c

PRIMARY

DRIVE

The dutch

hub

nut

then requires removal

With

a

tubular

wrench.

tommy

bar. and

hammer.

The

clutch hub

Is

keyed and

tapered

to the

transmission

malnshaft,

a~nd

can

only be removed

using

extractor

60-B60 which screws Into

the

end of

the

spllned

hub.

The

clutch cover

is

secured

by

three

screws

only.

after

removal

of

which, It

can

be lifted clear.

The

breather

duct

cover

and gasket

are

secured

to the

c1utch

..

cover

With

four screwa.

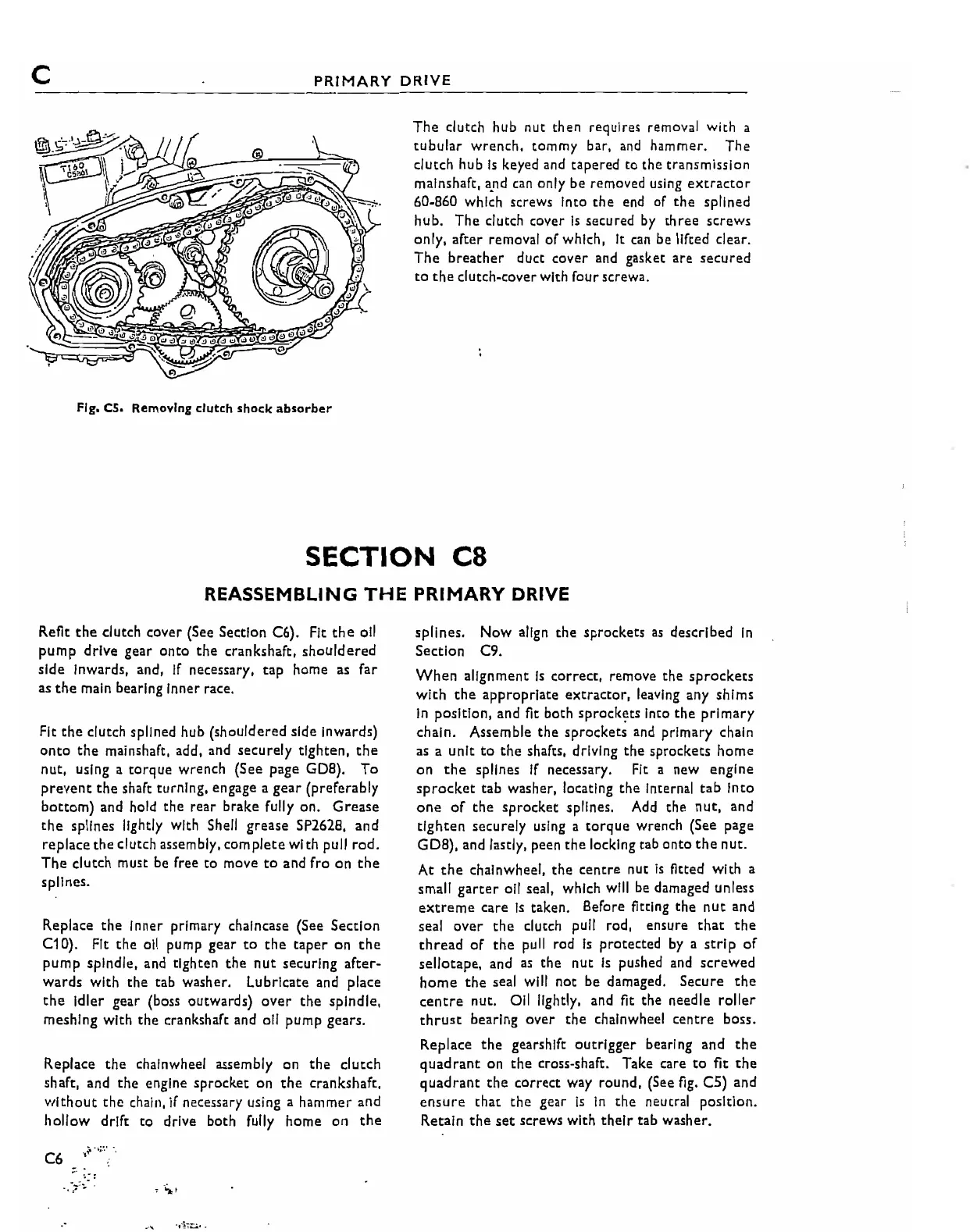

FIg.

CS.

Removing clutch shock absorber

SECTION

C8

REASSEMBLING

THE

PRIMARY

DRIVE

Refit

the

clutch

cover

(See Section C6). Fit

the

oil

pump

drive

gear

onto

the

crankshaft,

shouldered

side Inwards,

and,

if necessary, tap home

as

far

as

the

main bearing Inner race.

Fit

the

clutch spllned hub

(shouldered

side Inwards)

onto

the

mainshaft, add. and

securely

tighten,

the

nut.

using a

torque

wrench (See page GOB).

To

prevent

the

shaft turning, engage a

gear

(preferably

bottom)

and hold

the

rear

brake fully on.

Grease

the

splines lightly with Shell

grease

SP262B,

and

replace

the

clutch assembly,

complete

with

pull

rod.

The

clutch must be free

to

move

to

and fro

on

the

splines.

Replace

the

Inner primary chalncase (See

Section

C10). Fit

the

all pump

gear

to

the

taper

on

the

pump

spindle, and tighten

the

nut

securing

after-

wards

with

the

tab washer. Lubricate and place

the

Idler

gear

(boss outwards)

over

the

spindle,

meshing

with

the

crankshaft and oil

pump

gears.

Replace

the

chainwheel assembly on

the

clutch

shaft, and

the

engine

sprocket

on

the

crankshaft,

without the

chain,

if

necessary using a hammer

and

hollow

drift

to

drive both fully

home

on

the

splines.

Now

align

the

sprockets

as

described

In

Section

C9.

When

alignment

Is

correct, remove the sprockets

with

the

appropriate

extractor,

leaving any

shims

In

position,

and fit both

sprock~ts

Into

the

primary

chain. Assemble

the

sprockets

and

primary

chain

as

a

unit

to

the

shafts, driving

the

sprockets

home

on

the

splines

If

necessary. Fit a

neW

engine

sprocket

tab washer, locating

the

Internal

tab

Into

one

of

the

sprocket

splines. Add the

nut,

and

tighten

securely using a

torque

wrench (See page

GDB), and lastly, peen

the

locking tab

onto

the

nut.

At

the

chainwheel,

the

centre

nut

is

fitted

with

a

small

garter

oil seal, which will be damaged unless

extreme

care

Is

taken. Before fitting the nut

and

seal

over

the

clutch pull rod, ensure

that

the

thread

of

the

pull rod

Is

protected

by

a

strip

of

sellotape,

and

as

the

nut

Is

pushed and

screwed

home

the

seal will

not

be damaged.

Secure

the

centre

nut. Oil lightly, and fit the needle

roller

thrust

bearing

over

the

chainwheel

centre

boss.

Replace

the

gearshift

outrigger

bearing

and

the

quadrant

on

the

cross-shaft. Take care

to

fit

the

quadrant

the

correct

way

round,

(See fig.

C5)

and

ensure that the gear

is

in

the neutral position.

Retain

the

set

screws with

their

tab washer.

Loading...

Loading...