ENGINE

B

It

Is

advisable

at

this

sugeto

remove

the

oil

pressure release valve (Section A6).

The

tacho-

meter

drive can

now

be

removed

from

the

crankcase

(Section 836).

Remove four self locking nUts and

washers

from

the

main bearing caps, and

as

the

caps

are

located on

waisted studs.

the

crank

should

be

lifted

to

free

them.

Under

no

circumstances

should

the

caps

be

prised

off. After removing

the

crankshaft

the

connecting rods and big end shells can be removed.

The caps are retained by self locking

nuts,

and

after

removal of

the

connecting rods

the

caps should be

refitted

to

them

to

ensure

that

they

are

reasembled

to

the

corresponding connecting

rods.

The gearbox

sprocket

and high

gear

should be

removed (Sections D7, D11)

In

order

to

check

the

condition of

the

high

gear

bearing

and

oil seal.

If

these parts

are

worn

they

should

be

replaced. Do

not

attempt

to

use a seal which has

shown

signs of

leakage. Remove six

nuts

and plain washers

securing the sump plate

to

the

centre

crankcase

section. and then

the

plate.

two

gaskets

and

the

metal gauze filter. This filter

should

be

cleaned

thoroughly

In

gasolene (petrol). It

Is

advisable.

at

this stage.

