and

nut

to

the

chainwheel

tighten

the

securing

nut

fully.

Oil lightly and fit

the

thrust

needle

roller

bearing.

The

outer

primary chaincase should now be fitted

as

In

Section C5, and

the

clutch adjusted (See

Seetlon C3).

Loading...

Loading...