LUBRICATION

SYSTEM

SECTION AIO

ANTI-DRAIN

VALVE

A

The

anti-drain valve

Is

situated

In

the

crankcase

centre

section adjacent

to

the

oil pump housing.

The purpose of

the

valve

Is

to

prevent

oil draining

through from

the

feed side of

the

pump

when

the

engine

Is

stationary

overnight,

or

when

the

pump

has

suffered a

great

deal of

wear.

If

this condition

Is

evident (Indicated

by

voluminous

smoke

from the

exhaust), It

must

be assumed

that

the

ball

of

this

valve

Is

sticking,

or

Is

being held off Its seating

by

some means.

To

clean

the

bail and spring, hold the

cupped hand beneath

the

valve,

remove

the

plug

from

the

crankcase, and collect

the

ball and spring.

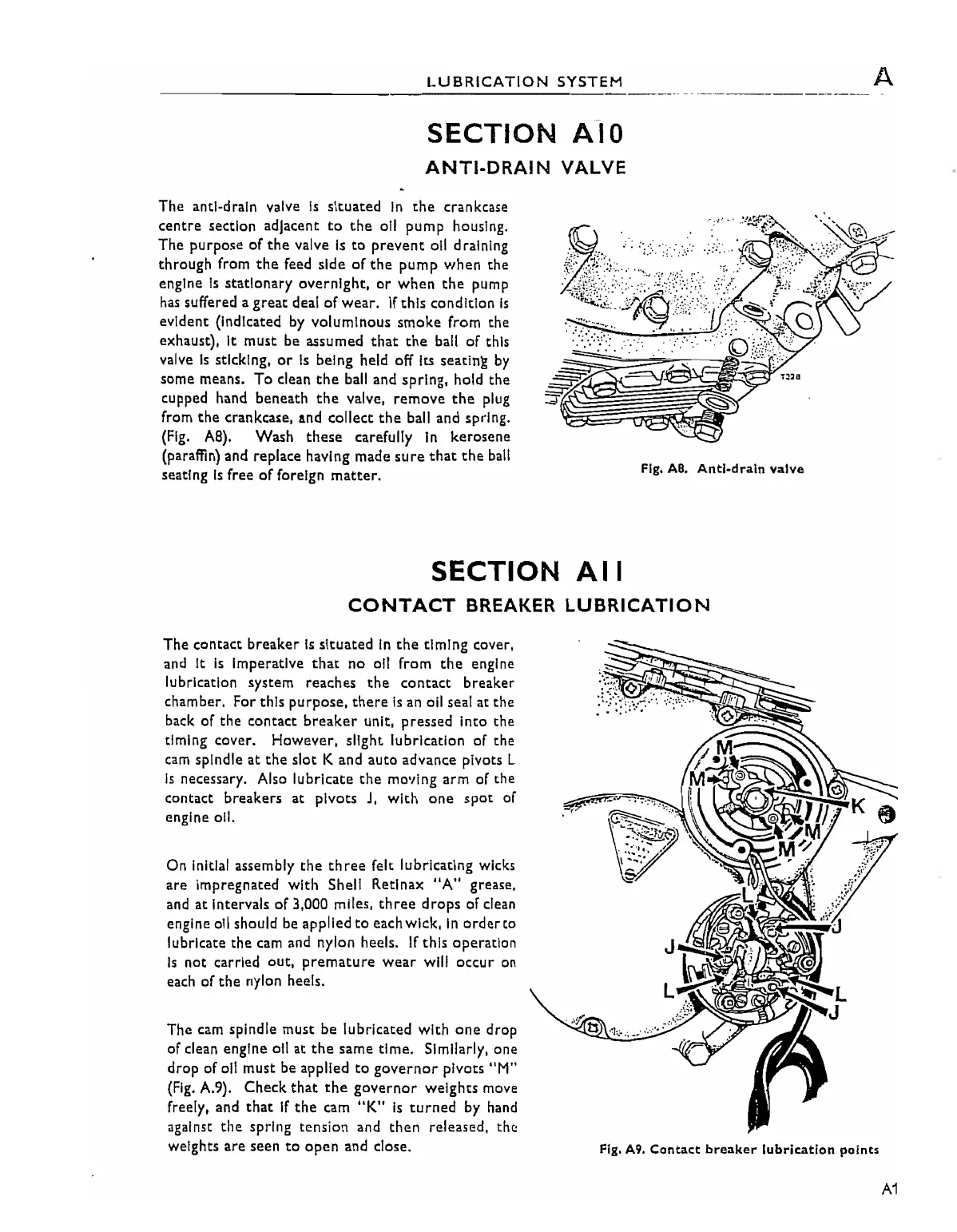

(Fig.

AS).

Wash

these

carefully

In

kerosene

(paraffin) and replace having made

sure

that

the

bail

seating

Is

free

of

foreign

matter.

Fig.

AB.

