ENGINE

B

To grind

In

the valve

Use

a fine grade carborundum

grinding paste

but

before

returning

the

valve

to

Its

seat, insert a

light

spring

under

its head

to

assist

In

raising

the valve when

rotating

to

a

new

position

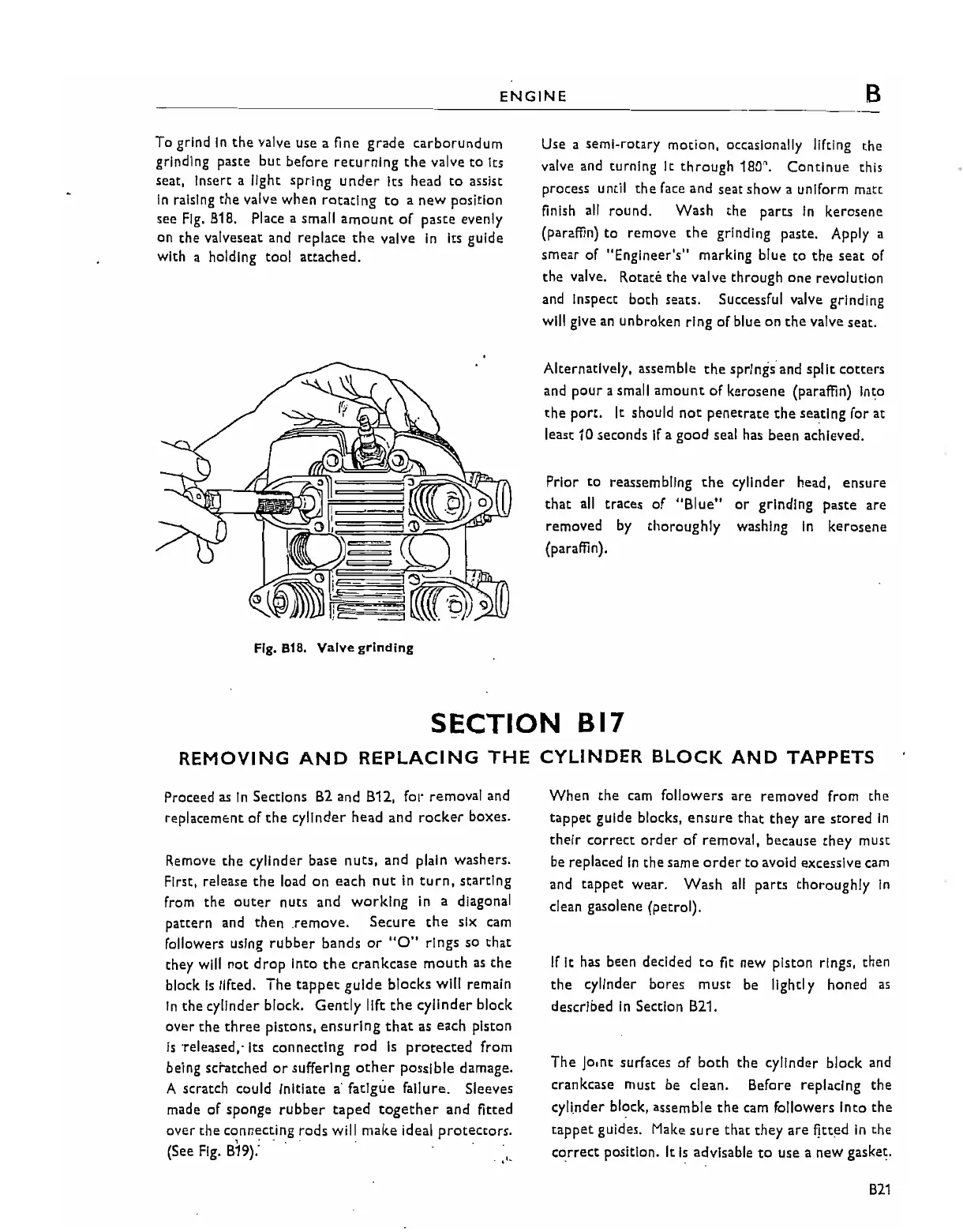

see Fig. 818. Place a small

amount

of

paste

evenly

on

the

valveseat and

replace

the

valve

In

Its gUide

with a holding tool

attached.

Fig. 818. Valve grinding

Use

a semi-rotary

motion,

occasionally lifting the

valve and

turning

It

through

180'.

Continue

this

process until

the

face and seat

show

a uniform matt

finish

all

round.

Wash

the

parts

In

kerosene

(paraffin)

to

remove

the

grinding paste. Apply a

smear

of

"Engineer's"

marking blue

to

the

seat

of

the

valve. Rotate

the

valve

through

one

revolution

and Inspect both seats. Successful valve grinding

will give an

unbroken

ring

of

blue on

the

valve seat.

Alternatively. assemble

the

springs and

spilt

cotters

and

pour

a small

amount

of

kerosene

(paraffin) Into

the

port.

It should

not

penetrate

the

seating for at

least

10 seconds

If

a

good

seal has

been

achieved.

Prior

to

reassembling

the

cylinder head,

ensure

that

all

traces

of

"Blue"

or

grinding

paste

are

removed by

thoroughly

washing

In

kerosene

(paraffin).

SECTION

BI7

REMOVING

AND

REPLACING

THE

CYLINDER

BLOCK

AND

TAPPETS

Proceed

as

In

Sections

B2

and B12,

fOI'

removal

and

replacement

of

the

cylinder

head

and

rocker

boxes.

Remove

the

cylinder base

nuts.

and plain washers.

First, release

the

load

on

each

nut

in

turn,

starting

from

the

outer

nUts

and

working

In

a diagonal

pattern

and

then .remove. Secure

the

six

cam

followers using

rubber

bands

or

"0"

rings

so

that

they will

not

drop

Into

the

crankcase

mouth

as

the

block

Is

lifted.

The

tappet

guide

blocks

will remain

In

the

cylinder block.

Gently

lift

the

cylinder

block

over

the

three

pistons,

ensuring

that

as each piston

is

·released," Its

connecting

rod

Is

protected

from

being

scratched

or

suffering

other

possible

damage.

A scratch could Initiate a'

fatigue

failure. Sleeves

made

of

sponge

rubber

taped

together

and

fitted

over the connecting rods will make ideal

protectors.

(See

Fig.

B19).'·'

,

When

the

cam followers

are

removed

from

the

tappet

guide blocks,

ensure

that

they

are

stored

In

their correct order

of

removal, because

they

mUst

be replaced

In

the same

order

to

avoid

excessIve

cam

and

tappet

wear.

Wash

all

parts

thoroughly

In

clean gasolene

(petrol).

If

It has been decided

to

fit new piston rings, then

the

cylinder bores

must

be light! y

honed

as

described

In

Section B21.

The

joont surfaces

of

both

the

cylinder

block

and

crankcase must be clean. Before replacing

the

cyllnder block, assemble

the

cam followers

Into

the

tappet

guides. Make su

re

that

they

are

fjtted

In

the

correct

position. It

Is

advisable

to

use a

new

gasket.

B21

Loading...

Loading...