to

remove

the

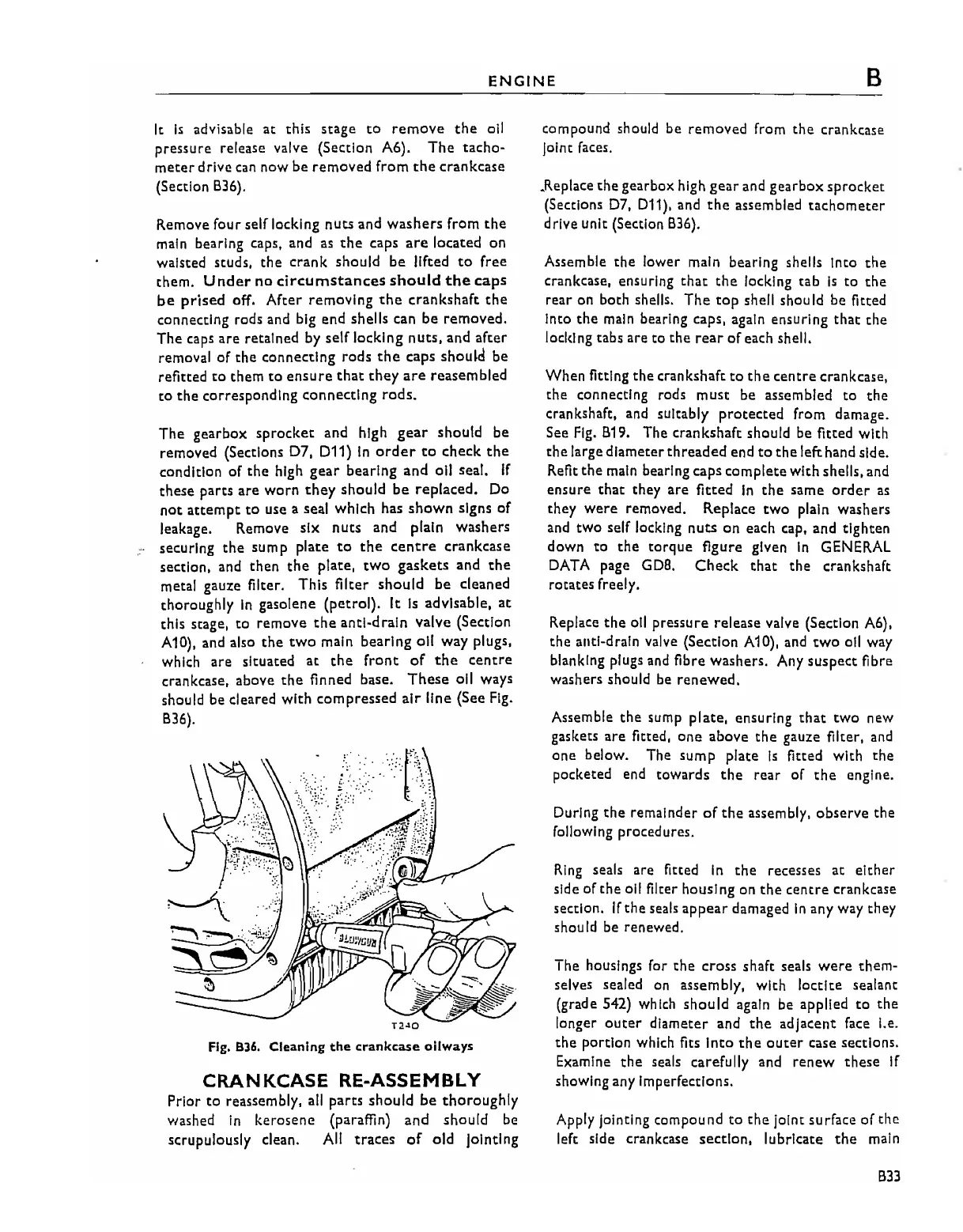

anti-drain valve (Section

A10), and also

the

two

main bearing oil way plugs,

which are situated

at

the

front

of

the

centre

crankcase. above

the

finned base.

These

oil ways

should be cleared with compressed

air

line (See

Fig.

836).

Fig. 836.

Cleaning

the

crankcase

oilways

CRANKCASE RE-ASSEMBLY

Prior

to

reassembly,

all

parts should

be

thoroughly

washed

in

kerosene (paraffin)

and

should

be

scrupulously

dean.

All

traces

of

old Jointing

compound should be removed from

the

cranktase

joint faces.

.Replace

the

gearbox high

gear

and gearbox

sprocket

(Sections

D7,

011). and

the

assembled

tachometer

drive unit (Section 836).

Assemble

the

lower main bearing shells Into

the

crankcase. ensuring

that

the

locking tab

Is

to

the

rear on both shells.

The

top

shell shou

Id

be fitted

Into the

main

bearing caps,

again

ensuring that the

locking tabs are to

the

rear

of

each shell.

When fitting the crankshaft

to

the

centre

crankcase,

the connecting rods must be assembled to

the

crankshaft, and sUitably

protected

from damage.

See

Fig.

819. The crankshaft should be fitted with

the

large diameter

threaded

end

to

the

left hand side.

Refit

the

main bearing caps complete with shells. and

ensure

that

they are fitted

In

the

same

order

as

they

were

removed. Replace

two

plain washers

and two self locking

nuts

on

each cap, and tighten

down

to

the

torque

figure given

In

GENERAL

DATA

page

GDB.

Check

that

the

crankshaft

rotates freely.

Replace

the

oil pressure release valve (Section A6),

the anti-drain valve (Section A10). and

tWO

oil way

blanking plugs and fibre washers. Any suspect fibre

washers should

be

renewed.

Assemble the

sump

plate. ensuring that

two

new

gaskets are fitted,

one

above

the

gauze filter.

and

one below. The sump plate

Is

fitted with the

pocketed end towards

the

rear

of

the

engine.

During

the

remainder

of

the

assembly, observe the

following procedures.

Ring

seals are fitted

in

the

recesses at

either

side of the all filter housing on

the

centre

crankcase

section.

If

the

seals

appear

damaged

In

any way they

should be renewed.

The housings for

the

cross shaft seals

were

them-

selves sealed

on

assembly, with

loctlte

sealant

(grade S42) which

should

again be applied

to

the

longer

outer

diameter and

the

adjacent face I.e.

the

portion which fits Into

the

outer

case sections.

Examine

the

seals carefully and

renew

these

if

showing any Imperfections.

Apply jointing compound

to

the

joint surface of the

left side crankcase section, lubricate

the

main

833

Loading...

Loading...