Anti-drain

valve

SECTION

All

CONTACT

BREAKER

LUBRICATION

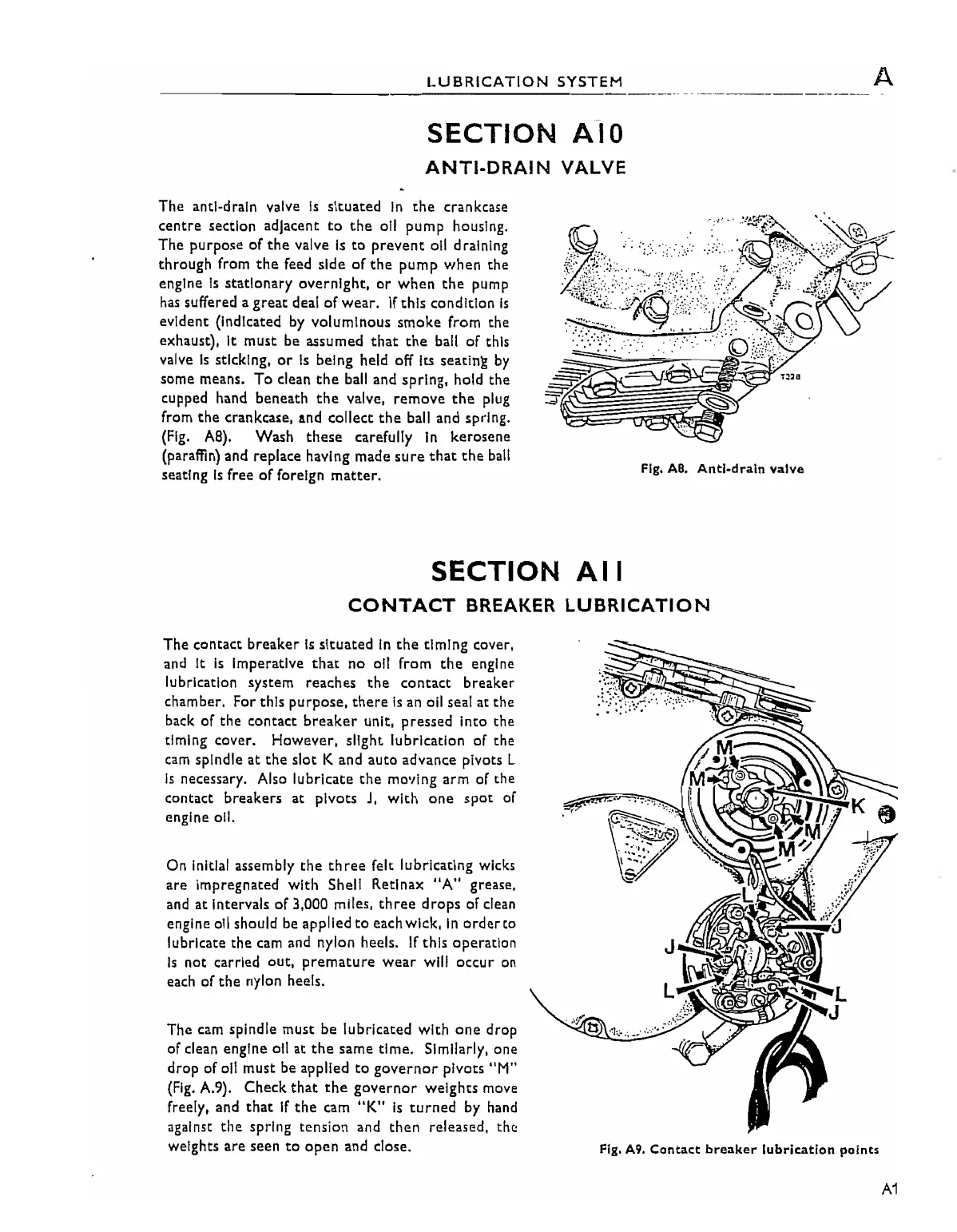

The contact

breaker

Is

situated

In

the

timing cover,

and It

Is

Imperative

that

no

oil from

the

engine

lubrication system reaches

the

contact breaker

chamber. For this purpose,

there

Is

an oil seal at the

back of the contact

breaker

unit, pressed Into the

timing cover. However, slight lubrication of the

cam

spindle

at

the

slot

K and

auto

advance pivots L

Is

necessary. Also lubricate

the

moving

arm

of the

contact breakers at pivots

J,

with

one

spot

of

engine

011.

On Initial assembly

the

three

felt lubricating wicks

are

Impregnated with Shell Retlnax

"A"

grease.

and

at

Intervals of 3,000 miles,

three

drops

of clean

engine oil should be applied

to

each wick,

In

ordereo

lubricate

the

cam and nylon heels.

If

this operation

Is

not carried out, premature

wear

will occur

on

each of

the

nylon heels.

The cam spindle must be lubricated with

one

drop

of clean engine oil

at

the

same time. Similarly, one

drop of oil must be applied

to

governor

pivots "M"

(Fig.

A.9). Check

that

the

governor

weights

move

freely, and

that

If

the

cam

"K"

Is

turned

by hand

against

the

spring tension and

then

released. the

weights

are

seen

to

open

and close.

Fig. A9.

Contact

breaker

lubrication

points

A11

Loading...

Loading...