C

PRIMARY

DRIVE

adjuster C inwards until

the

correct

chain slackness

Is

obtained.

Re-tlghten

the

self-locking

nut

B.

Note

that

the

washer D incorporates a special oil seal

which

must

be

renewed

In

the

event

of

leakage.

It is

most

important

that

the

chain

should

not

be

tight.

When

adjustment

is

completed, replace

the

slotted

Inspection plug.

SECTION C5

TO

ItEMOVE

AND

REPLACE

THE

OUTER

PRIMARY

CHAINCASE

COVER

Fig. C4.

Showing

outer

chalncase

screw

location

,,166

D

F

'.

The

cover

Is

now

free

to

be

removed,

although

It

may

require

a light

tap

with a hide mallet

to

break

the

Joint.

The

gear

shift lever assembly will

remain

with

the

cover

as It

Is

withdrawn

I.e.

In

neutral pc:s\tlon.

Prepare

the

chaincase for refitting

by

reniby~g

ail _

traces

of

the

Joint washer, and

ensure

that

boch

face1i:-,

are

clean and free from

burrs.

Ensure

that

b~th

tubular

locating dowels

are

fitted Into

th~.

two

couter~bored

screw holes on the Inner chaincase.

grease

the

joint

surface, and position

the

gasket.

Assemble

the

cover, with care,

over

the

011

pump

Idler

spindle, clutch pull

rod,

and locating

dowels.

Make

sure

that

the

quadrants on

the

gearshift

spindle

and

the

cross shaft

are

correctly

engaged

with

gear

pedal still

In

neutral position,

ocherwlse

the

gearshift

sequence

will be Incorrect.

Refit

the

remaining screws (See

Fig.

C4

for

correct

positions). Tighten

the

screws

In

a diagonal

pattern

to

avoid distorting

the

chalncase.

Turn

the

clutch

operating

lever clockwise, until Its

arm

contacts:its "stop" boss

in

the housing.

then.

for

correctl!adjustment

of

the

",echanlsm,

refer

to

~

Sectlon.C3.

Refer

to

Section

C4

for

adjusting

the

primary

chain.

Refit

the

footrest,

securing firmly

with

the

large

washer

and bolt. Finally add

~

U.s.

pint

of

the

recommended

grade

of

lubricant

(See

Section

A2).

