ENGINE

B

ALTITUDE

The settings given on page

GD4

are

those

normally

recommende':; and will

be

suitable

for most

atmospheric conditions.

They

are

Intended for

altitudes up

to

3,OOOft.

(1000m).

Above

this height

some reduction

in

main Jet size is necessary

to

provide a balanced

mixture.

For

altitudes

between

3,000 ft. and 6,000 ft. (2,000 m.) a

reduction

In

main

Jet size by 5

per

cent

Is

usually necessary, and for

every 3,000 ft. Increase

over

6,000 ft. a

furtherA

per

cent

Is

required.

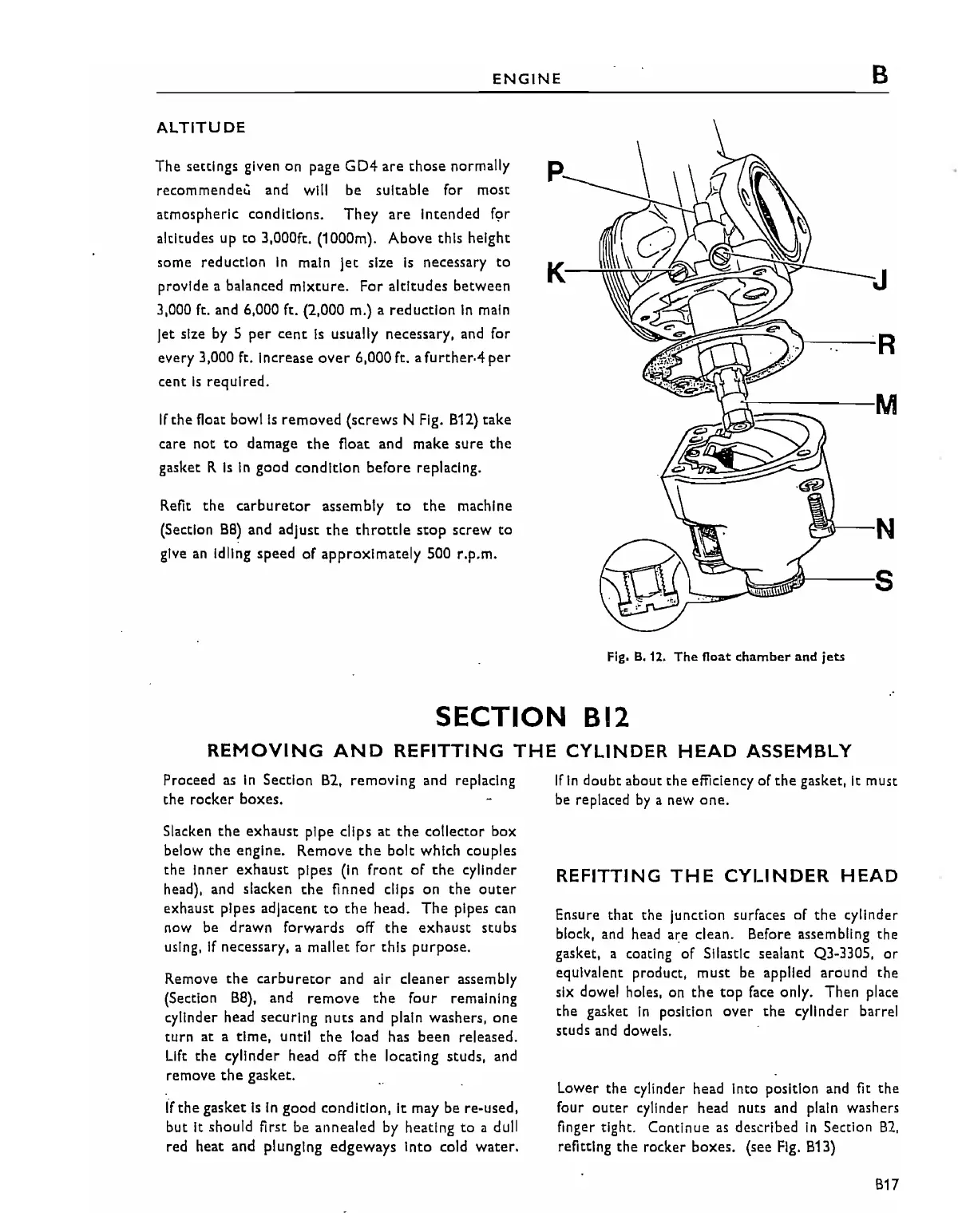

If

the

float bowl

Is

removed

(screws

N Fig.

B12)

take

care not

to

damage

the

float

and

make sure the

gasket R

Is

In

good

condition

before

replacing.

Refit

the

carburetor

assembly

to

the

machine

(Section

BB)

and

adjust

the

throttle

stop

screw

to

give

an

Idling speed

of

approximately

500 r.p.m.

p

K

J

IIl---N

Fig.

B.

12.

The float chamber and

jets

SECTION

812

REMOVING

AND

REFITTING

THE

CYLINDER

HEAD

ASSEMBLY

Proceed

as

In

Section

B2,

removing

and replacing

the

rocker

boxes.

Slacken

the

exhaust

pipe clips

at

the

collector

box

below

the

engine. Remove

the

bolt

which couples

the

Inner

exhaust

pipes (In

front

of

the

cylinder

head), and slacken

the

finned clips on

the

outer

exhaust pipes adjacent

to

the

head.

The

pipes can

now be

drawn

forwards

off

the

exhaust

stubs

using,

If

necessary, a mallet for this purpose.

R.emove

the carburetor

and

air cleaner

assembly

(Section

BB),

and

remove

the

four

remaining

cylinder head

securing

nuts

and plain washers,

one

turn

at a

time,

until

the

load has been released.

Lift

the

cylinder head off

the

locating studs, and

remove

the

gasket.

if

the

gasket

Is

In

good

condition,

It may

be

re-used,

but It should first

be

annealed by heating

to

a dull

red heat and plunging

edgeways

Into cold

water.

If

In

doubt about

the

efficiency

of

the

gasket, It must

be replaced

by

a new

one.

REFITTING

THE

CYLINDER

HEAD

Ensure that

the

Junction surfaces

of

the

cylinder

block, and head are clean. Before assembling the

gasket, a coating

of

Sllastlc sealant Q3-330S,

or

equivalent product,

must

be applied

around

the

six dowel holes, on

the

top

face only.

Then

place

the

gasket

In

position

over

the

cylinder

barrel·

studs and dowels.

Lower

the

cylinder head Into position and fit

the

four

outer

cylinder head nuts and plain washers

finger tight. Continue

as

described

In

Section

B2,

refitting

the

rocker boxes. (see

Fig.

B13)

B17

Loading...

Loading...