A

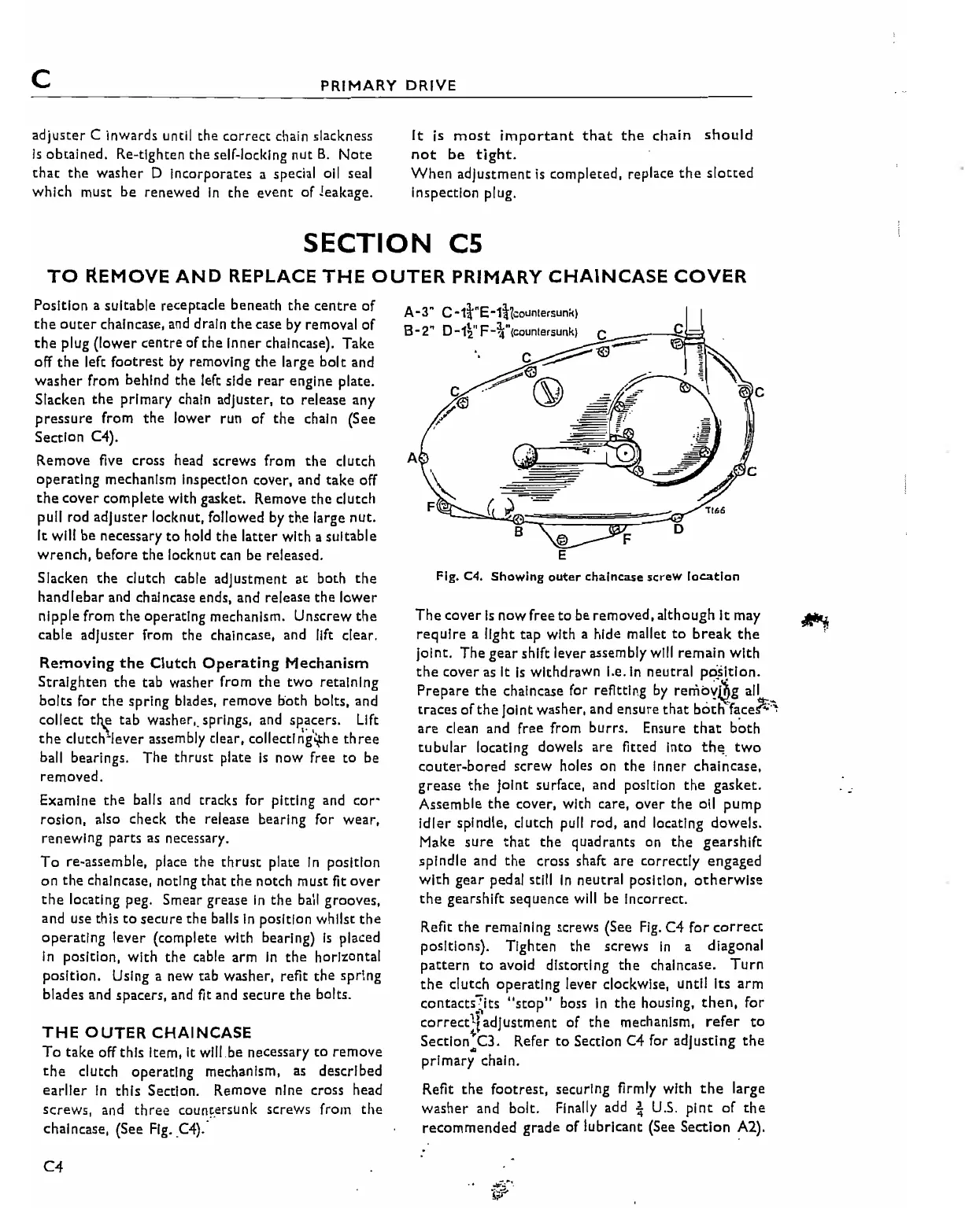

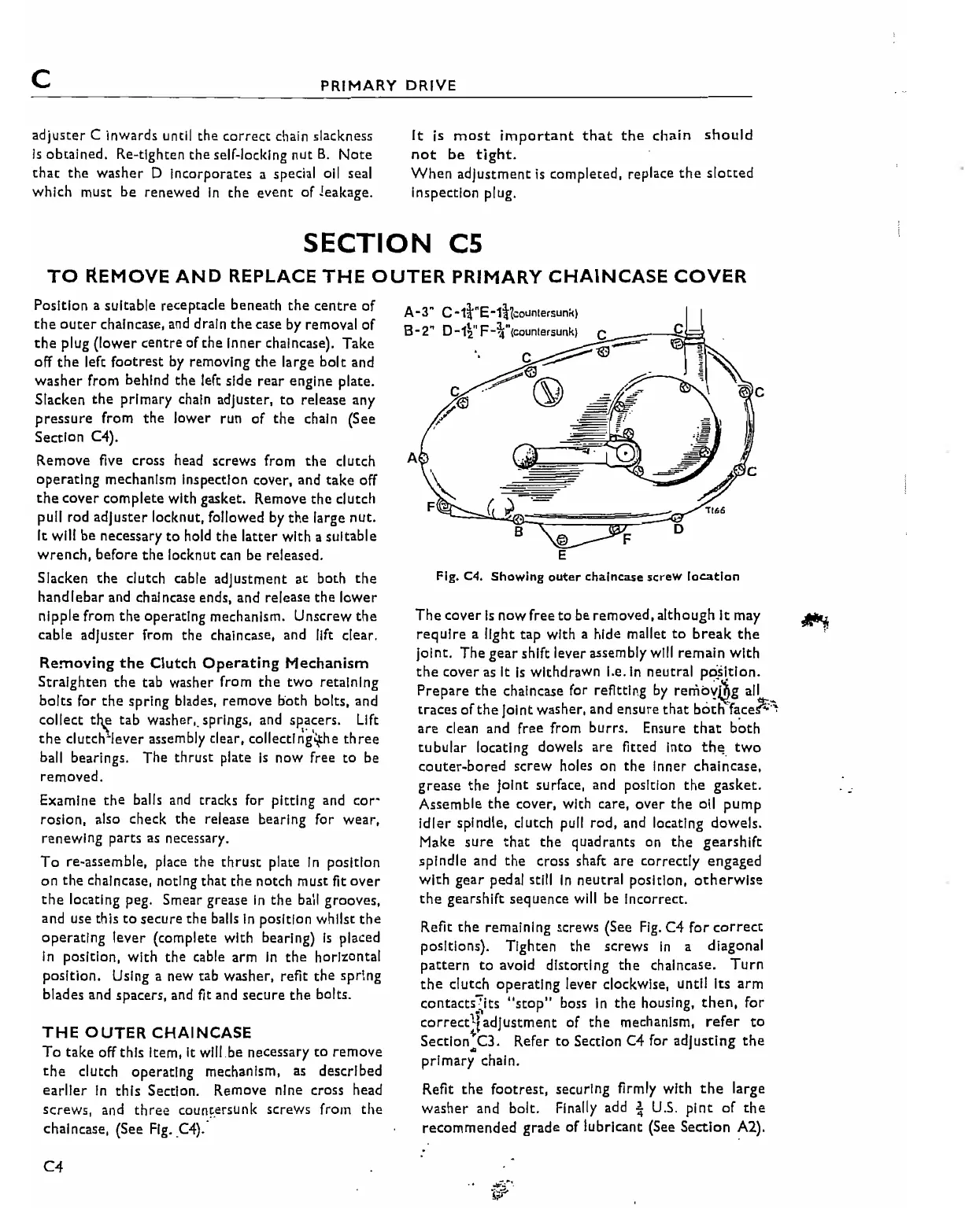

A-3" C-1l'"E-1i!1counte"unkl

B 2

" 0 1'''F 3."

..

..

2 .....

(countersunk)

C

_-=---5Ji:3.

:;;..--

C~@

.......-

........

@ 0

:r-

~

~~_

.' t

THE

OUTER

CHAINCASE

To

take

off this Item,

It

wlll.be necessary

to

remove

the

clutch

operating

mechanism,

as

described

earlier

In

this

Section. Remove nine cross head

screws,

and

three

coun~.ersunk

screWs from

the

chalncase, (See Fig.

C4):

Position a suitable receptacle beneath

the

centre

of

che

outer

chaincase, and drain

the

case by removal

of

the

plug

(lower

centre

of

the

Inner chalncase).

Take

off

the

left

footrest

by removing

the

large

bolt

and

washer

from behind

the

left side

rear

engine plate.

Slacken

the

primary

chain adjuster,

to

release any

pressure

from

the

lower

run

of

the

chain (See

Section C4).

Remove

five cross head screws from

the

clutch

operating

mechanism Inspection cover, and

take

off

the

cover

complete

with gasket. Remove

the

clutch

pull rod

adjuster

locknut, followed by

the

large

nut.

It will be necessary

to

hold

the

latter

with

a suitable

wrench,

before

the

locknut can be released.

Slacken

the

clutch cable

adjustment

at

both

the

handlebar

and chalncase ends, and release

the

lower

nipple from

the

operating mechanism.

Unscrew

the

cable

adjuster

from the chalncase, and lift clear.

Removing

the

Clutch

Operating

Mechanism

Straighten

the

tab washer from

the

two

retaining

bolts

for

the

spring blades,

remove

both

bolts, and

collect

th.t' tab washer,_ springs, and

sp,~~ers.

Lift

the

c1utch~lever

assembly clear,

collectlng"he

three

ball bearings.

The

thrust

plate

Is

now

free

to

be

removed.

'-.

Examine

the

balls

and

tracks for

pitting

and

cor-

rosion, also check the release bearing for wear,

renewing

parts as necessary.

To

re-assemble, place the

thrust

plate

In

position

on

the

chalncase. noting that

the

notch must

fit

over

the

locating peg. Smear grease

In

the

ball grooves,

and use this

to

secure

the

balls

In

position whilst

the

operating

lever

(complete with bearing)

Is

placed

In

position,

with

the

cable arm

In

the

horizontal

position.

Using a new tab washer, refit

the

spring

blades and spacers, and fit and

secure

the

bolts.

C4

:

Loading...

Loading...